Clamshell type whole grain rice sieve

A whole-grain, clamshell-style technology, which is applied in the fields of grain finishing, grain husking, and grain processing, and can solve problems such as easy breakage, broken rice, and nothing left.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

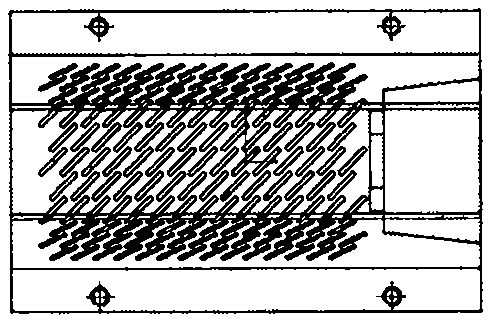

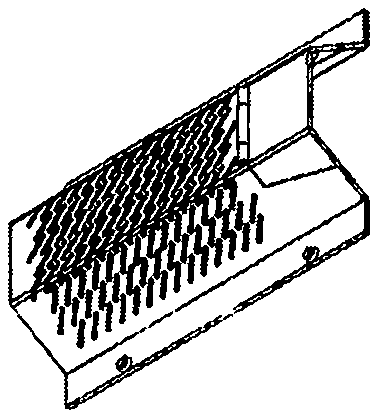

[0018] The hexagonal rice sieve is a two-lobed structure, and the center side is fixed with screws.

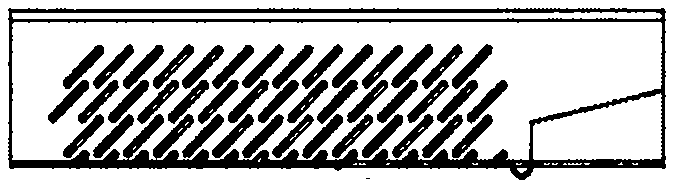

[0019] 40-55% of the inner wall surface of the hexagonal rice sieve is file tooth pattern from coarse to fine, from deep to shallow, which strengthens grinding and roughening.

[0020] The middle 35-45% is a flat surface, which is convenient for the grain to roll and frictionally polish itself.

[0021] The lower 15-20% is equipped with symmetrical or semi-open hinges to control the whitening pressure and rice output speed.

[0022] The 1 / 2 of both sides of the hinge is equipped with 300% high-strength food-grade silica gel, which plays the role of rebound closure.

[0023] The bottom of the hinge is connected to the static friction double-acting cylinder.

[0024] Choose 201#, 304# stainless steel plate, thickness 1.2-1.5mm, punch 15×1.5 long strip holes.

[0025] The gear chopping machine chops out the tooth pattern from thick to fine and from deep to shallow in turn.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com