Rape stalk pre-cutting device

A pre-cutting and stalk technology, which is applied in the agricultural field, can solve the problems of messy stalks, unfavorable recycling of straws, unfavorable recycling and use, etc., and achieve the effect of improving safety, easy cutting, and stable lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

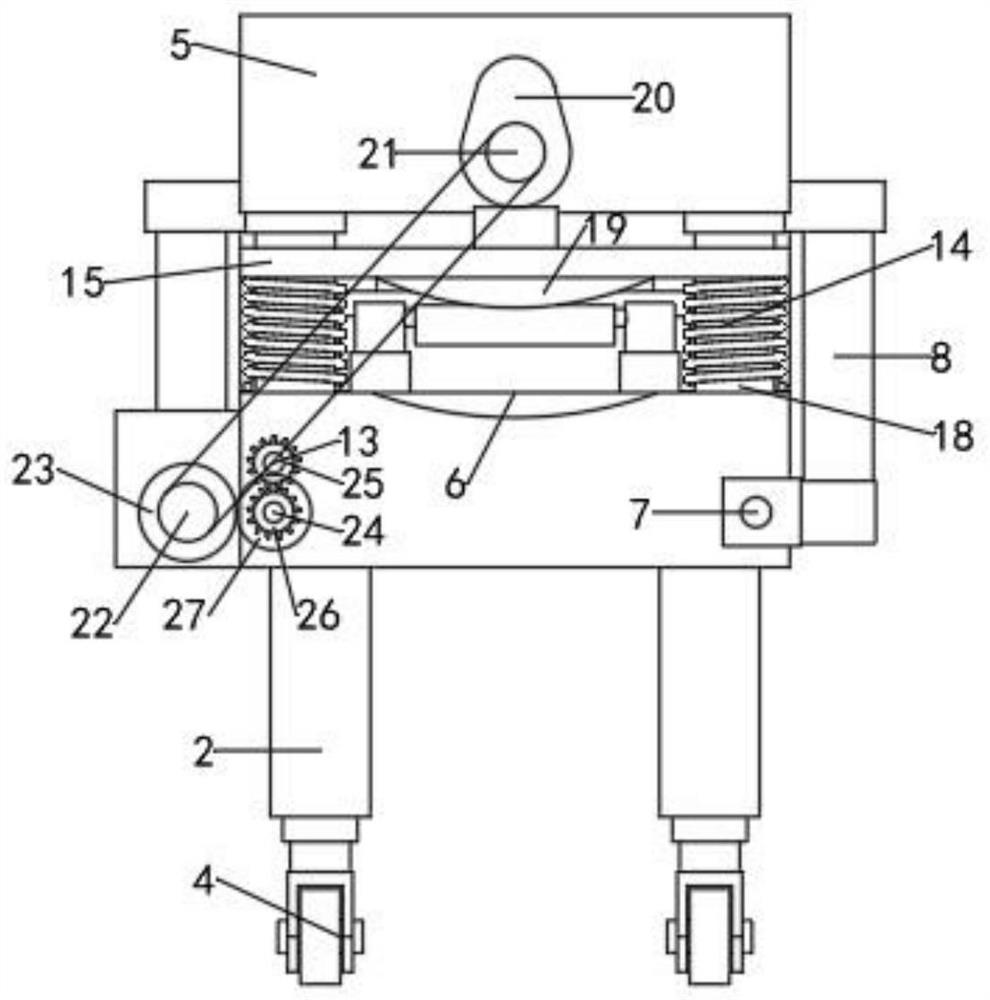

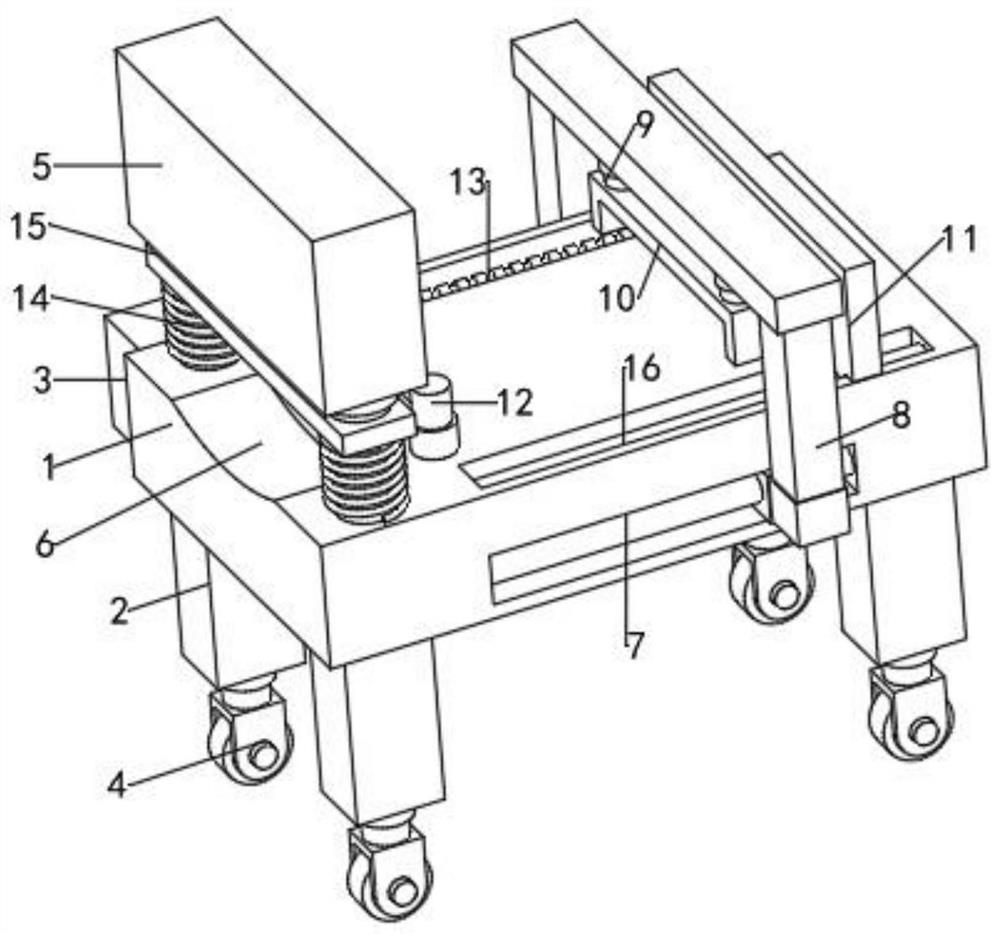

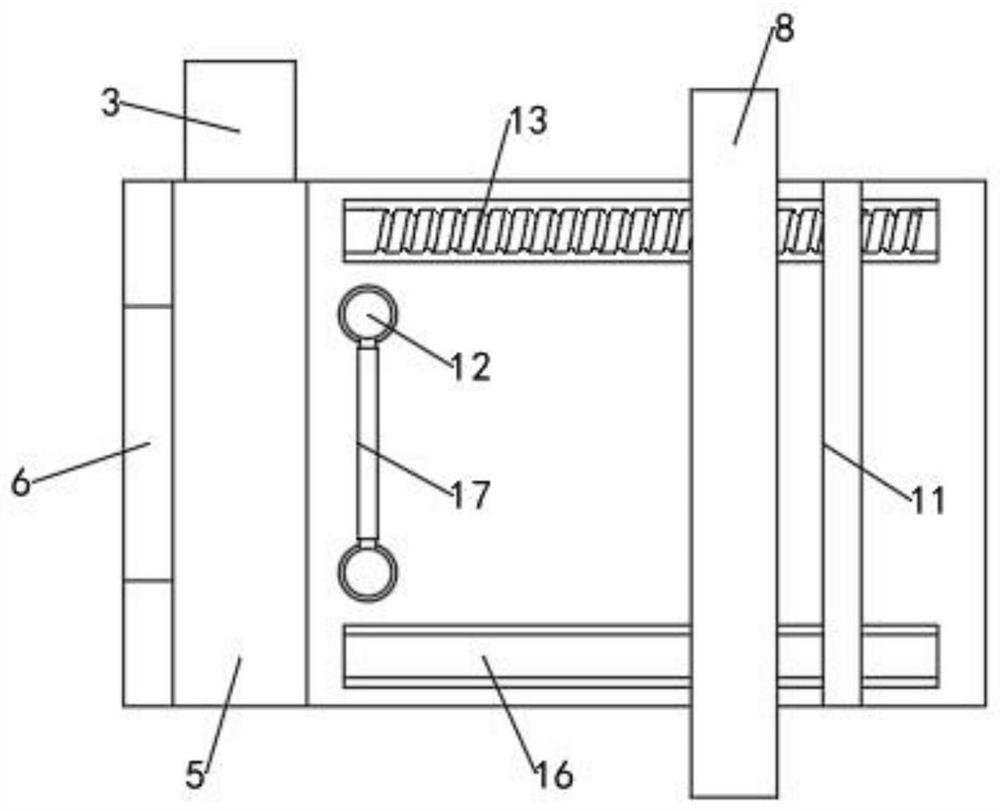

[0020] see Figure 1-4 , a device for pre-cutting rape stalks, comprising a workbench 1, the lower end of the workbench 1 is evenly equipped with several vertical support legs 2, and the upper end of the workbench 1 is equipped with a cutting mechanism and a feeding mechanism linked to each other, To realize equidistant pre-cutting of rape stalks, the cutting mechanism includes a transmission chamber 5, a drive chamber 3 is fixedly connected to one side of the workbench 1, and two vertical The assembly rod 18, the section of the assembly rod 18 is T-shaped, the periphery of the assembly rod 18 is equipped with a return spring 14, the upper end of the two assembly rods 18 is equipped with a transmission chamber 5, and a cam 20 is installed in the transmission chamber 5, and the two assemblies A slide seat 15 is slid between the rods 18, the upper end of the slide seat 15 is connected to the cam 20 through transmission, the lower end of the slide seat 15 is equipped with a cutti...

Embodiment 2

[0029] In order to reduce the jolting of the pre-cutting device when moving, this embodiment is improved on the basis of Embodiment 1. The improvement is: one end of the assembly seat extends to the inside of the support leg 2 and is connected to the support leg 2. A shock-absorbing spring is installed between them, so as to reduce the bump when the pre-cutting device moves and facilitate operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com