Automatic plasma circuit board cleaning machine

A technology for circuit boards and cleaning machines, which is applied in the directions of removing smoke and dust, chemical instruments and methods, cleaning methods and utensils, etc. It can reduce the difficulty of cleaning, avoid displacement, and achieve the effect of high cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

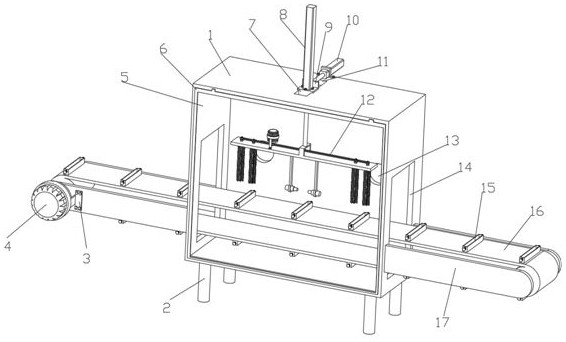

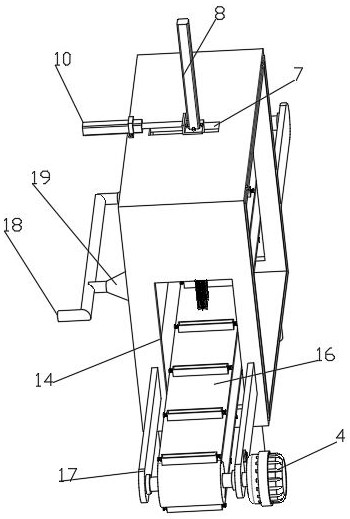

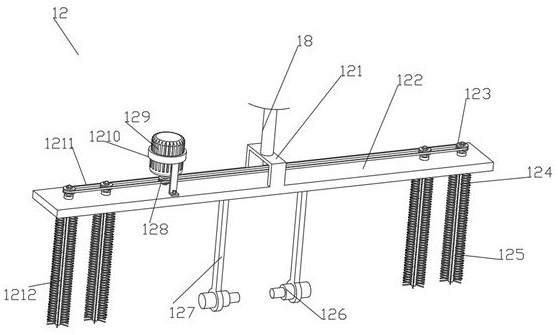

[0032] Such as Figure 1-4 An automatic plasma circuit board cleaning machine is shown, including a cleaning box 1, a drive motor 4, a first electric push rod 8 and a second electric push rod 10, the bottom of the cleaning box 1 is symmetrically fixedly connected with a leg 2, and the cleaning box 1 The left and right side walls of the support plate 17 are symmetrically fixedly connected with a support plate 17, the front side wall of the support plate 17 is fixedly connected with a mounting plate 3 by bolts, the mounting plate 3 is fixedly connected with a drive motor 4, and the inner wall of the support plate 17 is rotatably connected by a fixedly connected bearing. There is a conveyor belt 16, the rotating shaft of the conveyor belt 16 is fixedly connected to the output end of the drive motor 4, the outer wall of the conveyor belt 16 is uniformly fixedly connected with a fixed structure 15 for fixing the circuit board, and the top of the cleaning box 1 is fixedly connected w...

Embodiment 2

[0035] Embodiment 2 is a further improvement to Embodiment 1.

[0036] Such as Figure 1-4 A kind of automatic plasma circuit board cleaning machine shown, comprises cleaning box 1, driving motor 4, first electric push rod 8 and second electric push rod 10, and the front side wall of cleaning box 1 is rotatably connected with Door panel 6, the through hole of door panel 6 is fixedly connected with a glass window 5 for easy observation, and the cleaning box 1 is connected to the door panel 6 through a hinge, so that the door panel 6 is convenient to open, and the parts in the cleaning box 1 are conveniently cleaned, and at the same time, it is fixed in the door panel 6 Glass window 5, convenient to observe the cleaning situation of the cable board;

[0037] The bottom of the cleaning box 1 is symmetrically and fixedly connected with supporting legs 2, and the left and right side walls of the cleaning box 1 are symmetrically and fixedly connected with a support plate 17, and th...

Embodiment 3

[0039] Embodiment 3 is a further improvement to Embodiment 1.

[0040] Such as Figure 1-4 The shown automatic plasma circuit board cleaning machine includes a cleaning box 1, a drive motor 4, a first electric push rod 8 and a second electric push rod 10, the bottom of the cleaning box 1 is symmetrically fixedly connected with a leg 2, and the cleaning box The left and right side walls of 1 are symmetrically fixedly connected with a support plate 17, and the inner wall of the support plate 17 is rotatably connected with a conveyor belt 16 through a fixedly connected bearing. A fixed structure 15 for fixing the circuit board is connected, the top of the cleaning box 1 is fixedly connected with a second electric push rod 10, the telescopic end of the second electric push rod 10 is fixedly connected with a straight plate 9, and the straight plate 9 is fixedly connected with a T-shaped slider 7. The first electric push rod 8 is fixedly installed on the T-shaped slider 7, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com