Mechanical part machining device in mechanical field

A technology of mechanical parts and processing devices, which is applied in the field of parts processing, can solve problems such as troublesome, no clamping device, and dangerous cutting process, and achieve the effects of reducing labor intensity, reducing repetitive labor, and improving friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

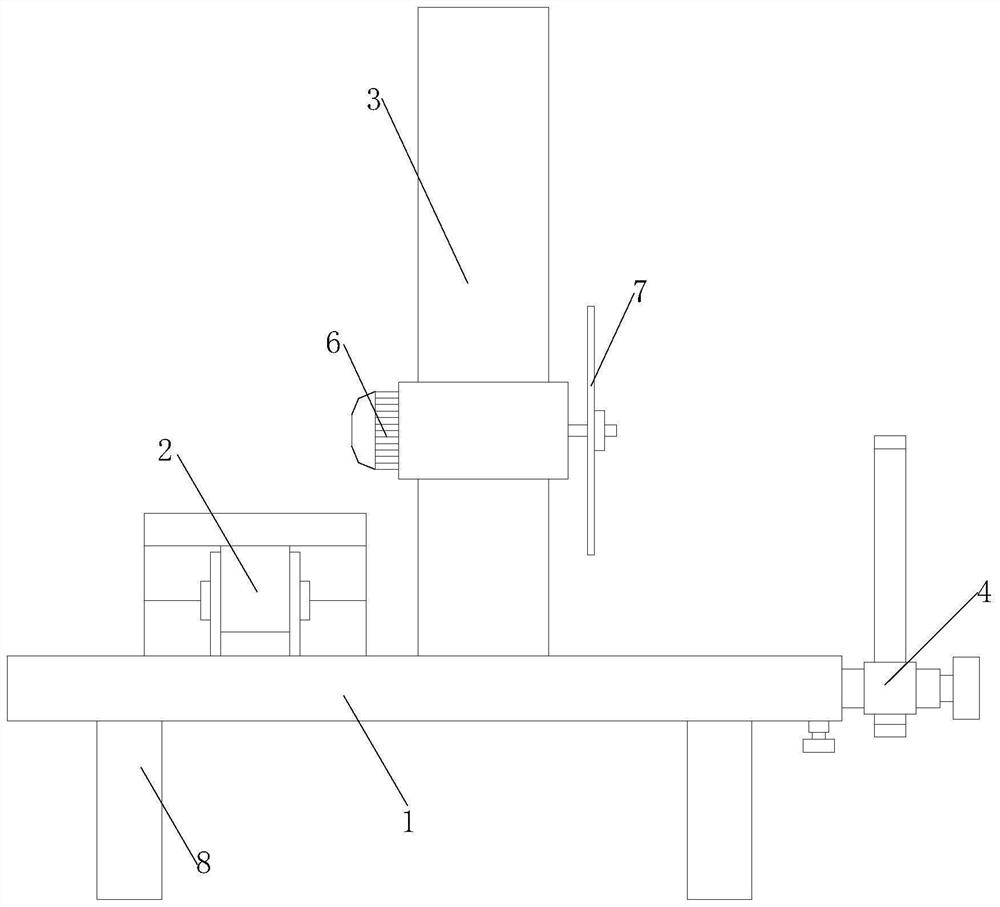

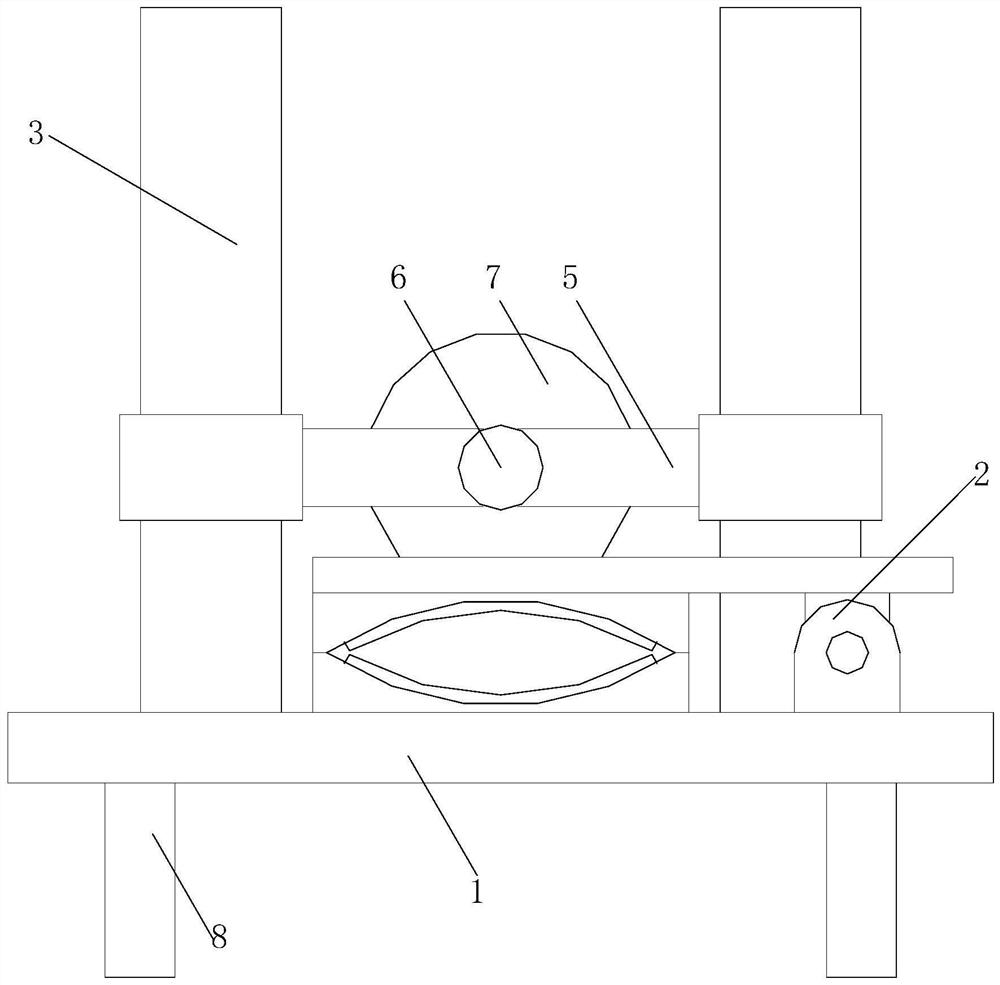

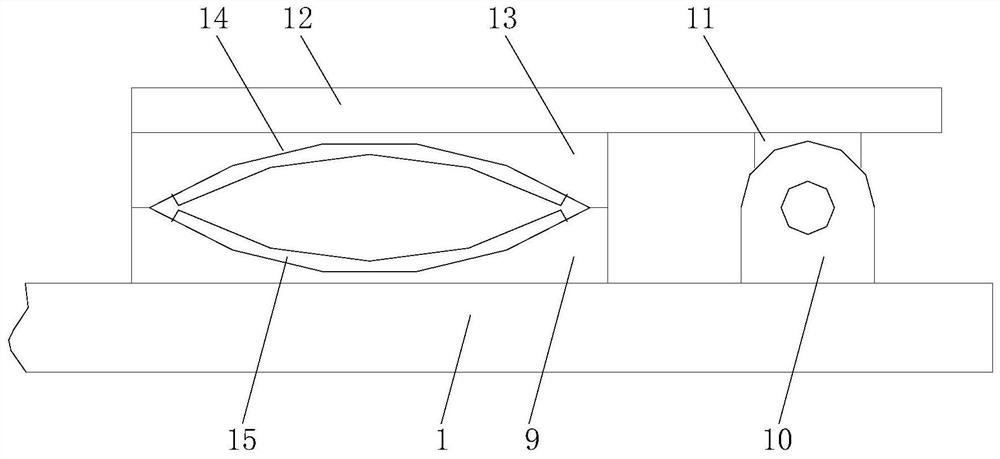

[0028] Such as Figure 1-5 As shown, the present invention provides a kind of technical scheme:

[0029] A processing device for mechanical parts in the mechanical field, comprising a console 1, a support foot 8 is fixedly installed on the bottom of the console 1, the support foot 8 has a shock-absorbing function, the bottom of the support foot 8 is provided with a shock-absorbing rubber pad, and has a shock-absorbing rubber pad. The supporting foot 8 with vibration function can reduce the damage caused by vibration to the equipment. At the same time, the rubber pad at the bottom of the supporting foot 8 can move the textile equipment very well. Two sets of identical mechanisms are arranged symmetrically, and two sets of lifting mechanisms 3 are respectively arranged at both ends of the motor cross arm 5, and the two lifting mechanisms 3 cooperate with each other so that the entire motor cross arm 5 can move up and down smoothly.

[0030] The lifting mechanism 3 includes a li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com