Numerical control tool rest buffer mechanism based on reliability consideration

A buffer mechanism and reliability technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as short service life, weak buffer capacity, and inability to reset in time, and achieve long service life and buffer Good effect and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

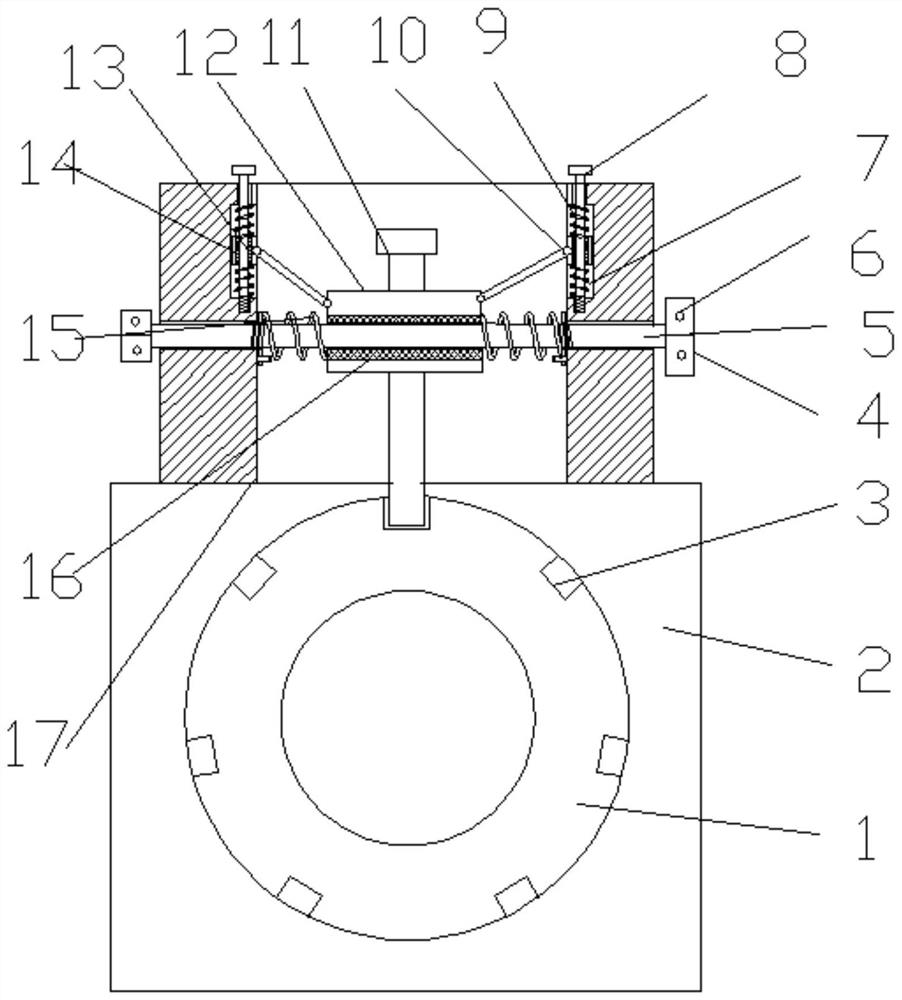

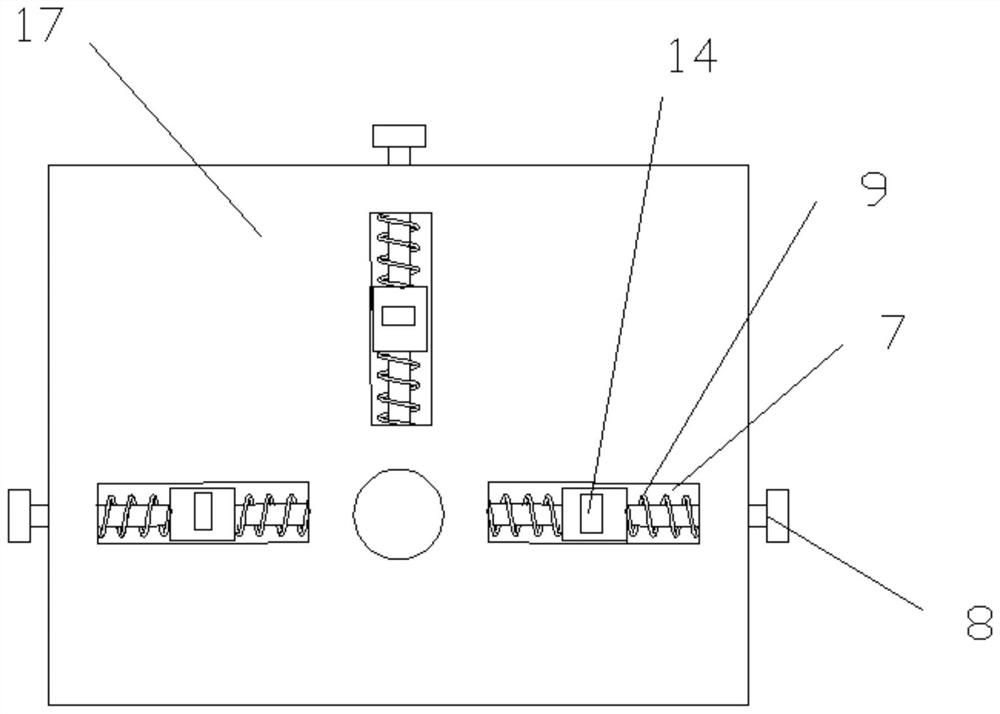

[0025] see Figure 1-2 , the CNC tool post buffer mechanism based on reliability considerations, including the box body 2 and the end cover 17, the inner rotation of the box body 2 is provided with a cam gear 1, and the side wall of the cam gear 1 is uniformly provided with a number of positioning grooves 3 Two end caps 17 are symmetrically fixed on the box body 2, the first screw 5 passes through the two end caps 17 and the end is threadedly connected with a nut 4, and the first screw 5 can be fixed by turning the nut 4 on the end cap 17. The side wall of the nut 4 is provided with an inner hexagonal hole 6, and the setting of the inner hexagonal hole 6 is convenient for inserting the inner hexagonal wrench into the inside of the inner hexagonal hole 6, so as to reduce the torque of the nut 4 and make the screwing of the nut 4 easier. Convenient and quick, thus easy to install. The middle position of the first screw 5 is slidably nested with a sliding pin seat 12, and the i...

