Lightweight truck aluminum hub

A lightweight, truck technology, applied in the direction of wheels, wheel manufacturing, highly elastic wheels, etc., can solve the problems of high driving noise and variability, and achieve the effects of reducing noise, improving service life, and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

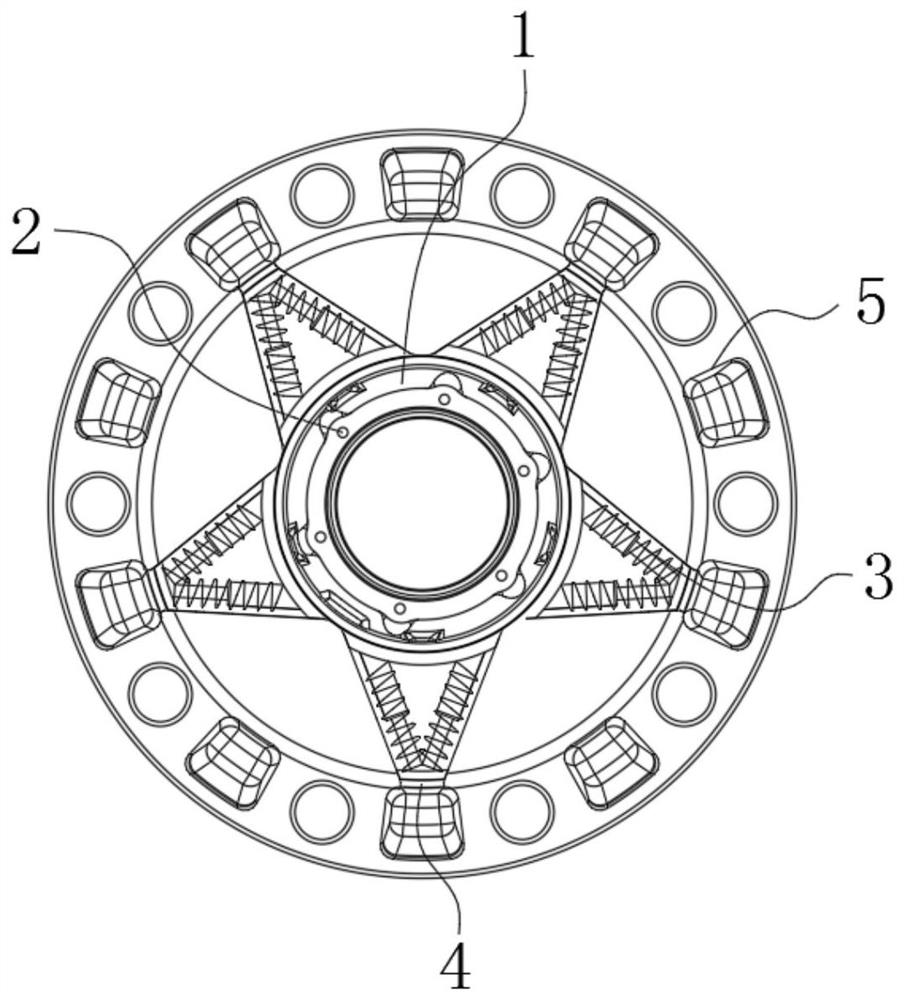

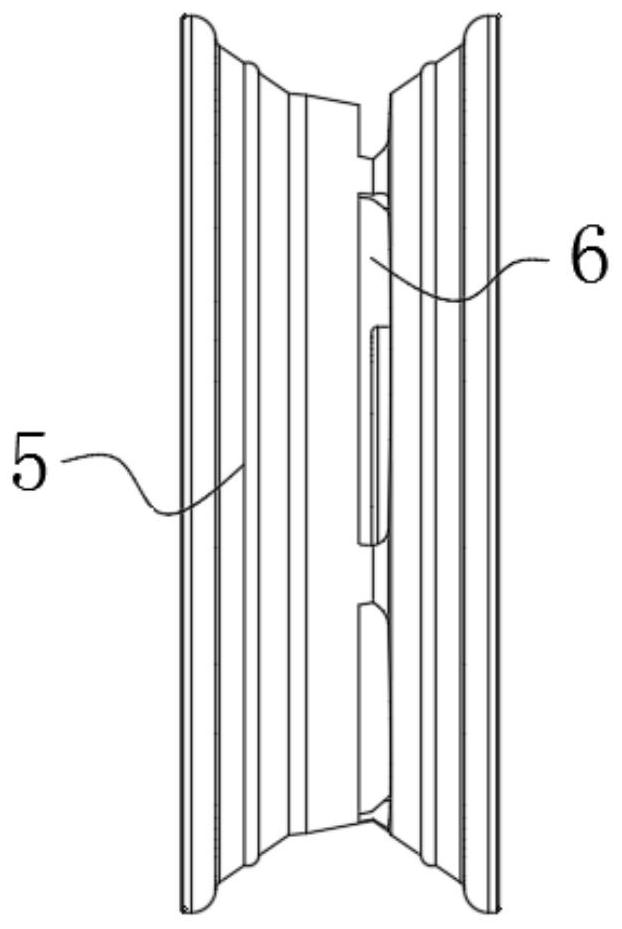

[0029] Embodiment 1: by Figure 1-4 Given, the present invention provides the following technical solution: a light-weight truck aluminum wheel hub, including a hub 1, the outer wall of the hub 1 is fixed on the positioning seat 4 on the inner wall of the rim 5 through the spokes 3, and the five spokes 3 are five-star shape distribution;

