Diesel engine air guide device for agricultural machinery

An air guiding device and agricultural machinery technology, applied in the direction of mechanical equipment, machine/engine, charging system, etc., can solve the problems of inconvenient operation, clogged filter, inconvenient users, etc., and achieve noise reduction, stable up and down movement, and timely cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

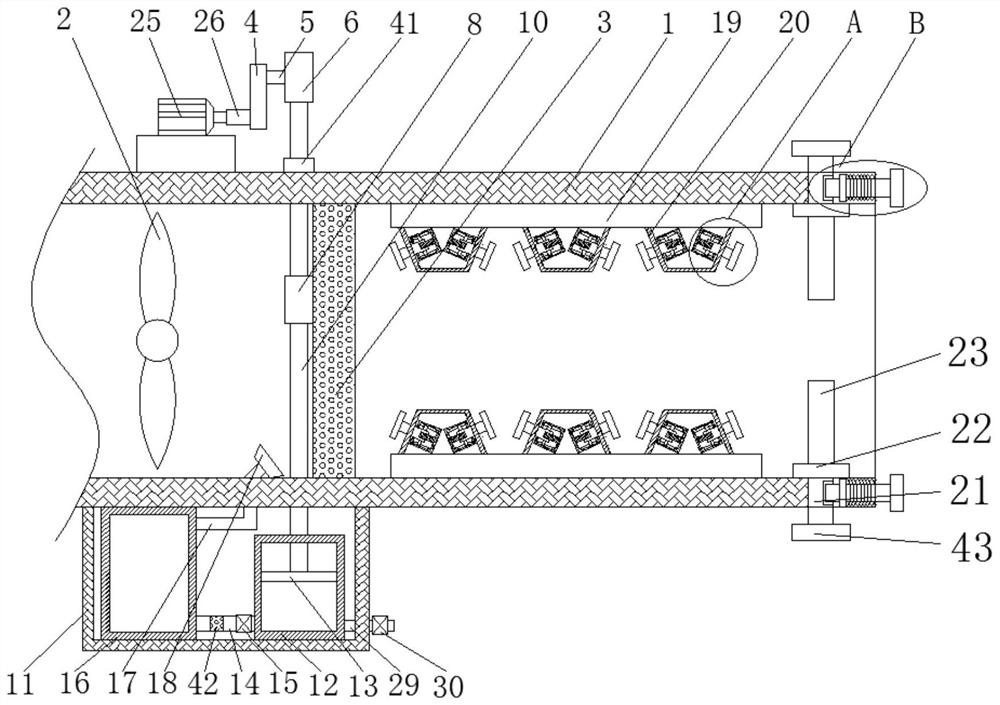

[0031] see Figure 1-5 According to an embodiment of the present invention, an air guide device for diesel engines for agricultural machinery includes an air guide channel 1, a fan 2 is installed in the air guide channel 1, the fan 2 is connected to an external power supply, and the inside of the air guide channel 1 A filter screen 3 is fixedly connected, and a drive mechanism is connected to the top of the air guiding channel 1, and a transmission rod 4 is fixedly connected to the output end of the drive mechanism, and a sliding rod 4 is fixedly connected to an end of the transmission rod 4 away from the transmission mechanism. Rod 5, the surface of the slide rod 5 is slidably connected with a horizontal slide rail 6, and the bottom end of the horizontal slide rail 6 is fixedly connected with a movable rod 7, and the bottom end of the movable rod 7 runs through the air guide channel 1 and A cleaning rod 8 is fixedly connected, the bottom end of the cleaning rod 8 is fixedly c...

