A short-circuit discharge device for polypropylene film capacitor

A technology of polypropylene film and discharge device, which is applied to circuits, coupling devices, devices with flexible leads, etc., can solve problems such as poor user experience, too long wires, potential safety hazards, etc., and improve practicability and work efficiency , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

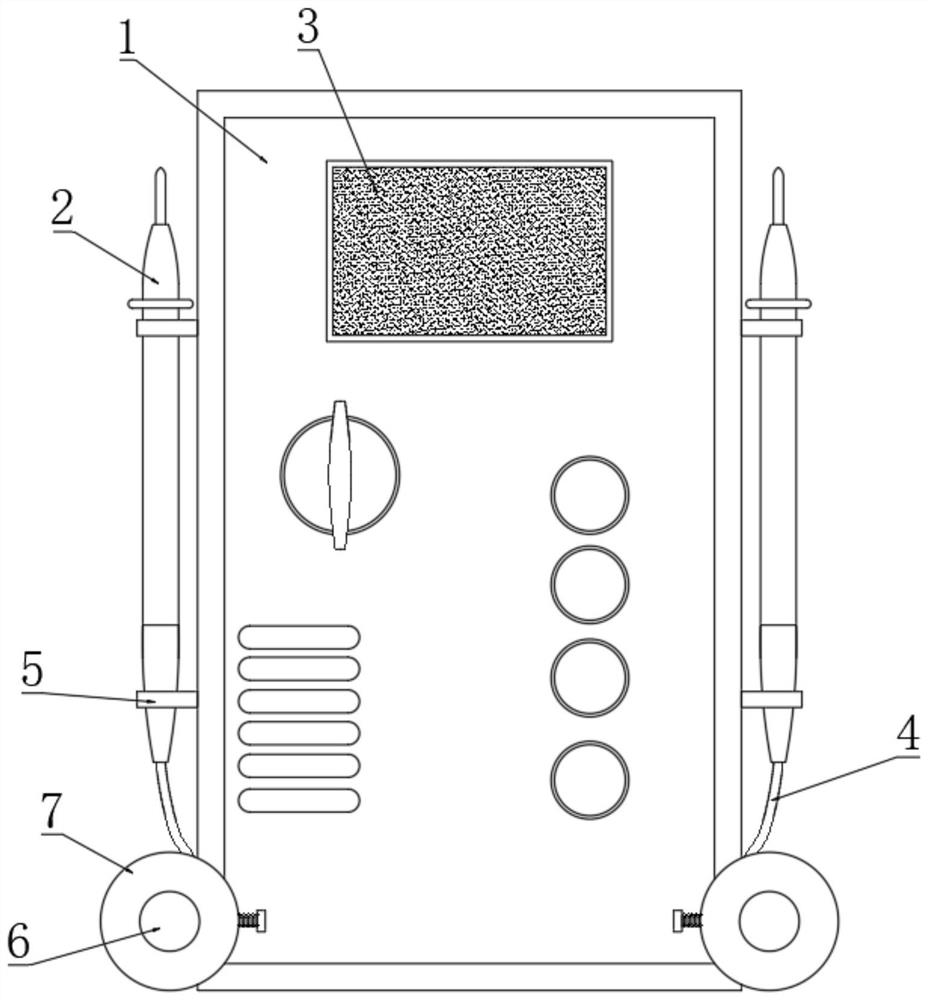

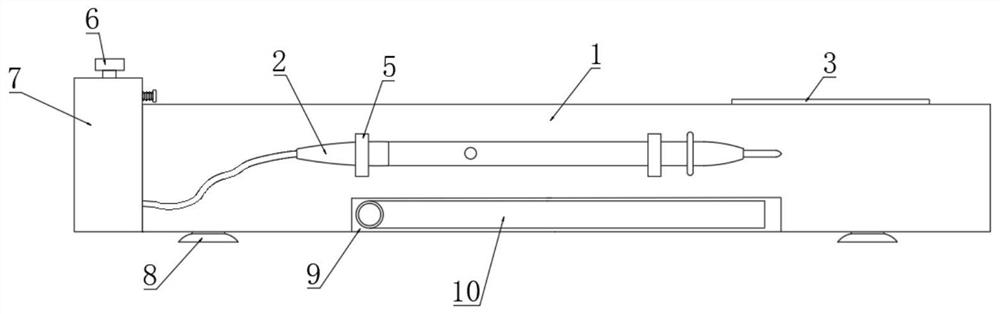

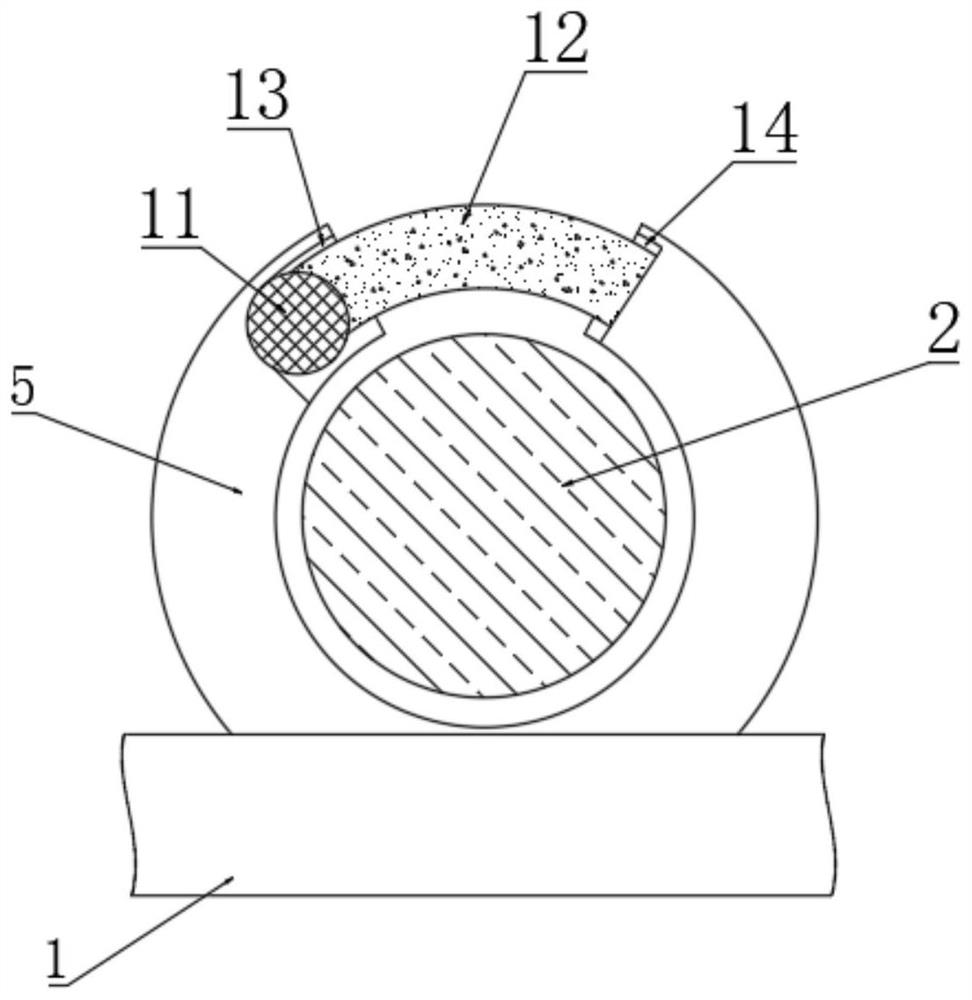

[0028] Such as Figure 1-Figure 6 As shown, a short-circuit discharge device for polypropylene film capacitors includes a capacitor discharge device main body 1 and a discharge pen 2. Both sides of the bottom end of the capacitor discharge device main body 1 are fixedly connected with symmetrical limit tubes 7, and the ends of the limit tube 7 The inner bottom surface is fixedly connected with a bearing 19, and the middle rotation of the bearing 19 is provided with a rotating rod 20, and the surface of the rotating rod 20 is wound with an electric wire 4, and one end of the electric wire 4 runs through the limiting tube 7, and the electric wire 4 extends to the outside of the limiting tube 7 , the electric wire 4 is fixedly connected with the discharge pen 2, the top of the limit tube 7 is pierced with a knob 6, and the end of the knob 6 is fixedly connected with the rotating rod 20, and the outer surface of the rotating rod 20 is fixedly connected with the limit block 18, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com