While-drilling ultrasonic borehole diameter data correction method

A data correction and ultrasonic technology, applied in special data processing applications, earthwork drilling, wellbore/well components, etc., can solve the problems of poor data reliability and low correction accuracy, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for correcting ultrasonic caliper data while drilling, comprising the following steps:

[0033] a. In a depth interval, use the ultrasonic caliper tool while drilling to measure the caliper and collect the ultrasonic caliper waveform;

[0034] b. At a depth point, the arrival time t of the borehole reflection wave and the energy E1 of the borehole reflection wave are extracted by the energy envelope method, and the borehole diameter r is calculated according to the arrival time t of the borehole reflection wave and the ultrasonic wave velocity v in the well fluid.

[0035]

[0036] c. Use the transmitted wave energy E2 to normalize the borehole wall reflected wave energy E1 to obtain the actual attenuation coefficient k;

[0037] k=E1 / E2 Formula 2

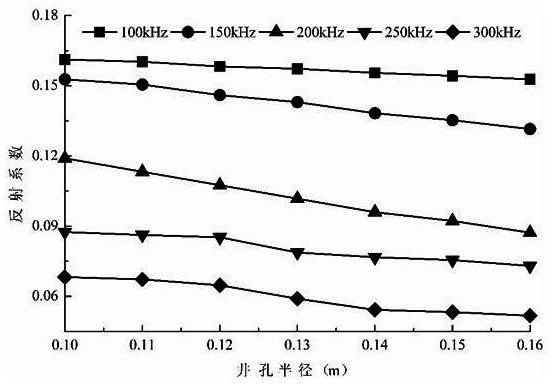

[0038] d. Establish a physical model based on the excitation frequency, mud parameters, formation parameters, tool size, and borehole caliper r during the actual caliper logging while drilling, use finite differ...

Embodiment 2

[0043] A method for correcting ultrasonic caliper data while drilling, comprising the following steps:

[0044] a. In a depth interval, use the ultrasonic caliper tool while drilling to measure the caliper and collect the ultrasonic caliper waveform;

[0045] b. At a depth point, the arrival time t of the borehole reflection wave and the energy E1 of the borehole reflection wave are extracted by the energy envelope method, and the borehole diameter r is calculated according to the arrival time t of the borehole reflection wave and the ultrasonic wave velocity v in the well fluid.

[0046]

[0047] c. Using the transmitted wave energy E2 to normalize the borehole wall reflected wave energy E1 to obtain the actual attenuation coefficient k,

[0048] k=E1 / E2 Formula 2

[0049] d. Establish a physical model based on the excitation frequency, mud parameters, formation parameters, tool size, and borehole caliper r during the actual caliper logging while drilling, use finite diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com