Embodiment 2

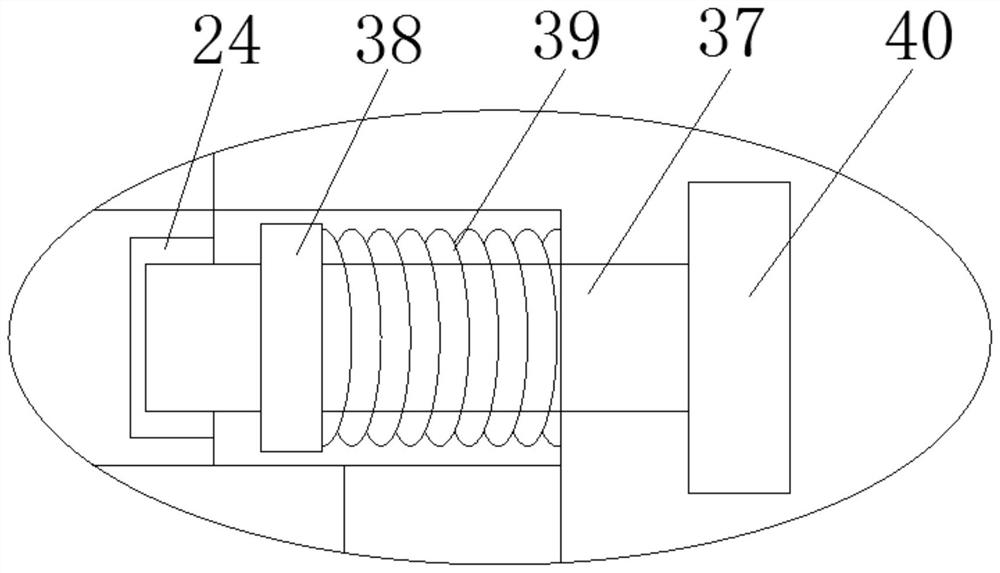

[0034] see Figure 1-5, for the driving mechanism, the driving mechanism includes a motor 25 and a rotating shaft 26, the top of the air guide channel 1 is fixedly connected with a motor 25, the motor 25 is connected to an external power supply, and the output shaft of the motor 25 is fixedly connected with a rotating shaft 26. The rotating shaft 26 is fixedly connected with the transmission rod 4. For the sliding mechanism, the sliding mechanism includes a sliding rail 27 and a sliding block 28. Both sides of the filter screen 3 are provided with sliding rails 27, so The surface of the slide rail 27 is slidably connected with a slide block 28, and the slide block 28 is fixedly connected with the cleaning rod 8. For the air outlet mechanism, the air outlet mechanism includes an air outlet pipe 29 and a one-way valve 2 30. The end of the piston cylinder 12 away from the air inlet pipe 14 is fixedly connected with an air outlet pipe 29, and the end of the air outlet pipe 29 away...

Embodiment 3

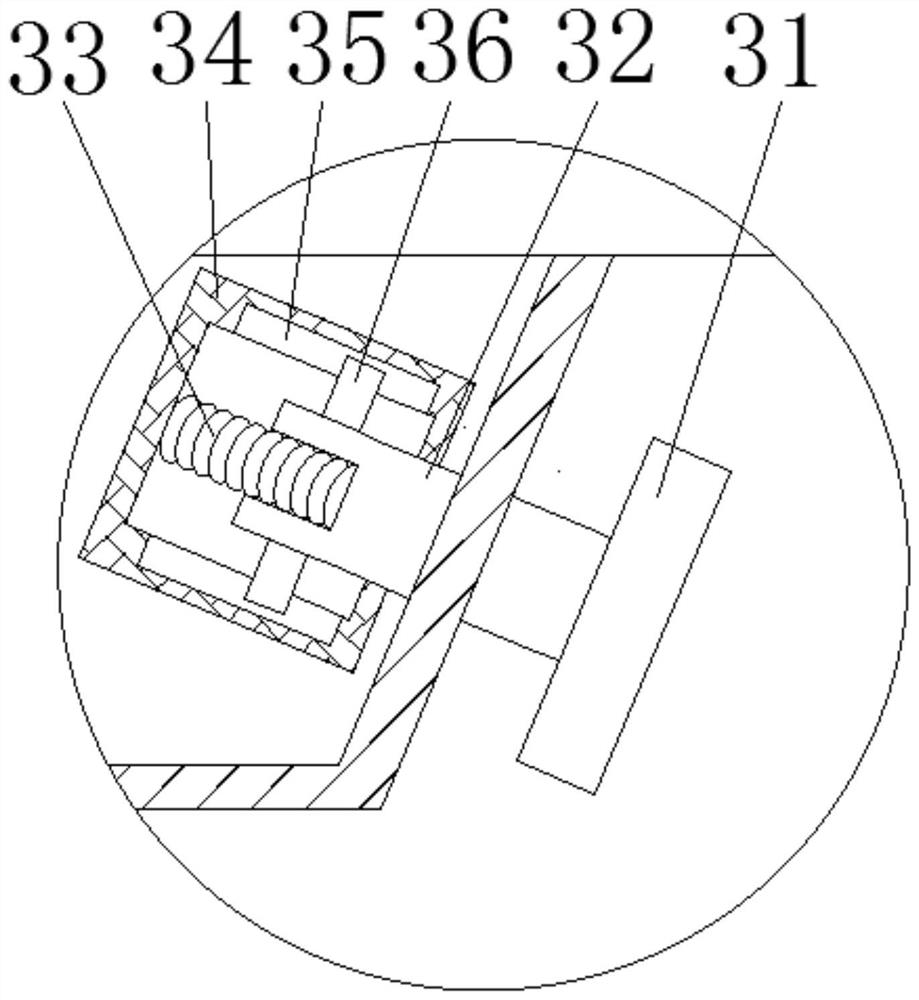

[0037] see Figure 1-5 , for the noise reduction mechanism, the noise reduction mechanism includes a sound baffle 31, a movable block 32, a spring 33 and a fixed cylinder 34, the inside of the protrusion 20 is symmetrically connected with a fixed cylinder 34, and the inside of the fixed cylinder 34 is movable A movable block 32 is connected, one end of the movable block 32 is connected to the inner wall of the fixed cylinder 34 with a spring 33, and the end of the movable block 32 away from the spring 33 passes through the fixed cylinder 34 and is fixedly connected with a sound barrier Plate 31, a limit mechanism is provided between the movable block 32 and the fixed cylinder 34, for the limit mechanism, the limit mechanism includes a limit groove 35 and a limit rod 36, the fixed cylinder 34 Limiting grooves 35 are defined on the inner walls of both sides, and the inside of the limiting grooves 35 is slidably connected with a limiting rod 36 , and the limiting rod 36 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com