Low-frequency large-stroke quasi-zero stiffness vibration isolation device

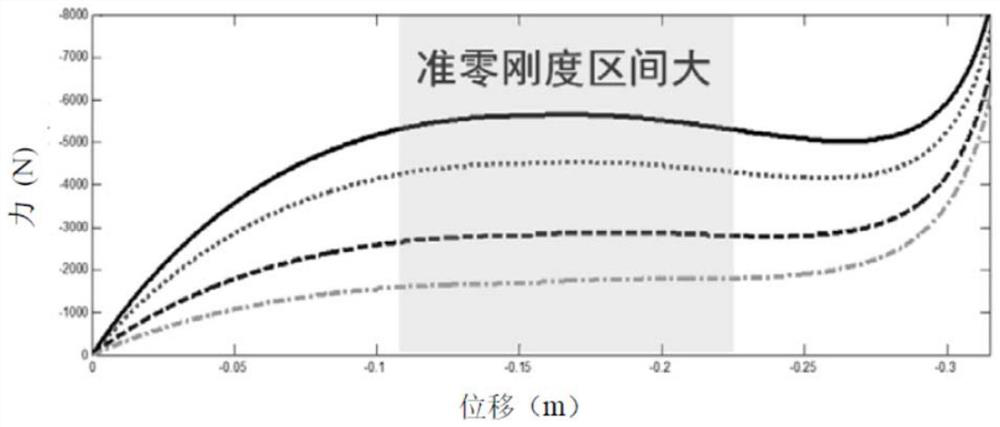

A quasi-zero stiffness and large stroke technology, applied in the field of low-frequency and large-stroke quasi-zero stiffness vibration isolation devices, it can solve the problem of small displacement stroke, the vibration isolation effect is sensitive to the external environment and the load, and cannot adapt to harsh and complex actual working conditions. and other problems, to achieve the effect of high bearing capacity, stable and effective low-frequency vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

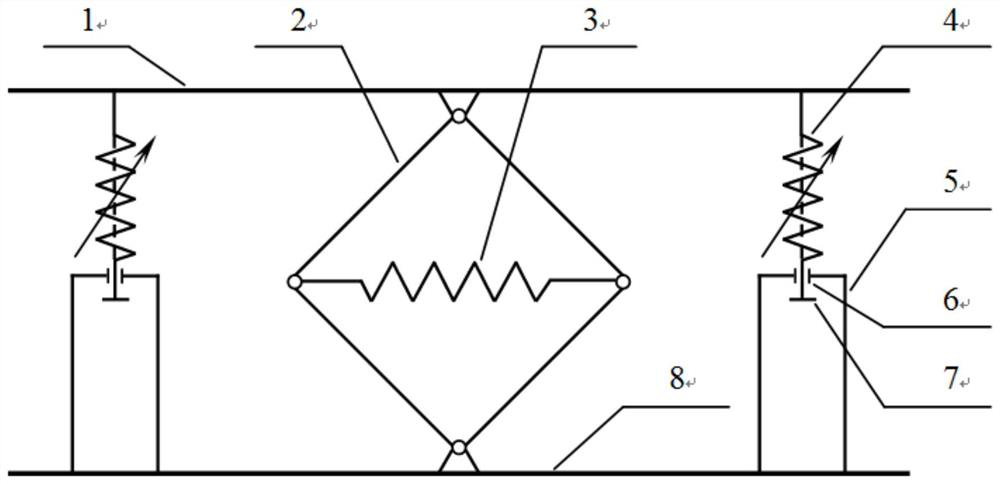

[0026] Specific implementation mode one: refer to figure 1 To illustrate this embodiment, this embodiment provides a low-frequency large-stroke quasi-zero-stiffness vibration isolation device, the vibration isolation device includes an upper platform 1, a lower platform 8, a diamond-shaped spring structure and two adjustable limit support structures;

[0027] The upper platform 1 and the lower platform 8 are arranged parallel to each other up and down, the diamond spring structure is arranged between the upper platform 1 and the lower platform 8, and the top of the diamond spring structure is fixedly connected with the center point of the lower surface of the upper platform 1, and the diamond spring structure The bottom of the bottom is fixedly connected to the center point of the upper surface of the lower platform 8, and the two adjustable limit support structures are relatively arranged at both ends of the diamond spring structure, and the bottom of each adjustable limit sup...

specific Embodiment approach 2

[0029] Specific implementation mode two: refer to figure 1 Describe this embodiment, this embodiment is to further limit the upper platform 1 described in the first specific embodiment, in this embodiment, the structure of the upper platform 1 and the lower platform 8 are the same, both are rectangular platforms. Other compositions and connection methods are the same as those in Embodiment 1.

[0030] Such setting ensures that the vibration isolation device provided by the present invention has good supportability and is more stable in experimental work.

specific Embodiment approach 3

[0031] Specific implementation mode three: refer to figure 1 Describe this embodiment. This embodiment is to further limit the rhombic spring structure and the two adjustment limit support structures described in the second specific embodiment. In this embodiment, the rhombus spring structure and the two adjustment limit support structures Located on the center line of the lower platform 8 along the width direction. Other compositions and connection methods are the same as those in the second embodiment.

[0032] In this embodiment, the diamond-shaped spring structure and the two adjustable limit support structures are located on the same center line, which is beneficial to ensure the coordination of the vibration isolation device during work and avoid the platform from shifting after the weight is applied.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com