Composite base material root resistant waterproof sheet material and preparation method thereof

A root puncture-resistant and waterproof sheet technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of large performance differences between metals and polymers, poor adhesion and dimensional stability, easy Problems such as peeling and disengagement can be solved to meet special design requirements, good integration effect, and not easy to delaminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

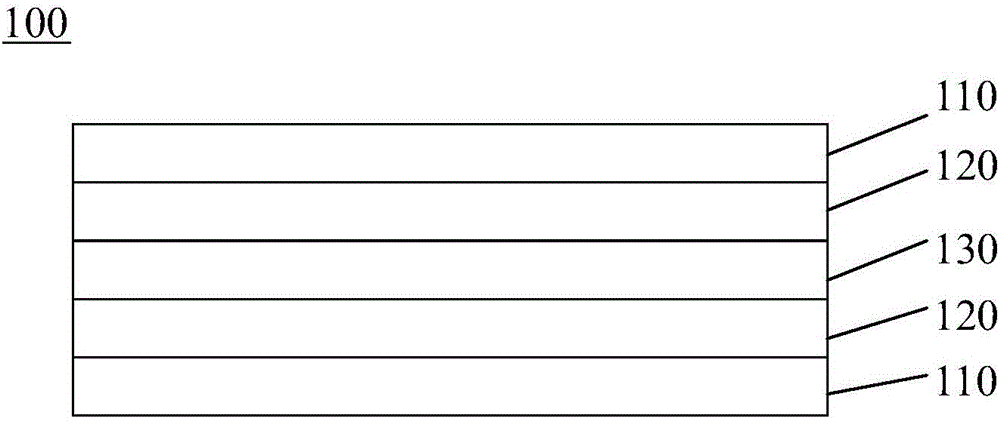

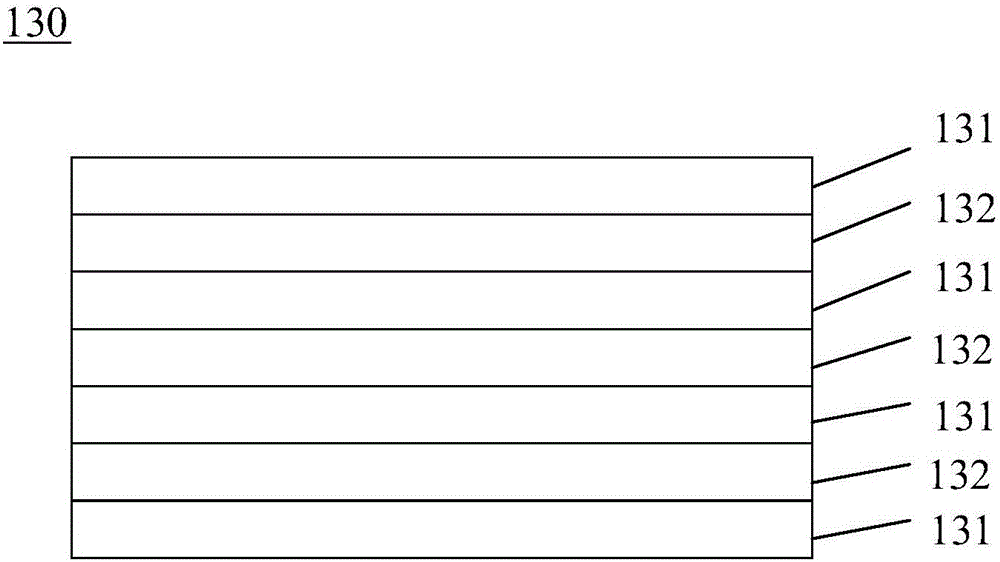

[0028] refer to figure 1 , the composite base root puncture-resistant waterproof sheet 100 of the present embodiment is the outer layer 110, the buffer layer 120, the base layer 130, the buffer layer 120 and the outer layer 110 from top to bottom, wherein the outer layer of non-woven fabric accounts for the total mass 60% of the buffer layer is a modified polymer mixed polyethylene, which is composed of 50% linear low density polyethylene, 35% metallocene and 15% ethylene acrylic acid. refer to figure 2 The base layer 130 is alternately stacked with nylon layers 131 and heat-sealing layers 132 to form a seven-layer structure, and the nylon layers 131 are connected to the buffer layer 120 . In addition, the base layer 130 can also be designed as a structure with more than 7 layers, such as an 11-layer structure. The thickness ratio of the buffer layer 120 to the base layer 130 is 4:13; in the base layer 130 , the thickness ratio of the nylon layer 131 to the heat-sealing lay...

Embodiment 2

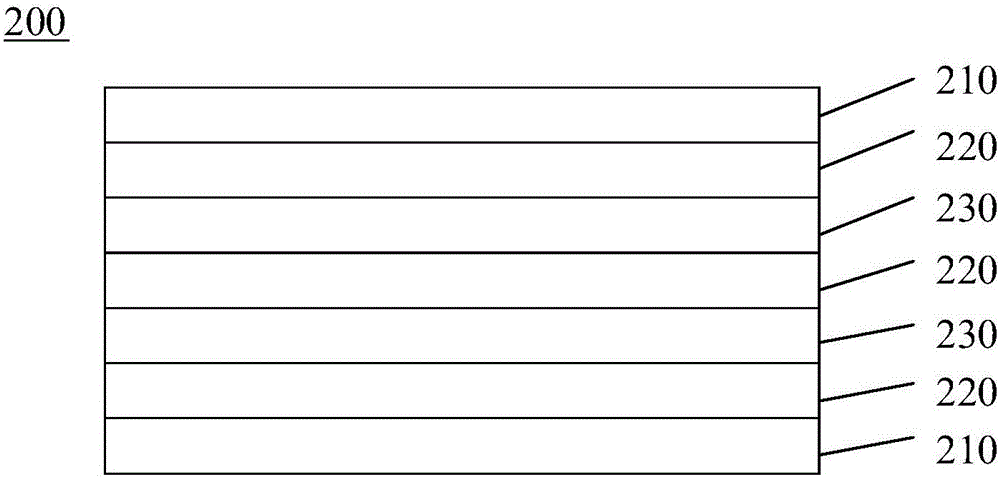

[0030] refer to image 3 , the composite base root puncture-resistant waterproof sheet 200 of the present embodiment is the outer layer 210, the buffer layer 220, the base layer 230, the buffer layer 220, the base layer 230, the buffer layer 220 and the outer layer 210 from top to bottom, wherein The outer layer of non-woven fabric accounts for 50% of the total mass, and the buffer layer 220 is a modified polymer mixed polyethylene, which is composed of 60% linear low density polyethylene, 25% metallocene and 15% ethylene acrylic acid. The structure of the tire base layer 230 is the same as in Embodiment 1. In addition, the base layer 230 can also be designed as a structure with more than 7 layers, such as an 11-layer structure. The thickness ratio of the buffer layer 220 to the base layer 230 is 1:4; in the base layer 230, the thickness ratio of the nylon layer to the heat-sealing layer is 1:2 and the nylon layer accounts for more than 30% of the weight of the base layer. I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com