Rotational flow grit chamber tail end effluent dissolved oxygen intelligent control system and use method thereof

An intelligent control system, the technology of the cyclone grit chamber, which is applied in the control/manipulation system, water treatment parameter control, chemical instruments and methods, etc., can solve the problems such as the large increase of dissolved oxygen content in the anaerobic tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

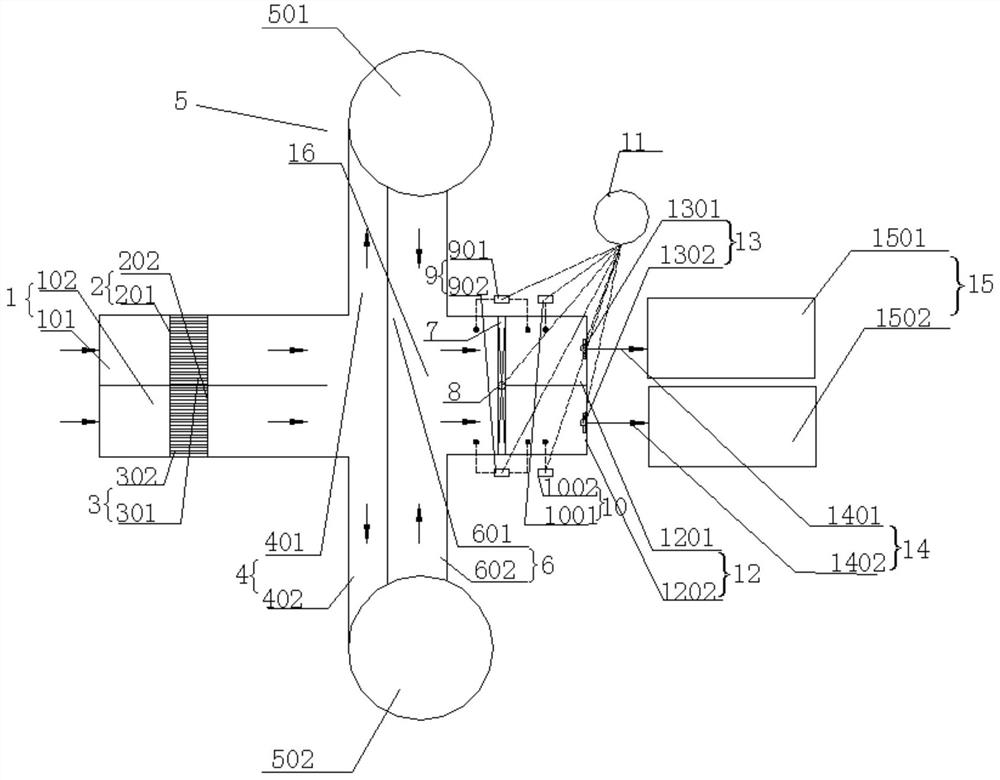

[0028] Such as figure 1 As shown, in order to avoid the phenomenon of oxygenation caused by falling water in the cyclone grit chamber 5, resulting in a large increase in the dissolved oxygen content in the anaerobic pool 15 of the subsequent biochemical treatment process section, the intelligent control system for dissolved oxygen at the end of the cyclone grit chamber 5 , including the main outlet channel 16, the outlet weir 7 and at least two outlet wells 12 (the outlet well I 1201 and the outlet well II 1202), also including the electrically adjustable overflow weir plate 8, at least two ultrasonic liquid level difference gauges 9 (ultrasonic liquid level Differential meter I901 and ultrasonic level difference meter II902), at least two electric adjustment gates 13 (electric adjustment gate I1301 and electric adjustment gate II1302), at least two online dissolved oxygen meters 10 (online dissolved oxygen meter I1001 and online dissolved oxygen meter II1002) and control devi...

Embodiment 2

[0035] The method of using the intelligent control system for dissolved oxygen at the end of the cyclone grit chamber includes the following steps:

[0036] a. The sewage passes through the water inlet 1 (including the water inlet I101 and the water inlet II102) first through the fine grids 3I and II in the fine grid channels 2I and II, and then flows into the cyclone grit chamber 5I through the water inlet channels 4I and II and II;

[0037] b. After the sewage is treated by the cyclone grit chamber 5I and II, it flows into the outlet channels 6I and II, and then the main outlet channel 16I and II converges, and the electric adjustment overflow weir plate 8 on the outlet weir 7 makes the water flow evenly After distribution, it flows into and out of the water wells 12I and II;

[0038] c. The sewage finally passes through the water outlets at the bottom of each outlet well 12I and II, and flows into the corresponding anaerobic pools 15I and II through the outlet pipes 14I an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com