Embodiment 2

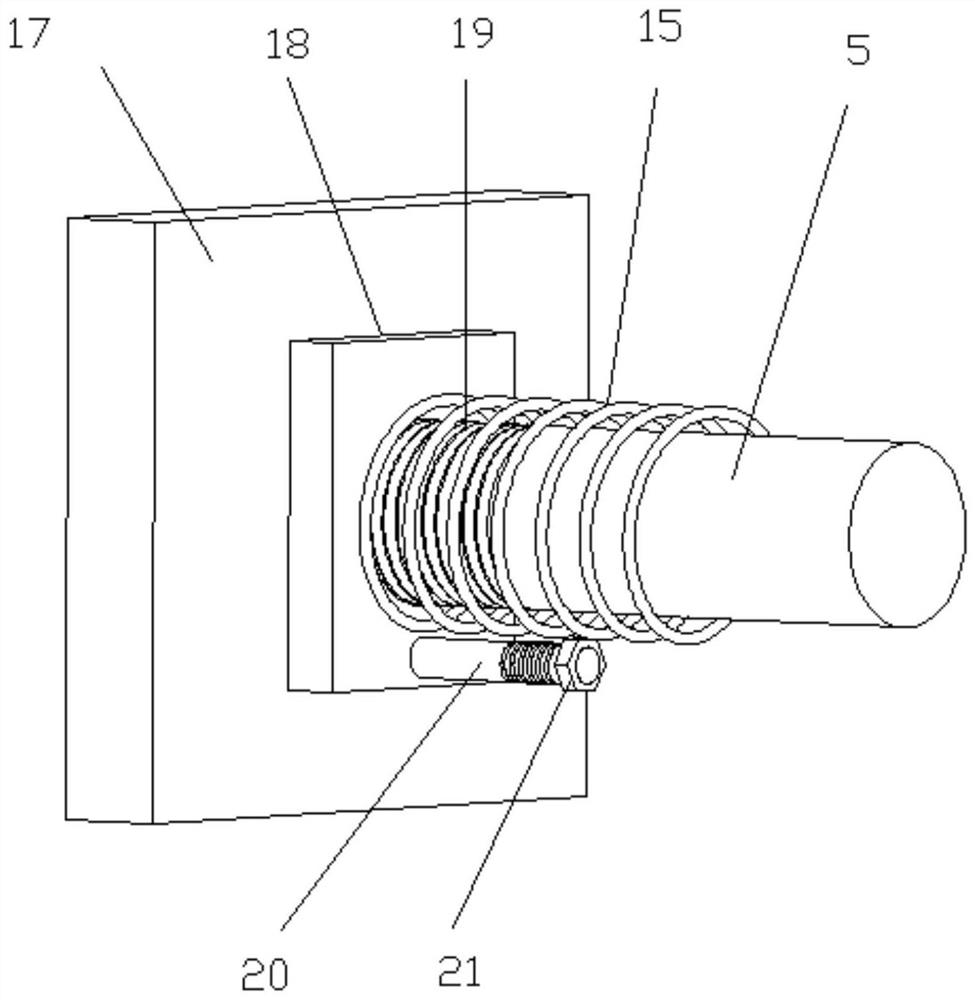

[0028] see image 3, on the basis of Embodiment 1, the inner side of the end cover 17 is symmetrically provided with a threaded part 19 at both ends of the first screw 5, and an extruded plate 18 is threaded on the threaded part 19, and the first screw 5 can be screwed to make The extruding plate 18 moves on the threaded part 19, so that the two extruding plates 18 can move closer or move to both sides, so as to adjust the compression amount of the second spring 15, thereby adjusting the buffer force. The inner side wall of the end cover 17 is fixedly connected to the outer end of the fixed cross bar 20, and the fixed cross bar 20 passes through the extruded plate 18, thereby avoiding the rotation of the extruded plate 18 during the movement. The inner end of the fixed cross bar 20 is provided with a limiting cap 21, and the setting of the limiting cap 21 has a limiting effect on the extruding plate 18, preventing the extruding plate 18 from slipping out of the fixed cross bar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap