Feed production cleaning device and application method thereof

A cleaning device and feed technology, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of incompleteness, time-consuming and labor-intensive, low efficiency, etc., achieve the convenience of dumping and adding, and improve cleaning effect, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

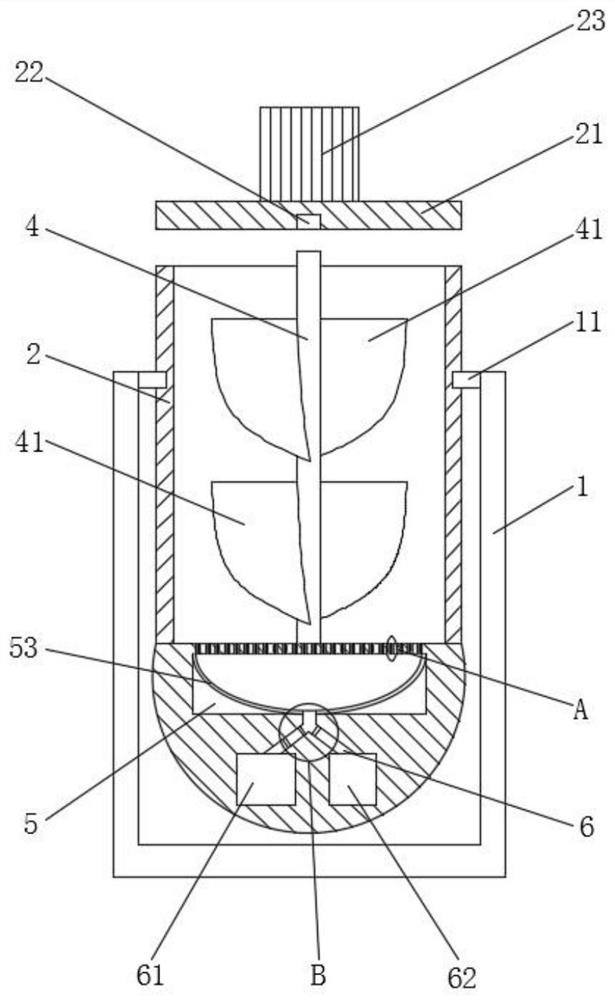

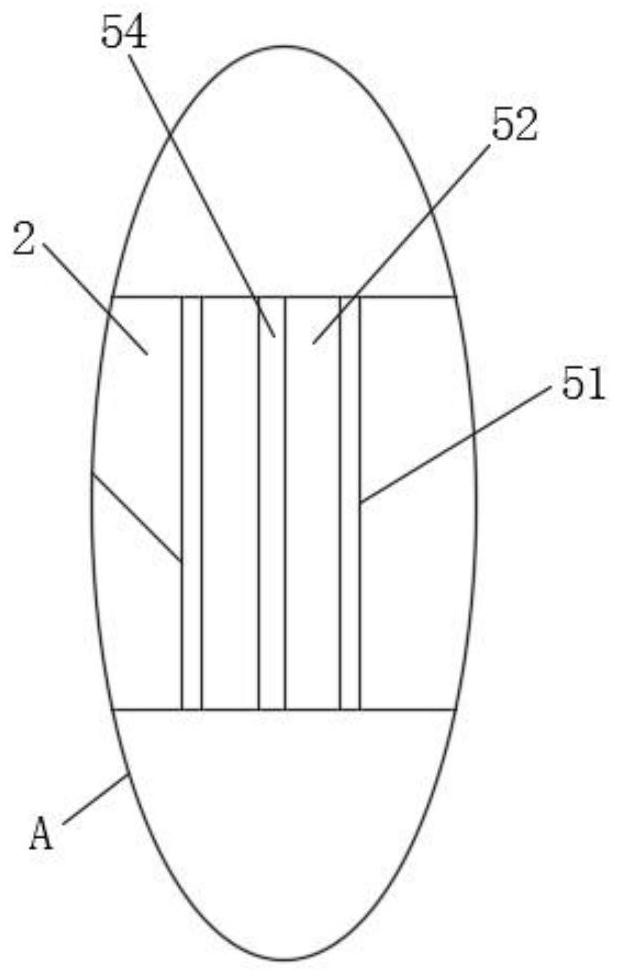

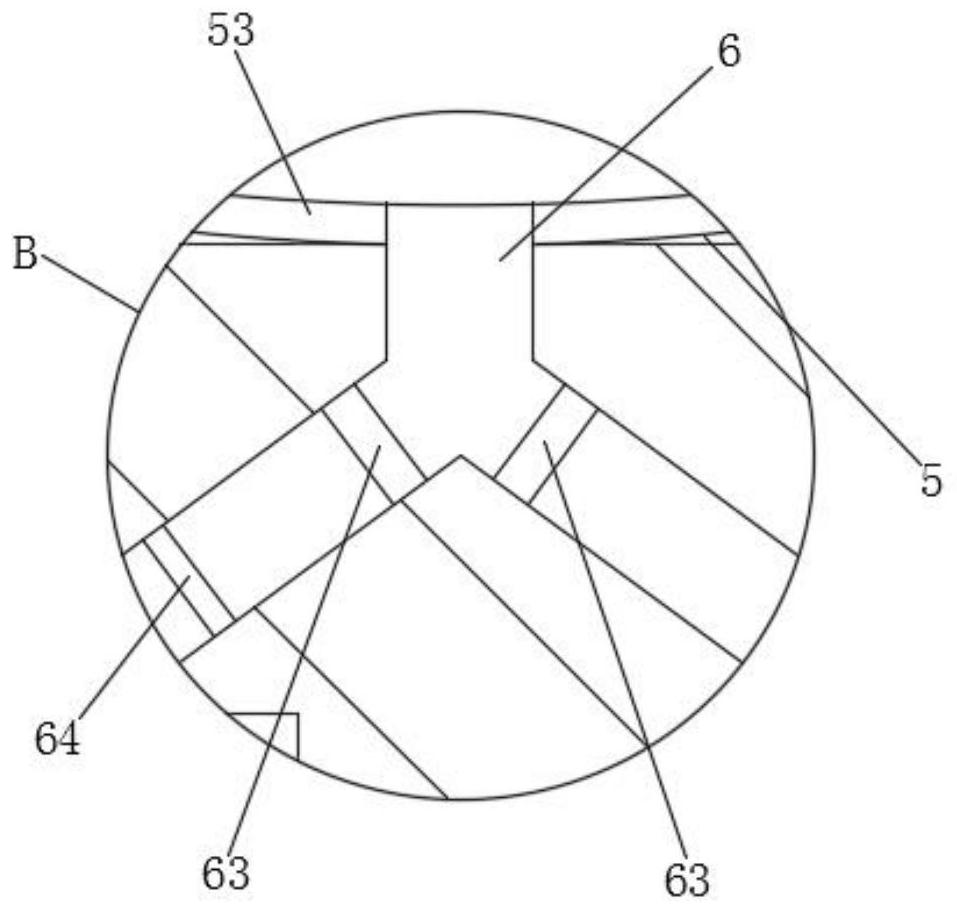

[0024] see Figure 1-4 , the present embodiment provides a cleaning device for feed production and its use method, comprising a U-shaped fixing frame 1, a cleaning bin 2 is hinged between the side walls of the opening end of the fixing frame 1, and the center of the inner wall of the bottom side of the cleaning bin 2 A rotating shaft 3 is installed, and a plurality of groups of stirring plates 4 are arranged on the outer wall of the rotating shaft 3 .

[0025] The side facing the top of the fixing frame 1 is connected to the cleaning chamber 2 through the fixed shaft 11. The front view of the bottom of the cleaning chamber 2 is an arc structure, and the distance between the outer wall of the bottom of the cleaning chamber 2 and the inner wall of the bottom side of the fixing frame 1 is 10-20cm. , the U-shaped fixing frame 1 can facilitate the installation of the cleaning chamber 2, and the connection between the fixed shaft 11 and the cleaning chamber 2 is preferably directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com