Glass suction cup mechanical arm

A manipulator and suction cup technology, applied in the direction of manipulators, conveyor objects, furnaces, etc., can solve the problems of inability to meet the special design requirements of customers, the manipulator cannot adjust the spacing of suction cups, and is not suitable for handling shaped glass plates, etc., to achieve stable, reliable and practical transportation. Strong, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

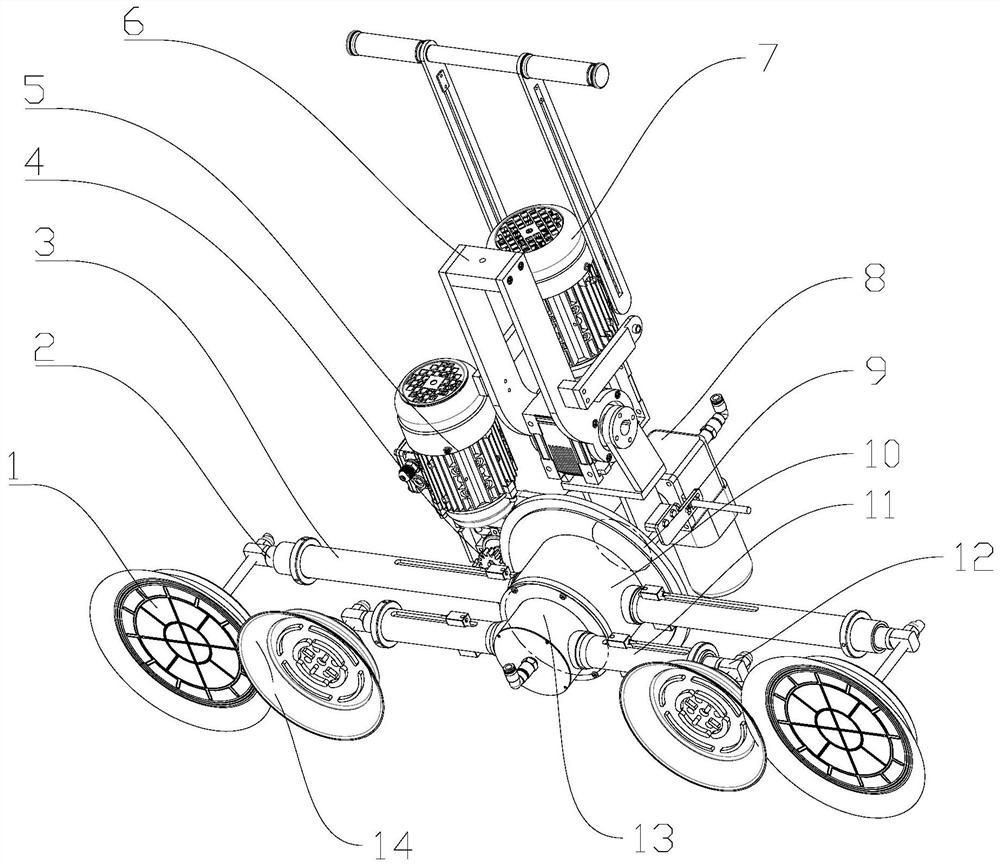

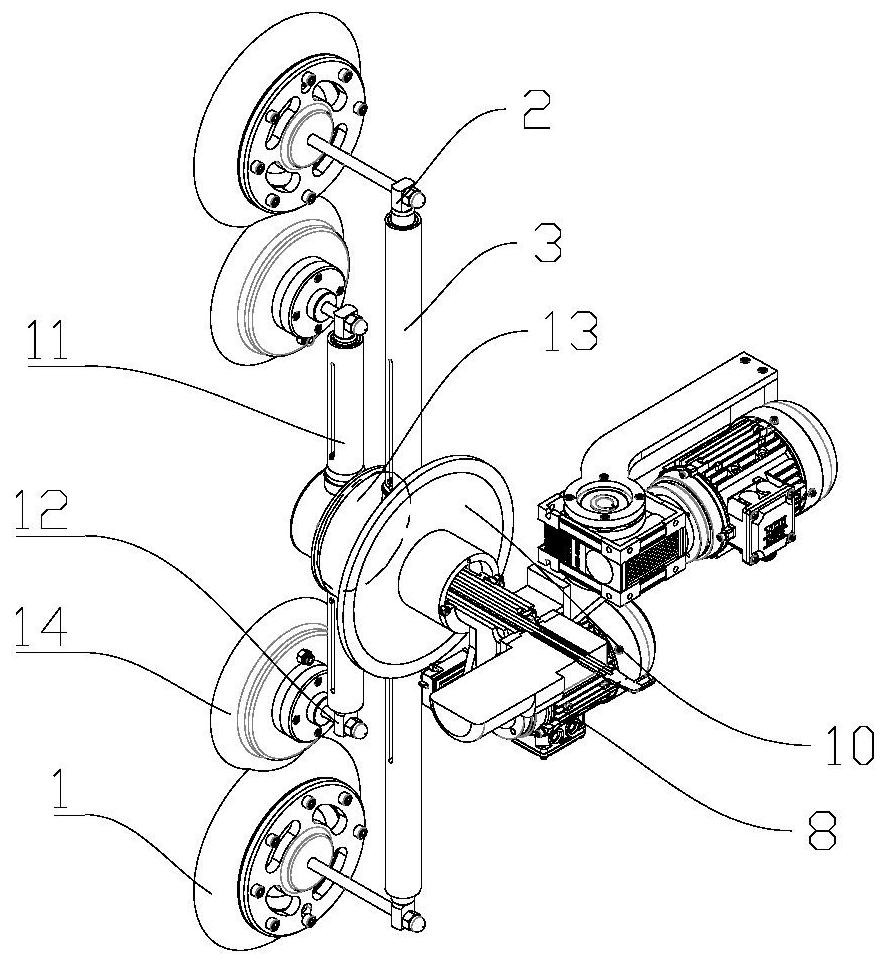

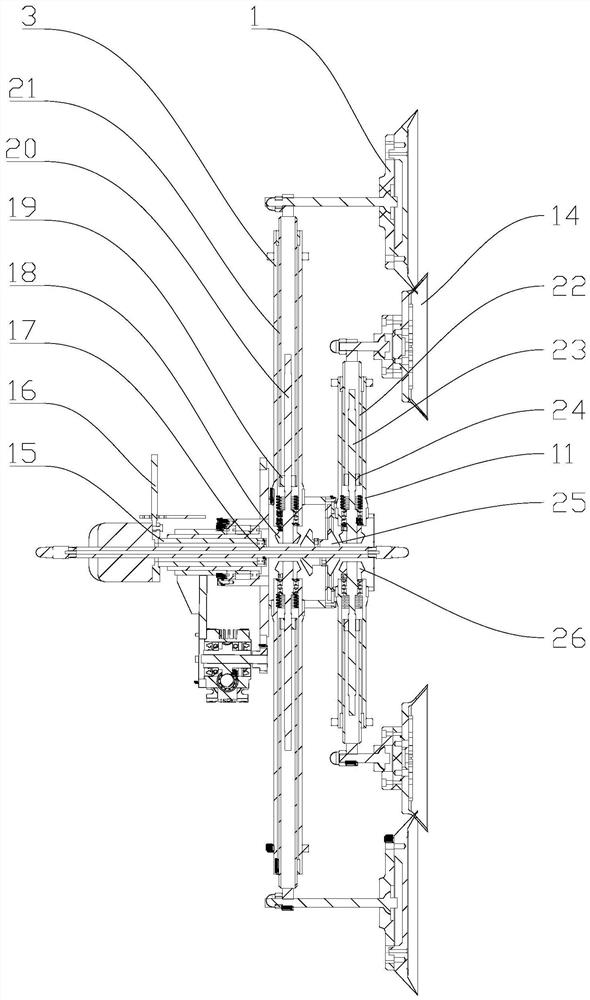

[0030] Such as Figure 1-6 As shown, a glass suction cup manipulator includes a front suction cup frame main body 13, a rear suction cup frame main body 10 and a suction cup adjustment shaft 17, and the suction cup adjustment shaft 17 passes through the front suction cup frame main body 13, the rear suction cup frame main body 10, and the front suction cup frame main body 13, a plurality of front fixed sleeve rods 11 are installed, and the front telescopic rod 12 and the front adjustment mechanism connected to each other are installed in the front fixed sleeve rod 11. The end of the front telescopic rod 12 is equipped with a front suction cup 14, and the rear suction cup holder main body 10 A plurality of rear fixed sleeve rods 3 are installed on the rear fixed sleeve rod 3, and the rear telescopic rod 2 and the rear adjustment mechanism connected to each other are installed in the rear fixed sleeve rod 3. The end of the rear telescopic rod 2 is equipped with a rear suction cup...

Embodiment 2

