Production process for copper casting sleeve of bearing

A production process and copper casting technology, applied in the field of bearing production, can solve problems such as affecting machine work, reducing bearing life, loud noise, etc., to eliminate unqualified quality, improve strength, and simplify processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

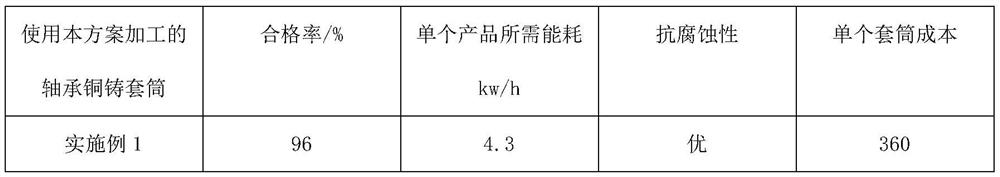

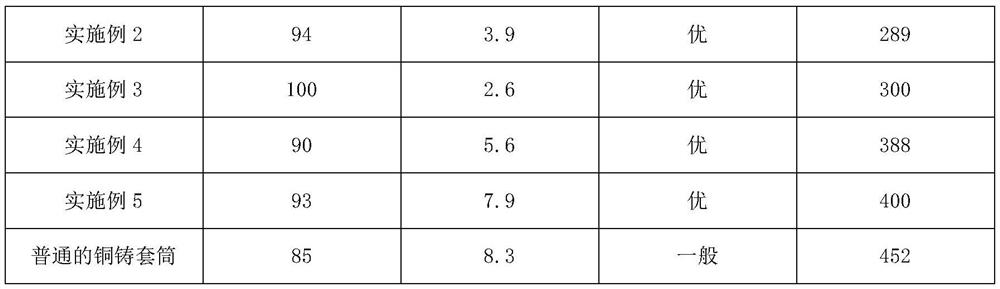

Examples

Embodiment 1

[0025] A production process of a bearing copper casting sleeve, comprising the following steps:

[0026] S1. Blank inspection: the non-destructive testing equipment for steel rods sorts copper materials, eddy current flaw detection for surface cracks, ultrasonic internal defect detection, automatically paints and marks the parts of steel rods that do not meet the inspection requirements, and scraps the defective parts;

[0027] S2. Rough boring inner hole: fix the qualified copper material on the lathe, and use the special inner hole boring tool to open holes on the qualified copper material;

[0028] S3. Rough turning outer circle: rough turning the outer circle of copper material, using polycrystalline diamond turning tool to rough turn the outer circle of copper material, after rough turning, the wall thickness of the pipe is reduced by 0.5mm, and rough material A is obtained;

[0029] S4, heat treatment: Put the crude material A obtained in step S3 into a heat treatment fu...

Embodiment 2

[0034] A production process of a bearing copper casting sleeve, comprising the following steps:

[0035] S1. Blank inspection: the non-destructive testing equipment for steel rods sorts copper materials, eddy current flaw detection for surface cracks, ultrasonic internal defect detection, automatically paints and marks the parts of steel rods that do not meet the inspection requirements, and scraps the defective parts;

[0036] S2. Rough boring inner hole: fix the qualified copper material on the lathe, and use the special inner hole boring tool to open holes on the qualified copper material;

[0037] S3. Rough turning outer circle: rough turning the outer circle of copper material, using polycrystalline diamond turning tool to rough turn the outer circle of copper material, after rough turning, the wall thickness of the pipe material is reduced by 0.7mm, and rough material A is obtained;

[0038] S4, heat treatment: Put the crude material A obtained in step S3 into a heat tre...

Embodiment 3

[0043] A production process of a bearing copper casting sleeve, comprising the following steps:

[0044] S1. Blank inspection: the non-destructive testing equipment for steel rods sorts copper materials, eddy current flaw detection for surface cracks, ultrasonic internal defect detection, automatically paints and marks the parts of steel rods that do not meet the inspection requirements, and scraps the defective parts;

[0045] S2. Rough boring inner hole: fix the qualified copper material on the lathe, and use the special inner hole boring tool to open holes on the qualified copper material;

[0046] S3. Rough turning outer circle: rough turning the outer circle of copper material, using polycrystalline diamond turning tool to rough turn the outer circle of copper material, after rough turning, the wall thickness of the pipe material is reduced by 0.7mm, and rough material A is obtained;

[0047] S4, heat treatment: Put the crude material A obtained in step S3 into a heat tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com