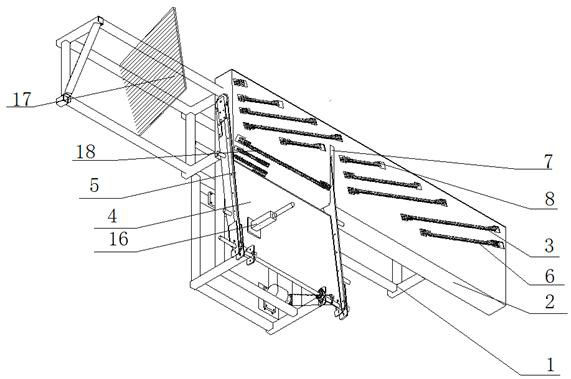

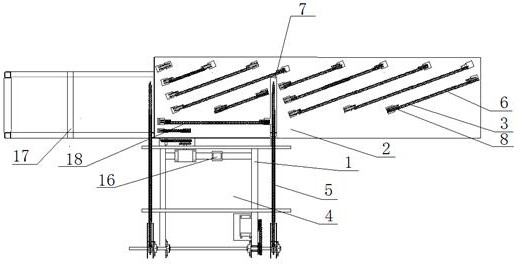

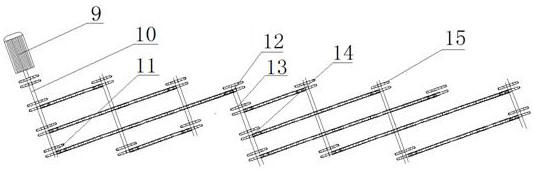

Large saw plate connecting machine

A technology of plate machine and transportation platform, applied in the field of large sawing and joining machine, can solve the problems of workers operating close to large saws, slow feeding speed of employees, waste of labor and other problems, so as to facilitate follow-up maintenance, improve production efficiency, and eliminate production. effect of accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] The wooden boards cut by the previous process arrive at the transport platform 2. Driven by the inclined chain 6 on the transport platform 2, the wood moves forward while tilting towards the lifting platform 4. The third sprocket group 18 transports the wood in parallel. A baffle plate 17 is set in front of the transport platform 2 to prevent the timber from falling, and the plank is translated to the top of the second sprocket set 5. At this time, the first sprocket set 3 and the third sprocket set 18 stop running, and the cylinder 16 Jack up the lower side of the lifting platform 4, the lifting platform 4 is level with the transport platform 2, the second sprocket group 5 also rises and starts to run, and the plank on the chain of the second sprocket group 5 is transported through the lifting platform 4 Walk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com