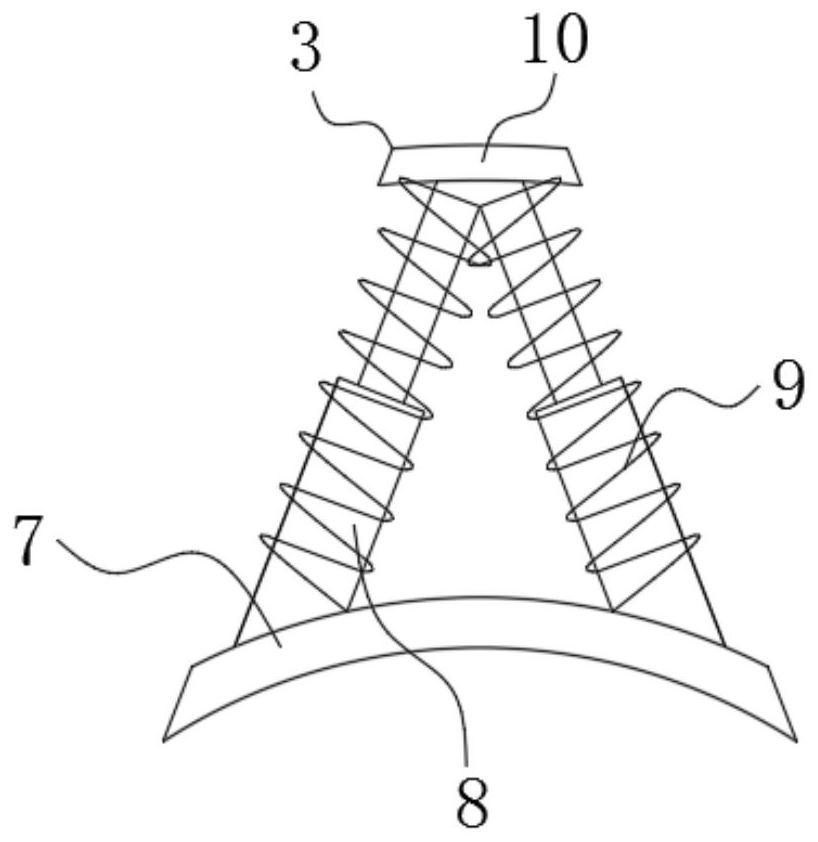

[0030] The spoke 3 comprises a lower base 7, a telescopic assembly 8, a first support spring 9 and an upper base 10, the lower base 7 is fixed around the outer wall of the axle sleeve 1, and the top of the lower base 7 is fixed with an upper base 10 by two telescopic assemblies 8, The two telescopic assemblies 8 are distributed in an inverted V shape, the upper base 10 is fixed on the positioning seat 4 , and the telescopic assembly 8 is sleeved with a first support spring 9 located between the lower base 7 and the upper base 10 .

[0031] According to the above technical solution, the telescopic assembly 8 includes an externally threaded s...

Embodiment 2

[0044] Embodiment 2: by Figure 1-4 Given, the present invention provides the following technical solution: a light-weight truck aluminum wheel hub, including a hub 1, the outer wall of the hub 1 is fixed on the positioning seat 4 on the inner wall of the rim 5 through the spokes 3, and the five spokes 3 are five-star shape distribution;

[0045] The spoke 3 comprises a lower base 7, a telescopic assembly 8, a first support spring 9 and an upper base 10, the lower base 7 is fixed around the outer wall of the axle sleeve 1, and the top of the lower base 7 is fixed with an upper base 10 by two telescopic assemblies 8, The two telescopic assemblies 8 are distributed in an inverted V shape, the upper base 10 is fixed on the positioning seat 4 , and the telescopic assembly 8 is sleeved with a first support spring 9 located between the lower base 7 and the upper base 10 .

[0046] According to the above technical solution, the telescopic assembly 8 includes an externally threaded sle...

experiment example

[0060] Experimental object: the shaft sleeve aluminum alloy block prepared in the embodiment of the present invention was used as the experimental group 1, the experimental group 2 and the experimental group 3, and the aluminum alloy block of ordinary quality on the market was selected as the comparative group 1.

[0061] Experimental purpose: To test the tensile strength, yield strength and elongation of each group of aluminum alloy blocks.

[0062] Experiment method: According to GB / T 4340.1:2009 and ISO 6507-1:2005, XL-250A tensile testing machine is used for testing, and professional instruments are used to test the tensile strength, yield strength and elongation of each group of aluminum alloy blocks. Test and record the results of the experiment.

[0063] Experimental result table:

[0064]

[0065] The shaft sleeve formed from aluminum alloy used in the present invention has significantly higher tensile strength, yield strength and elongation than the shaft sleeve f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com