Efficient rectifying tower for chemical production

A technology for chemical production and rectification towers, applied in the field of rectification towers, can solve the problems affecting the safety of rectification towers, explosion, and the lack of explosion-proof function of high-efficiency rectification towers, so as to reduce low rectification efficiency, improve uniformity, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

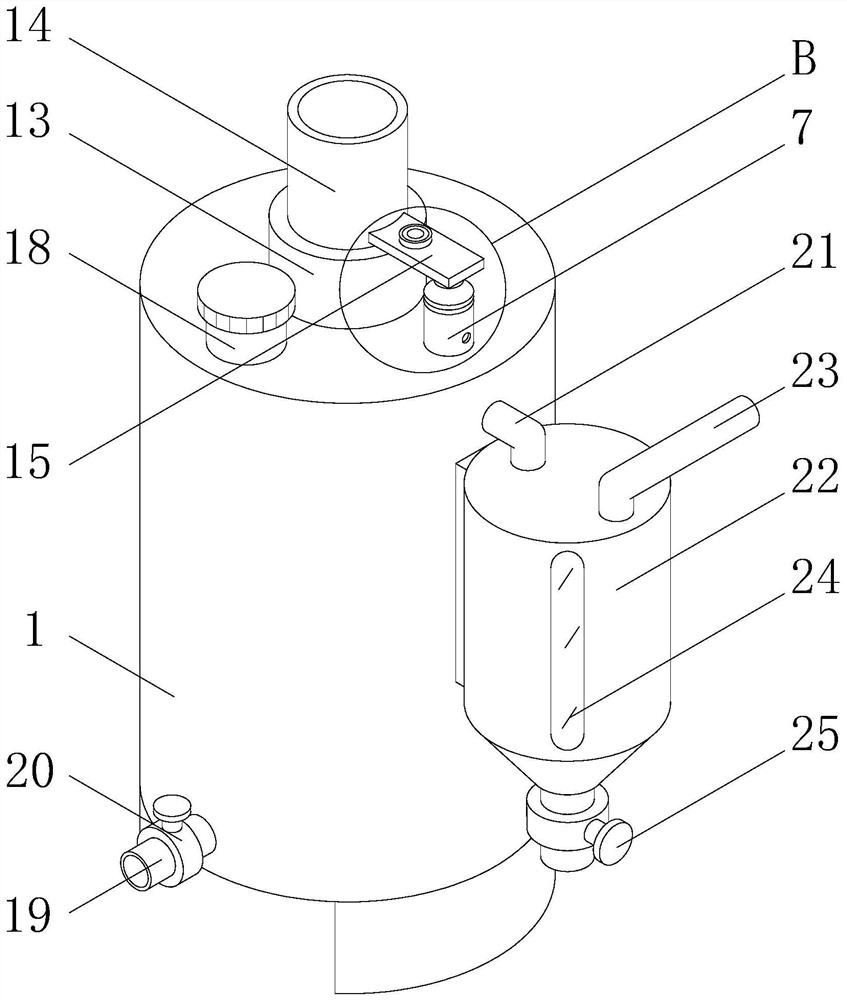

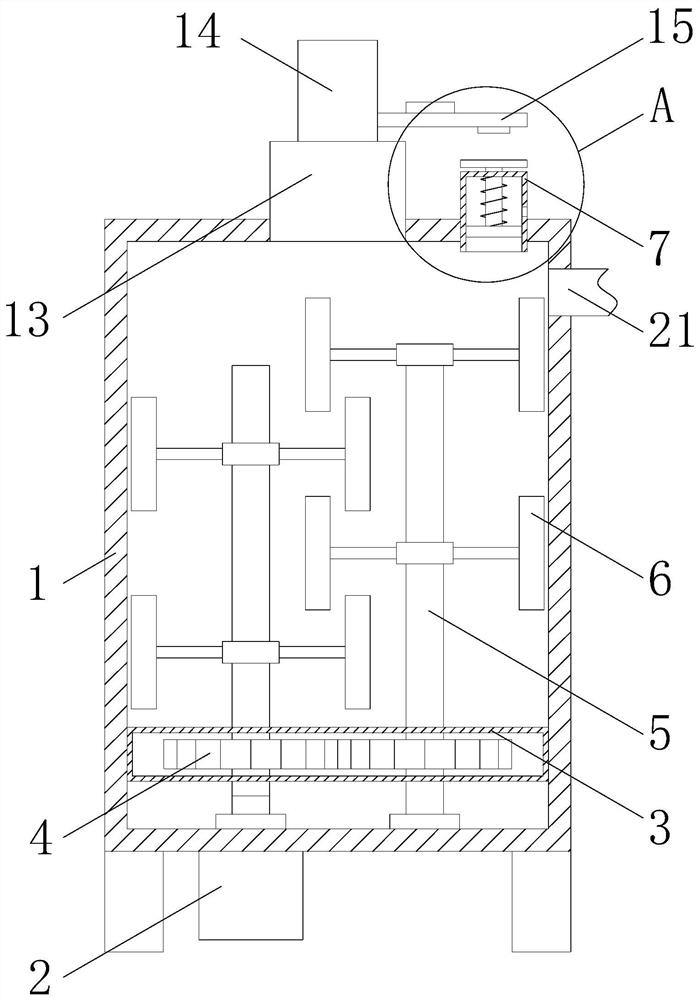

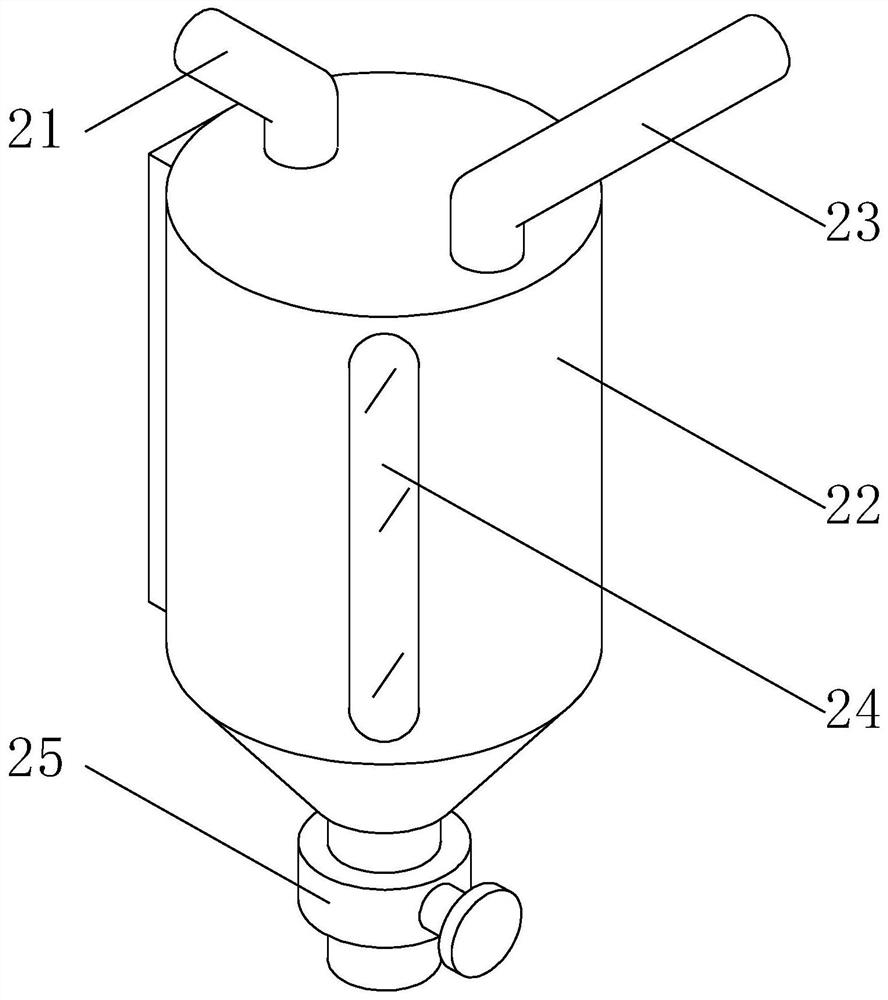

[0028] Example: such as Figure 1-6 As shown, a high-efficiency rectification tower for chemical production of the present invention includes a tower body assembly. The tower body assembly is composed of a tower body 1, a feed pipe 18, a discharge pipe 19 and a first control valve 20. The interior of the tower body 1 is arranged There is a stirring assembly, the stirring assembly is composed of a stepping motor 2, a protective box 3, two transmission gears 4, two rotating shafts 5 and several stirring blades 6, the top of the tower body 1 is provided with a protective assembly, the protective assembly consists of a protective Pipe 7, vent hole 8, connecting rod 9, push plate 10, spring 11, piston 12, solenoid valve 13, exhaust pipe 14, support plate 15, normally open button switch 16 and buzzer 17, the tower body 1 One side is provided with an overflow assembly, and the overflow assembly is composed of a first delivery pipe 21 , a collection tank 22 , a second delivery pipe 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com