Method for automatically storing and taking pipe fittings and bin-dividing type material frame

A material rack and sub-silo technology, applied in the field of pipe fittings processing equipment, can solve the problems of product pollution, low efficiency and high production cost, and achieve the effect of high degree of automation, reduction of labor cost and labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following description serves to disclose the present invention to enable those skilled in the relevant art to carry out the present invention. The embodiments in the following description are only examples, and those skilled in the relevant art can conceive of other obvious modifications that fall within the protection scope of the present invention.

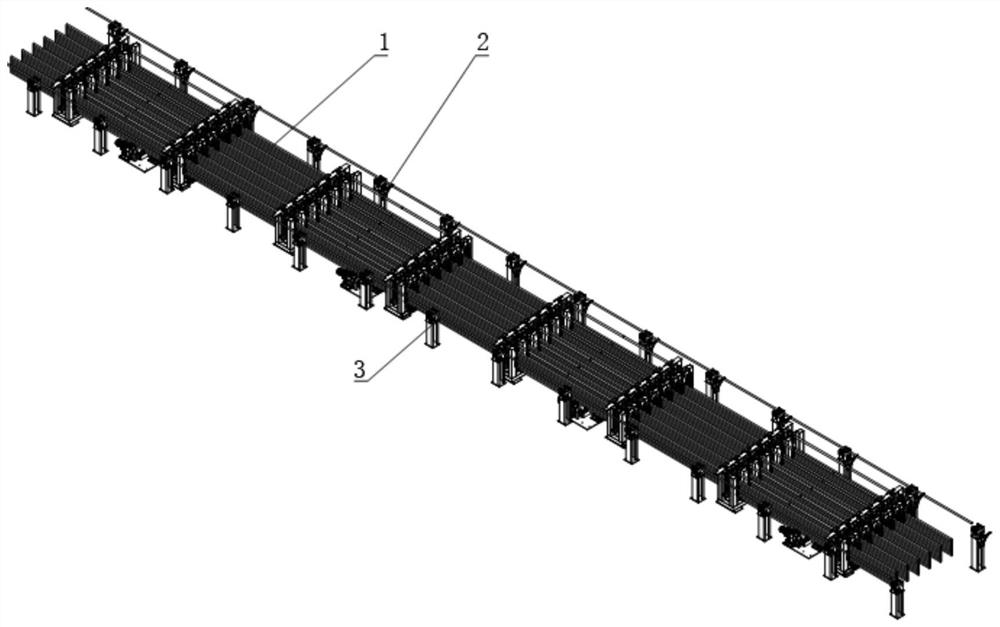

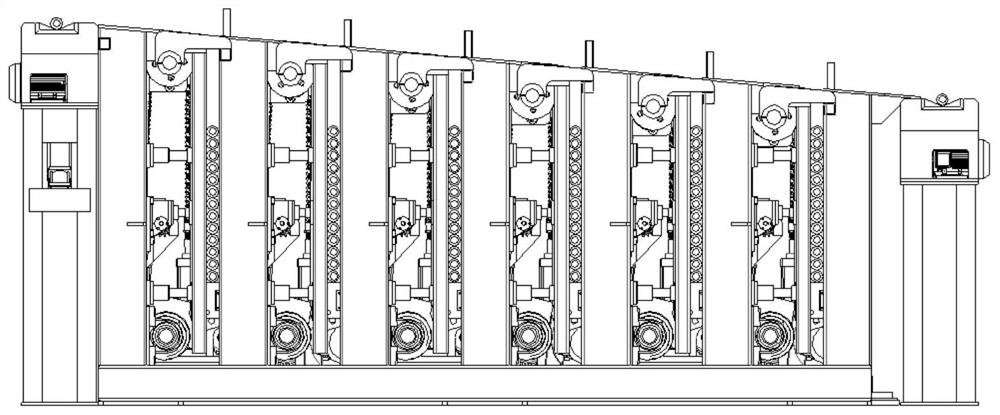

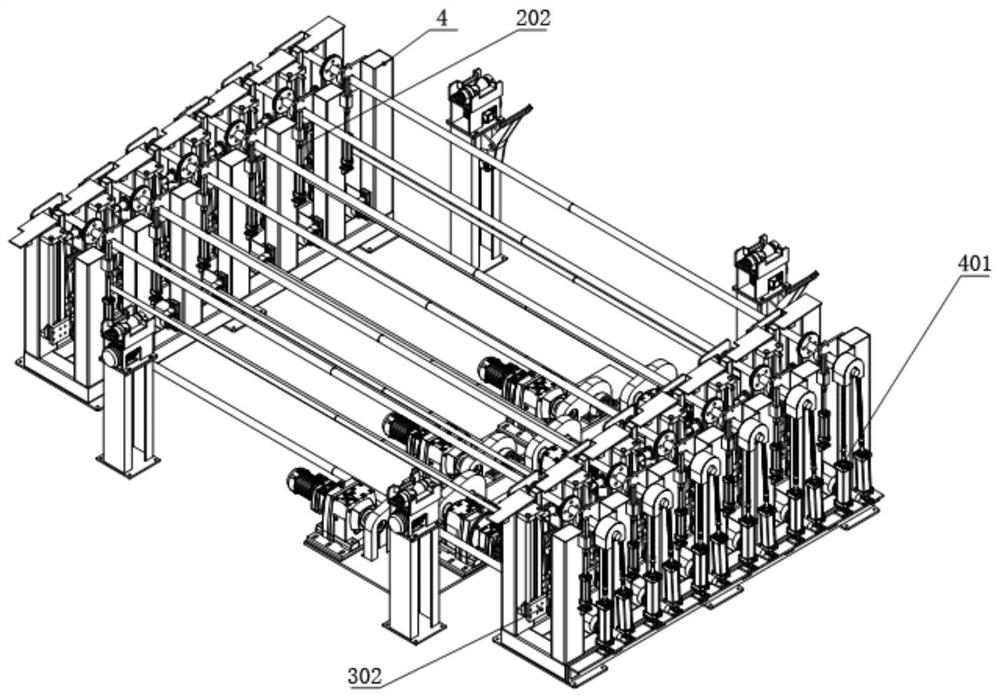

[0032] Attached below Figure 1-9 And embodiment, scheme of the present invention is further described.

[0033] In the boiler industry, after the pipe fittings are lengthened, they are conveyed to the material rack through the feed roller table, and then transferred to the discharge roller table for bending and other processing. The invention provides a sub-compartment material rack. Through a preset program, the pipe fittings automatically enter the corresponding compartments of the sub-compartment type material rack to realize automatic feeding; when taking materials, open the compartment of the corresponding spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com