Valve with anti-freezing function

A valve and function technology, applied in the field of valves with anti-freeze function, can solve the problems of repeated operation of electric heaters, affecting the service life, stop, etc., to achieve the effect of improving the anti-freezing effect, ensuring the stability and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

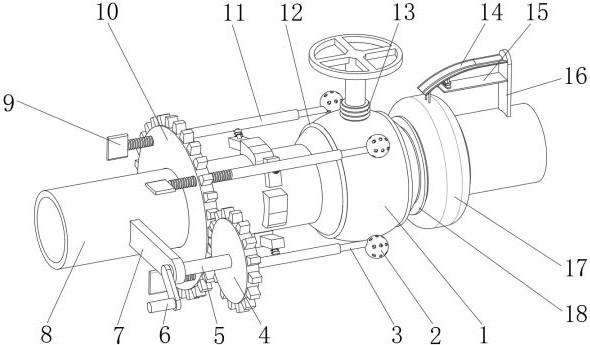

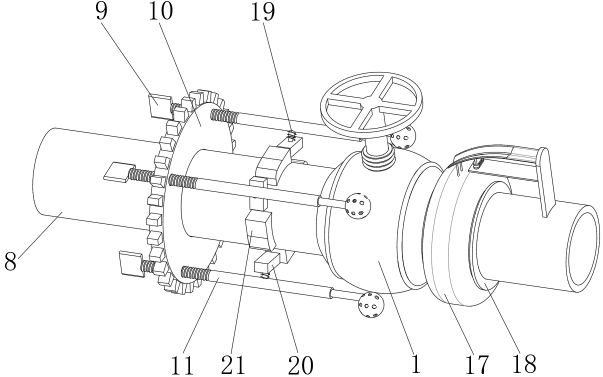

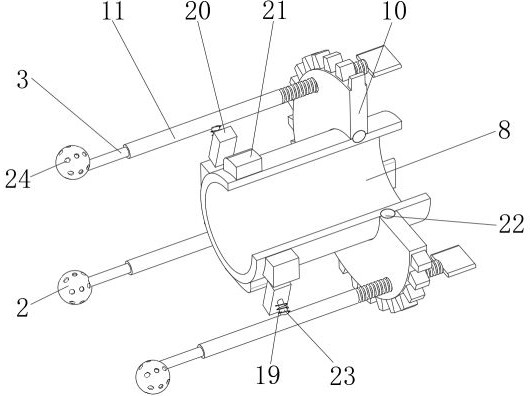

[0033] A valve with antifreeze function, such as Figure 1-4As shown, it includes a valve body 1 installed on the delivery pipe 8, the outer wall of the valve body 1 is embedded with a heating wire assembly, and the heating wire assembly includes a first heating wire 12 installed on the surface of the valve body 1 and an installation The second heating wire 13 at the rotation position of the valve stem in the valve body 1, the control mechanism for controlling the operation of the first heating wire 12 and the second heating wire 13 is installed on the delivery pipe 8, and the outer wall of the delivery pipe 8 is integrated Two spacer rings 18 are provided, and an air bag 17 is sleeved on the outside of the delivery pipe 8, and the air bag 17 is located between the two spacer rings 18. The control mechanism includes a shrapnel bracket 14, a support plate 15 and a mounting frame 16. One side of the outer wall of the shrapnel bracket 14 and the support plate 15 is installed on t...

Embodiment 2

[0044] A valve with antifreeze function, such as Figure 5 As shown, in order to facilitate the automatic control of antifreeze; this embodiment makes the following improvements on the basis of embodiment 1: the drive mechanism includes a motor 30, a connecting shaft 5 and a driving gear 4, and the connecting shaft 5 is installed on the The outer wall of one side of the delivery pipe 8, the driving gear 4 is fixed on the outer wall of one end of the connecting shaft 5 by screws, and the driving gear 4 is meshed with the driven gear 10; the motor 30 is fixed on the outer wall of the rotating shaft frame 7 by screws, and the The output end is rotatably connected to the outer wall of one end of the connecting shaft 5 through a coupling, and the two conductive plates 26 are connected to the control circuit of the motor 30 .

[0045] When this embodiment is in use, since the two conductive sheets 26 are connected to the motor 30, the deformation of the airbag 17 is used to control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com