Driving torque optimization control method of pure electric vehicle

A pure electric vehicle, driving torque technology, applied in electric vehicles, control drives, control devices, etc., can solve the problems of low motor efficiency, power battery overcurrent, irreversible damage, etc., to reduce average power consumption and prolong service life. , to avoid the effect of over-discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

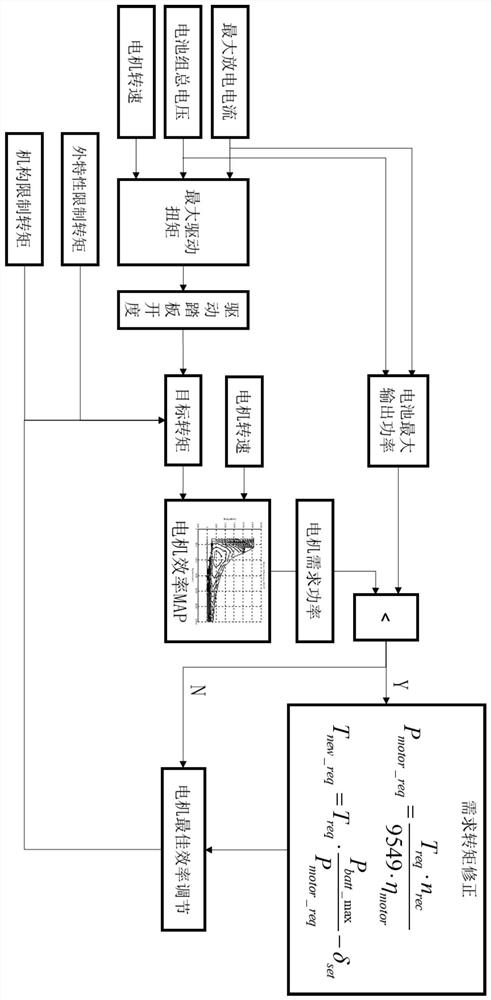

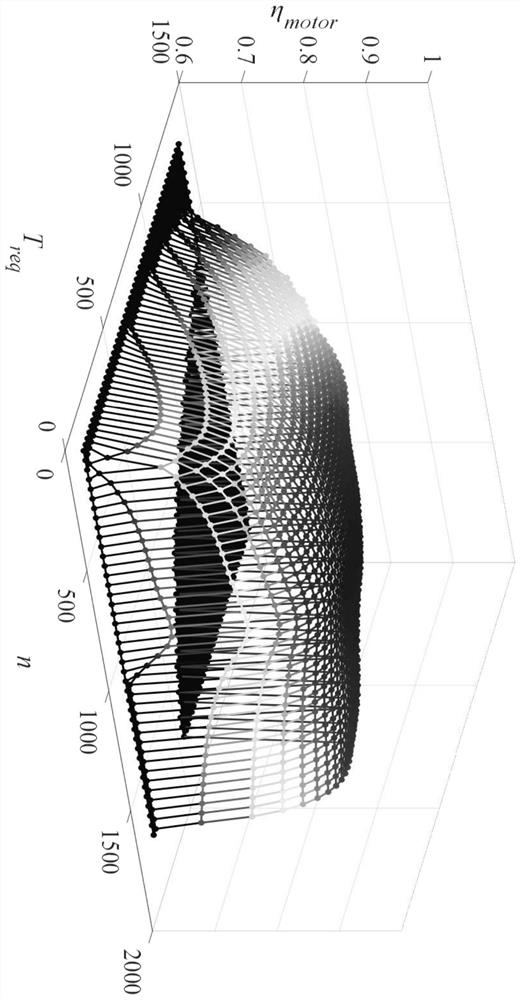

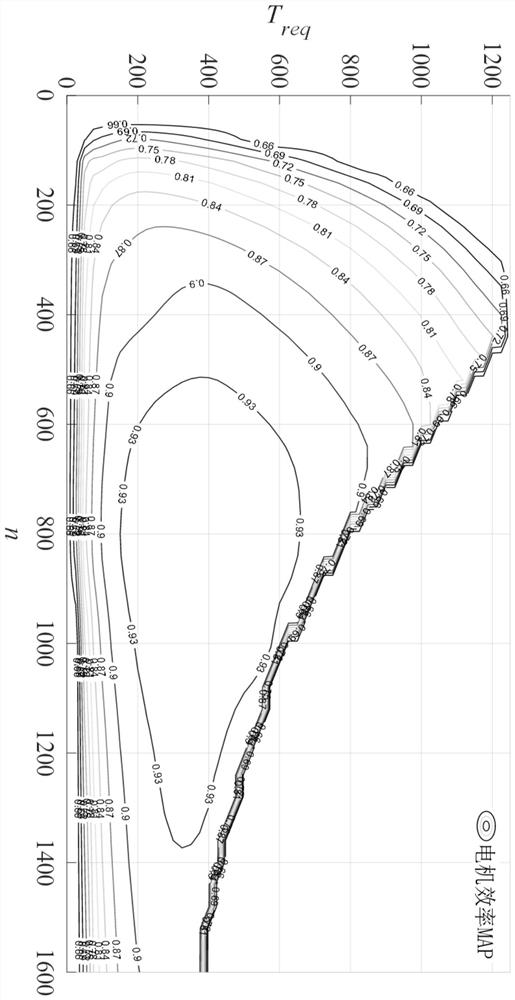

[0034] A flow chart of a driving torque optimization control method for a pure electric vehicle of the present invention is shown in the attached figure 1 As shown, first obtain the maximum discharge current of the battery calculated by the battery management system, combine the total battery voltage and battery efficiency to obtain the maximum output power of the battery, and then combine the motor speed to obtain the maximum output torque, and then multiply it by the opening of the driving pedal, and The target torque is calculated using the external characteristic limited torque and mechanism limited torque as constraints. Calculate the current motor efficiency by inputting the motor speed and target torque, further calculate the motor demand power and compare it with the battery maximum output power, if it exceeds the battery output capacity, correct the demand tor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com