Composite stamping automatic production line

An automatic production line, automatic technology, applied in the field of composite stamping, can solve the problems of poor stability, punching interference, complex structure, etc., to achieve smooth movement, improve production efficiency, and play the effect of equipment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

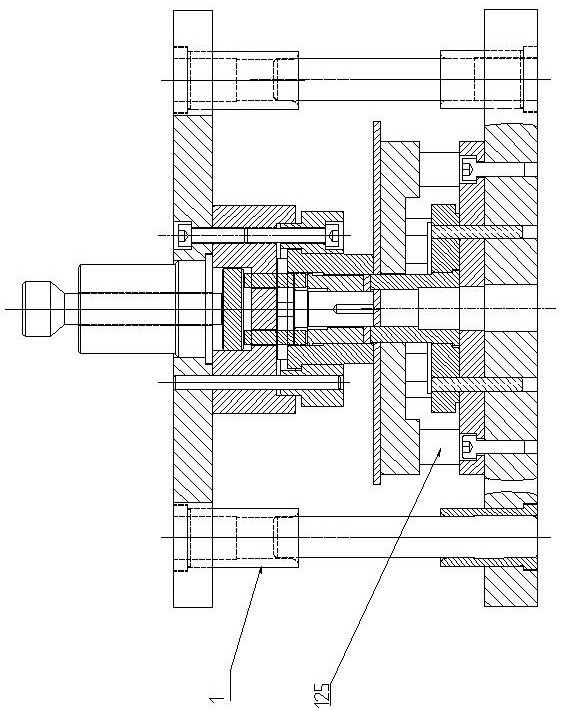

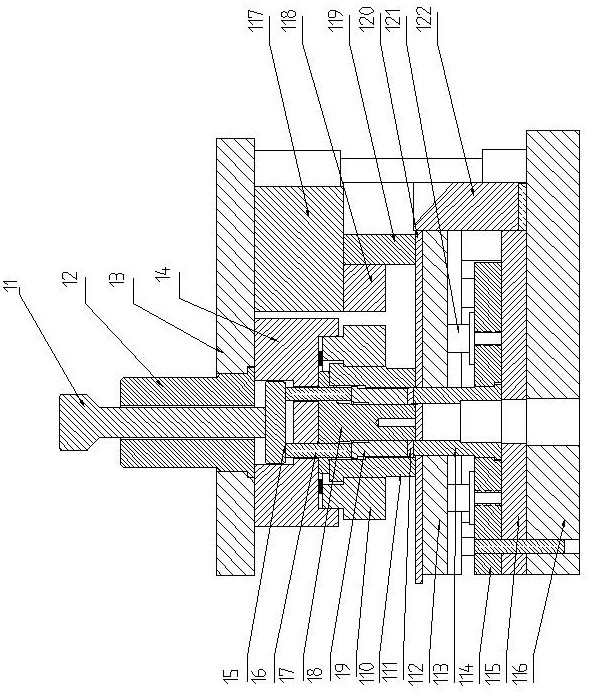

[0054] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

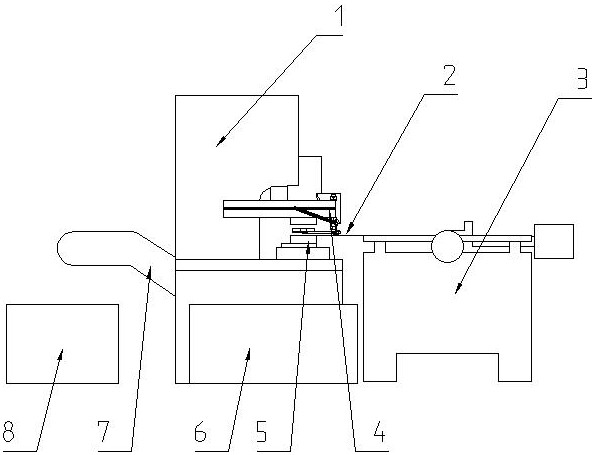

[0055] Such as figure 1 As shown, a compound stamping automatic production line of the present invention includes a punch press 1, a numerically controlled automatic feeder 3, a compound stamping die 2, an automatic material receiving device 4, a workpiece material frame 6, a conveyor 7 and a waste material frame 8.

[0056] The composite stamping die 2 includes an upper die and a lower die, which are installed on the punch press 1 to provide punching force for the die. The CNC automatic feeder 3 clamps the steel plate 4 and sends it between the composite stamping dies 2 for stamping. The automatic material receiving device 4 is installed on the side of the punch press 1, and is used to catch the workpiece withdrawn from the upper die, and throw the workpiece into the workpiece material frame 6 on the side with the movement of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com