[0039] Such as Figure 1-6 As shown, on the basis of the above-mentioned embodiment 1, this embodiment provides a preferred structure that can facilitate the removal of the suction cup manipulator, that is, it also includes a corner reducer 5, the input end of the corner reducer 5 is connected to a corner motor, and the output end Be connected with rotating shaft, and rotating shaft is connected with sucker frame boom 6. When transporting the placed glass plates, the suction cup holder arm 6 is connected with the lifting device. When the space position of the suction cup holder arm 6 needs to be changed, the corner motor is operated to rotate by operating the external controller, and the corner motor drives the corner reducer 5 Operation, the corner reducer 5 drives the rotating shaft to rotate again, and the rotating shaft drives the suction cup hanger arm 6 to rotate again, so that the overall structure of the sucker hanger arm can be adjusted to be placed flat or in a cubic...

Embodiment 3

[0042] Such as Figure 1-6 As shown, on the basis of the above-mentioned embodiments 1 and 2, this embodiment provides a preferred structure that can make the relative rotation between the front suction cup 14 and the rear suction cup 1, that is, it also includes the rotation speed reducer 7, and the input end of the rotation speed reducer 7 A rotary motor is connected, the output end is connected with an output shaft, and a rotary gear 4 is installed on the output shaft, and the rear end of the rear sucker frame main body 10 is equipped with 4 turns of the rotary gear meshed with the rotary gear 4 . When it is necessary to change the angle of the front sucker 14 and the rear sucker 1 in space, the rotation of the rotary motor can be controlled by an external controller, and the rotary motor drives the rotary reducer 7 and the output shaft to rotate in turn, and the output shaft drives the rotary gear 4 to rotate again. The rotating gear 4 drives the rotating ring gear 9 to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com