Ultrasonic system

An ultrasonic system and ultrasonic technology, applied in the field of ultrasonic systems, can solve problems such as unsuitability for continuous use, inability to effectively remove material fragments, complex structure, etc., and achieve the effect of great versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

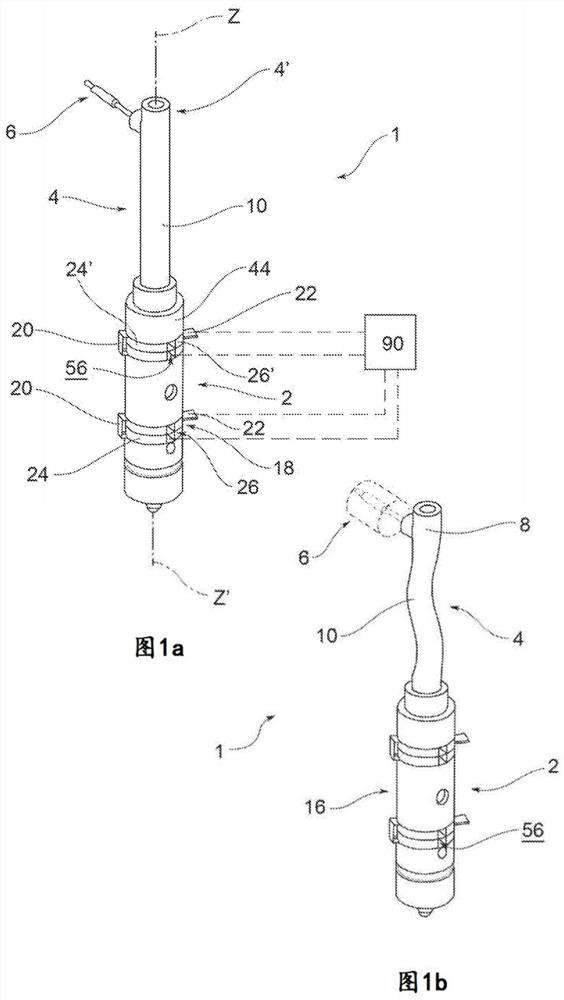

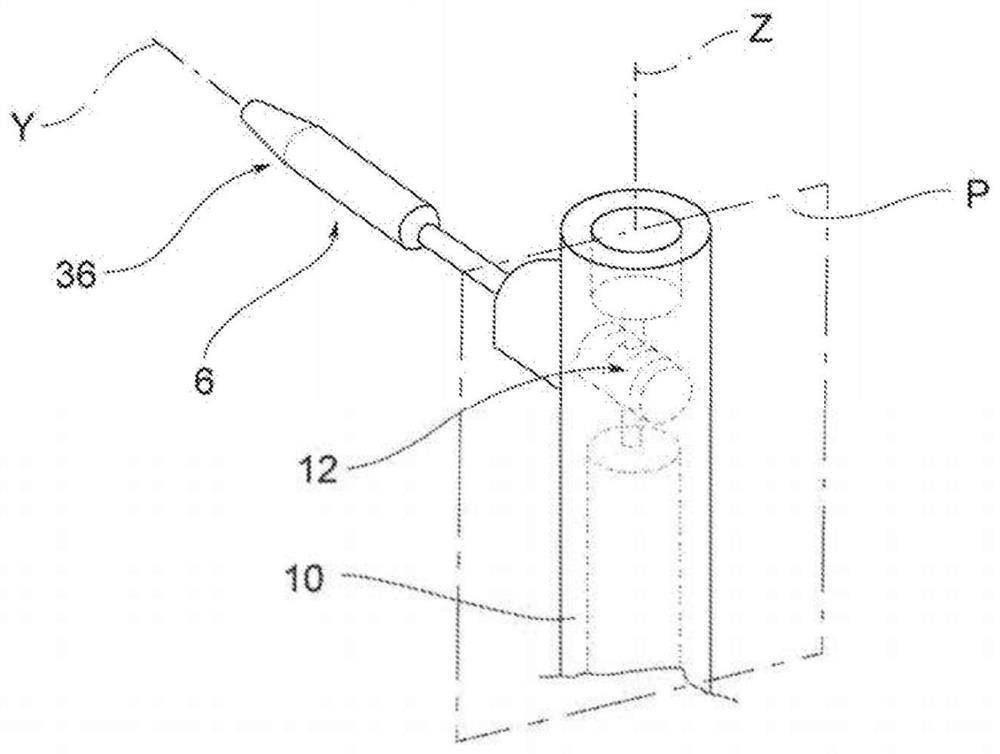

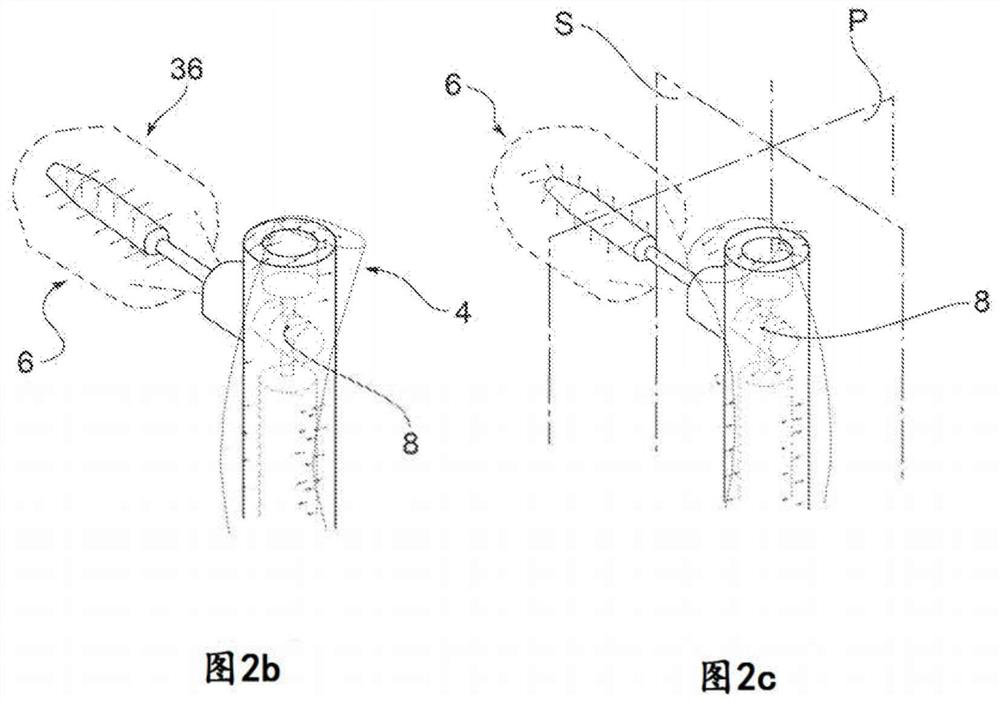

[0056] In the above figures, reference numeral 1 generally designates an ultrasound system 1 comprising an ultrasonic micro-vibration generator device 2 , a waveguide device 4 connected to the generator device 2 and at least one operating element 6 .

[0057] The term "waveguide" refers to a body or part of a body that concentrates and / or amplifies the flexural vibrations of a generator device 2 due to its geometry and position, that is to say also due to its connection to said generator device 2 . part. This component or part of the ultrasound system 1 is also called a "concentrator" because it concentrates (and preferably but not necessarily amplifies) the bending vibrations of the generator device 2, e.g. by reducing its cross-section at least one distal portion thereof. This component or part of the ultrasound system 1 is also referred to as an "ultrasonic horn".

[0058] According to an embodiment, said waveguide 4 is coaxial with said generator device 2 .

[0059] Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com