GMP workshop intelligent monitoring management system

A monitoring management and management system technology, applied in the energy industry, comprehensive factory control, electrical program control, etc., can solve the problems of not being able to detect violations of production personnel in time, poor intelligence, and not being able to control the workshop environment in real time. The effect of reducing energy consumption, increasing production costs, and avoiding false alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

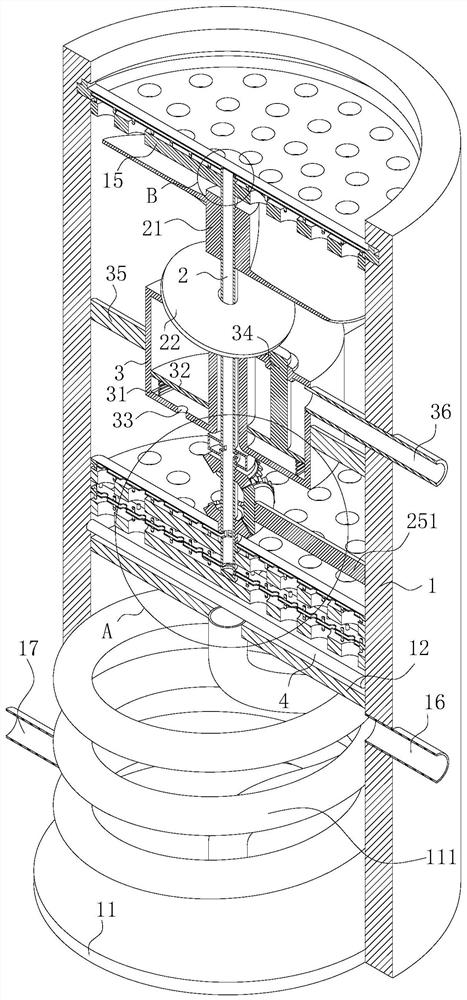

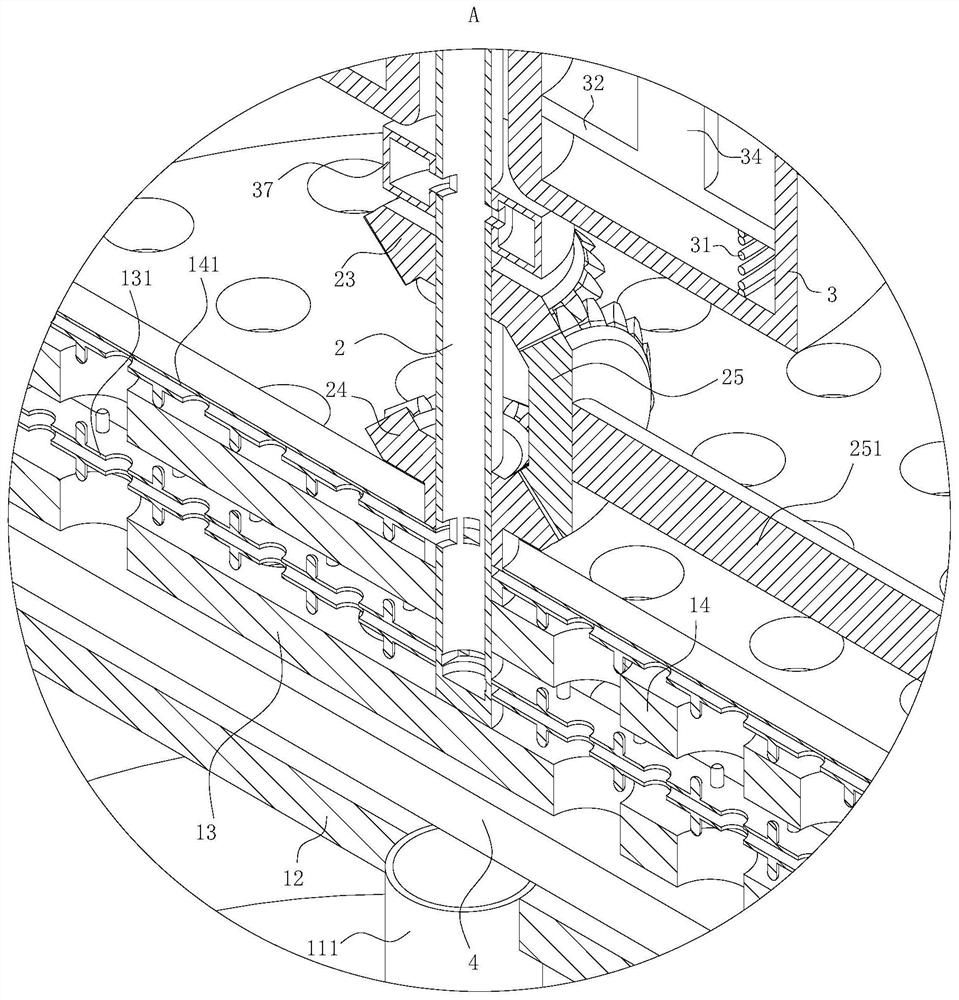

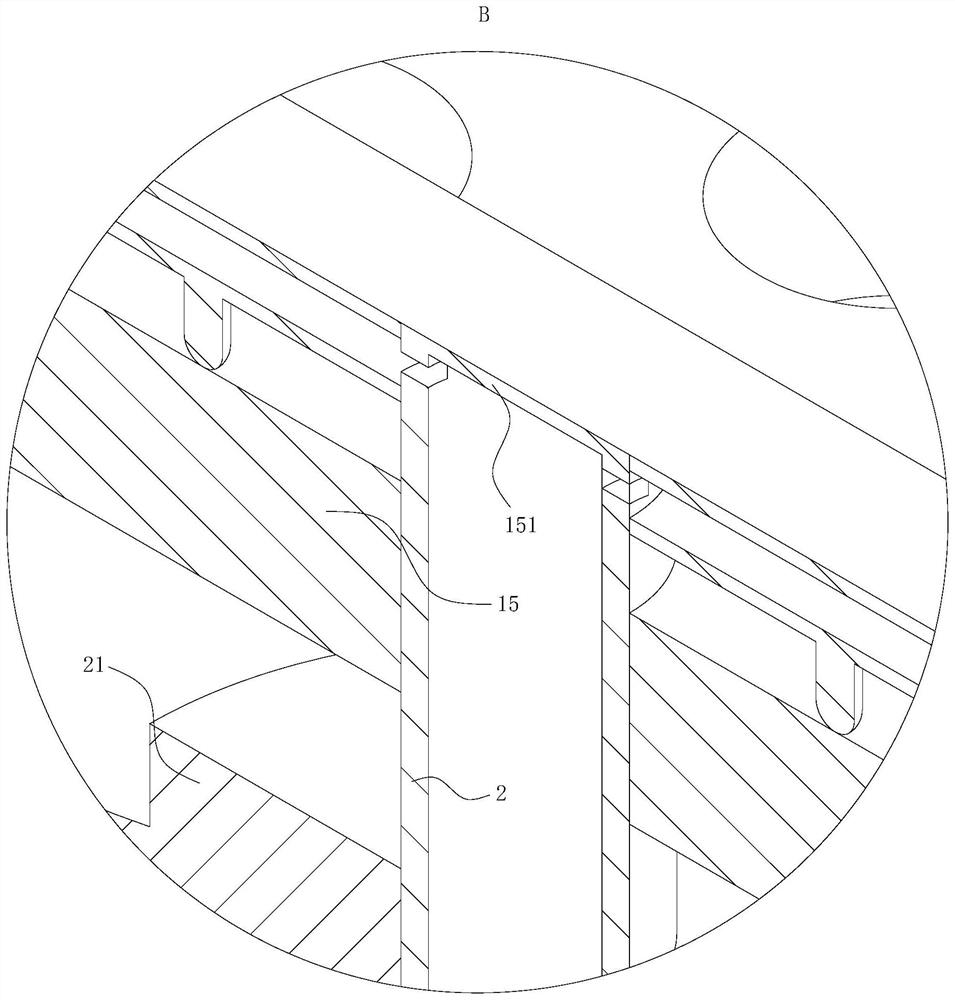

[0040]As an embodiment of the present invention, the dust removal and ventilation device includes a main body; the first filter plate 13, the second filter plate 14 and the third filter plate 15 are sequentially installed in the main body from bottom to top; the first filter plate 13, the filter plate The second 14 and the filter plate three 15 do not contact each other; the mesh diameter on the filter plate three 15 is the largest, the mesh diameter on the filter plate one 13 is the smallest, and the mesh diameter on the filter plate two 14 is between the filter plate Between one 13 and filter plate three 15 upper hole diameters; said main body is equipped with an air extractor 3, and the air extractor 3 is positioned between filter plate two 14 and filter plate three 15; fixed on the side wall of said air extractor 3 A plurality of fixed columns 35 are installed; the other end of the fixed column 35 is fixedly mounted on the inner wall of the main body; the center line of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com