Device and method for improving local vacuum degree of pulse wind tunnel

A partial vacuum and wind tunnel technology, which is used in measuring devices, machine/structural component testing, aerodynamic testing, etc. It can solve the problems of large volume space and low evacuation efficiency of vacuum units.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further explained in detail below in conjunction with the accompanying drawings and embodiments.

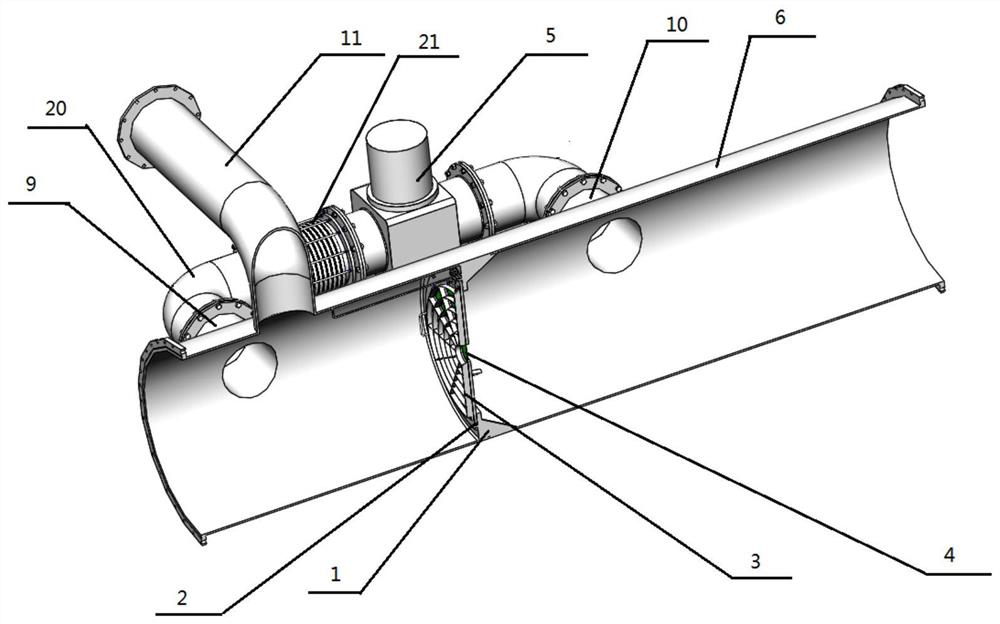

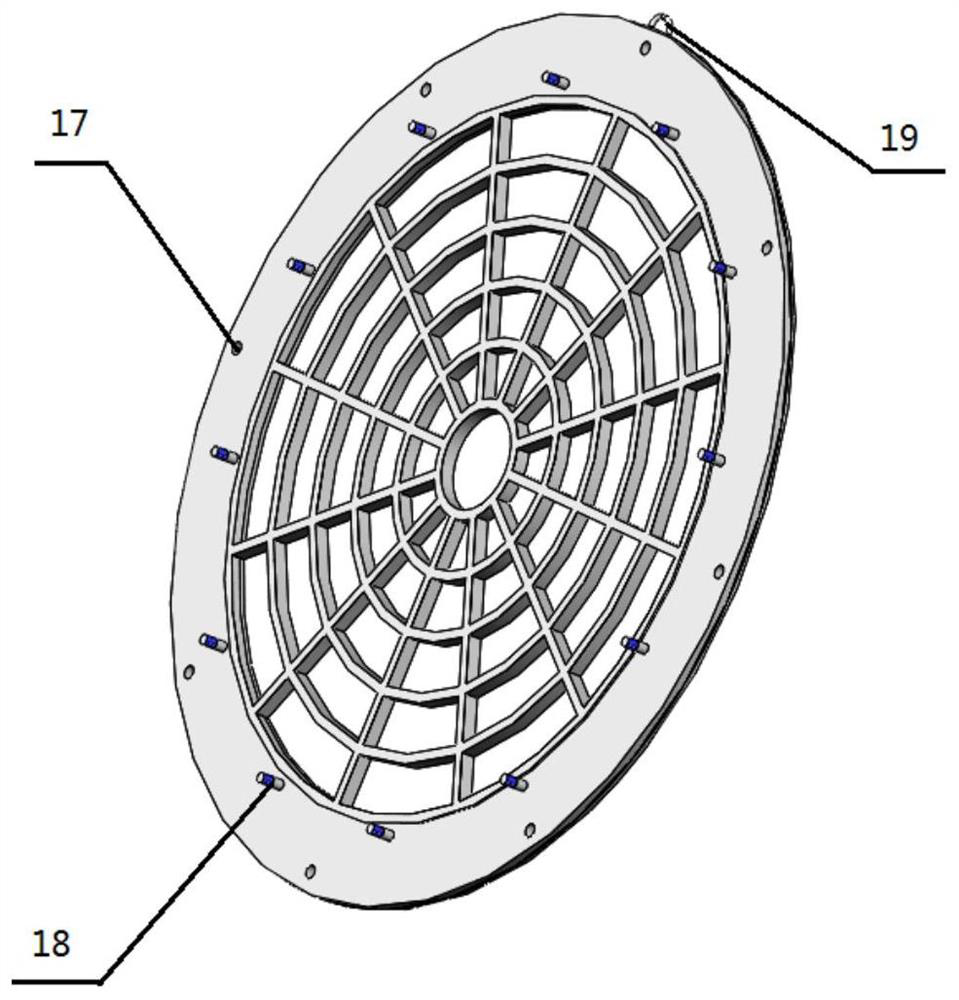

[0038]A device for increasing the local vacuum degree of a pulse wind tunnel, the device comprising: a retaining ring 1, a bottom plate 2, a cover plate 3 and a diaphragm 4;

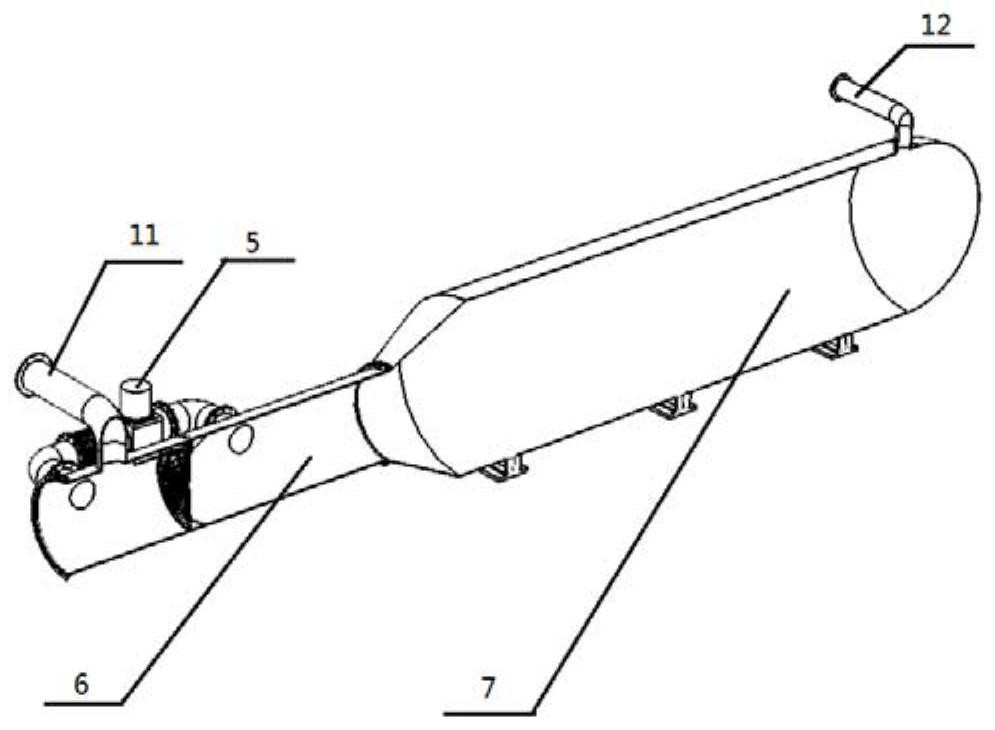

[0039] Among them, the retaining ring 1 is welded on the straight section 6 of the vacuum tube between the wind tunnel test section and the vacuum container device 7. In addition to considering the relatively small volume of the test section after separation, the installation position also needs to ensure that it is within the effective test time. Shock wave emission does not occur, and the upstream and downstream of the position of the retaining ring 1 welded on the straight section 6 of the vacuum tube are respectively welded with a bypass pipe upstream interface 9 and a bypass pipe downstream interface 10, and a bypass valve 5 and corresponding Elbow 20 and bellows 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com