Grinding method of rare earth yttrium-lanthanum composite silicon nitride ceramic

A technology of silicon nitride ceramics and grinding methods, which is applied in the field of ceramic production and grinding, and can solve many problems such as uneven particle size distribution, affecting product quality, and differences in material wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

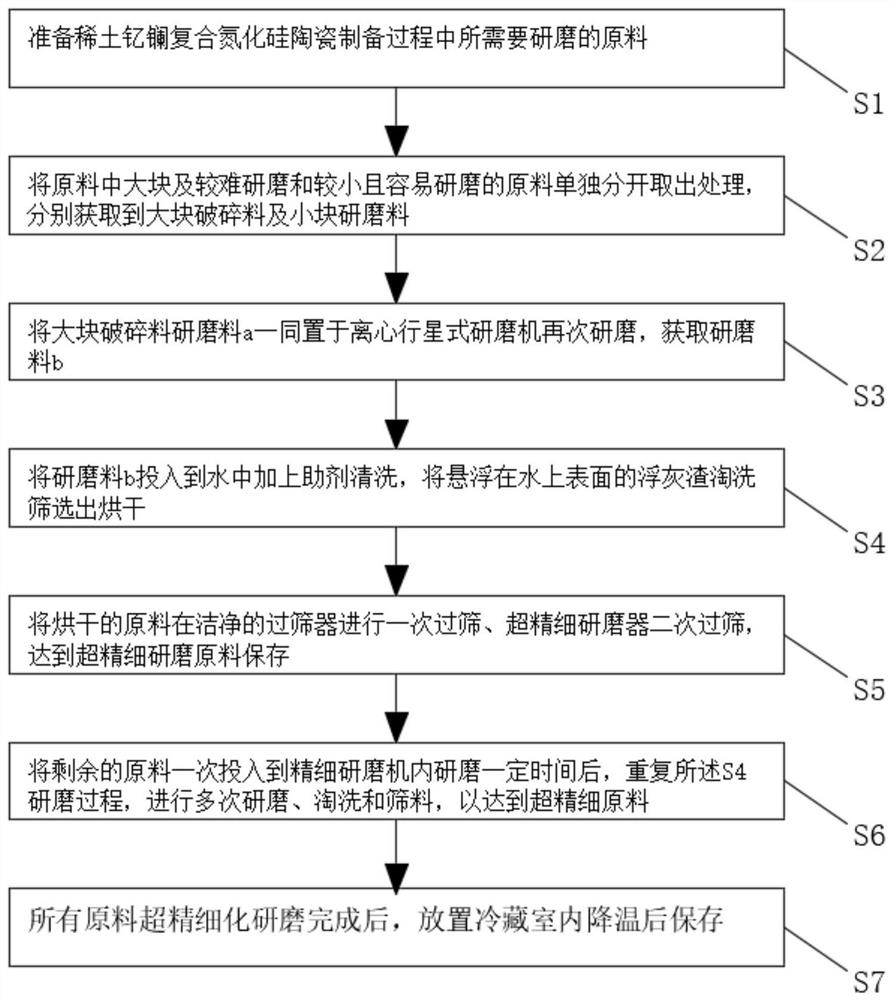

[0031] see figure 1 , the present invention provides a technical solution: a grinding method of rare earth yttrium lanthanum composite silicon nitride ceramics, comprising the following steps:

[0032] S1. Prepare the raw materials required for grinding in the preparation process of rare earth yttrium lanthanum composite silicon nitride ceramics;

[0033] S2. Separately take out and process the bulky and difficult-to-grind raw materials and the small and easy-to-grind raw materials in the raw materials, and obtain the large crushed material and the small grinding material a respectively;

[0034] S3. Put the large pieces of crushed material and abrasive material a together in a centrifugal planetary grinder for regrinding to obtain abrasive material b;

[0035] S4, put the grinding material b into the water and add an auxiliary agent for cleaning, and wash and filter the floating ash suspended on the surface of the water to dry;

[0036] S5. The dried raw materials are sieve...

Embodiment 2

[0047] see figure 1 , the present invention provides a technical solution: a grinding method of rare earth yttrium lanthanum composite silicon nitride ceramics, comprising the following steps:

[0048]S1. Prepare the raw materials required for grinding in the preparation process of rare earth yttrium lanthanum composite silicon nitride ceramics;

[0049] S2. Separately take out and process the bulky and difficult-to-grind raw materials and the small and easy-to-grind raw materials in the raw materials, and obtain the large crushed material and the small grinding material a respectively;

[0050] S3. Put the large pieces of crushed material and abrasive material a together in a centrifugal planetary grinder for regrinding to obtain abrasive material b;

[0051] S4, put the grinding material b into the water and add an auxiliary agent for cleaning, and wash and filter the floating ash suspended on the surface of the water to dry;

[0052] S5. The dried raw materials are sieved...

Embodiment 3

[0063] see figure 1 , the present invention provides a technical solution: a grinding method of rare earth yttrium lanthanum composite silicon nitride ceramics, comprising the following steps:

[0064] S1. Prepare the raw materials required for grinding in the preparation process of rare earth yttrium lanthanum composite silicon nitride ceramics;

[0065] S2. Separately take out and process the bulky and difficult-to-grind raw materials and the small and easy-to-grind raw materials in the raw materials, and obtain the large crushed material and the small grinding material a respectively;

[0066] S3. Put the large pieces of crushed material and abrasive material a together in a centrifugal planetary grinder for regrinding to obtain abrasive material b;

[0067] S4, put the grinding material b into the water and add an auxiliary agent for cleaning, and wash and filter the floating ash suspended on the surface of the water to dry;

[0068] S5. The dried raw materials are sieve...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap