Matching grinding method of hydraulic press coupling accessories

A technology for hydraulic presses and accessories, which is applied to the parts of grinding machine tools, grinding devices, grinding racks, etc. It can solve problems such as non-conformity to size requirements, grinding of coupling parts, and affecting product quality, so as to achieve uniform and smooth grinding. The effect of improving quality and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

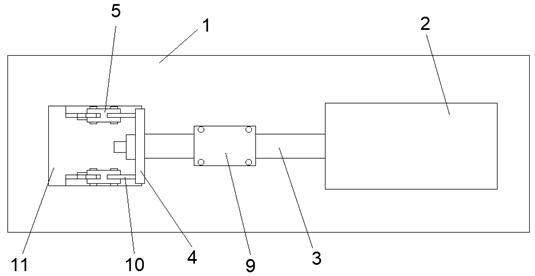

Embodiment 1

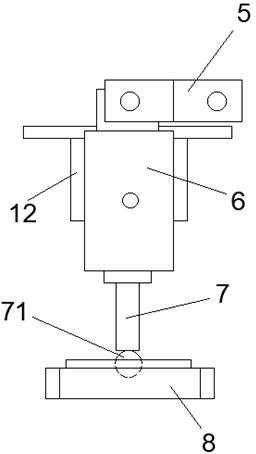

[0041] The first product is the rear cover of the double arc of the hydraulic press, and the second product is the oil separator. According to the shape and size of the double arc rear cover and the oil separator of the hydraulic press, the corresponding rear cover forming and grinding tool and the first product are produced. Oil separator forming and grinding tool, on the back cover forming and grinding tool and the first grinding surface of the first oil separating plate forming and grinding tool is electroplated and adsorbed with a layer of emery with a particle size of 590um.

[0042] When grinding, grind the back cover first. At this time, the grinding tool 8 is the back cover forming grinding tool. The back cover is fixed on the platform under the workbench 1 through a bench vise, and then the back cover forming grinding tool is installed on the back cover. On the grinding surface of the cover, after the rear cover forming and grinding tool is placed, then rotate the plun...

Embodiment 2

[0046] The first product is the pump bladder of the hydraulic plunger pump of the hydraulic press, and the second product is the oil separator. According to the shape and size of the pump bladder and the oil separator of the hydraulic piston pump of the hydraulic press, the corresponding pump bladder forming and grinding tooling and The second oil-separating plate forming and grinding tool is electroplated and adsorbed on the surface of the second grinding surface of the pump bladder forming and grinding tool and the second oil-separating plate forming and grinding tool with a particle size of 710um.

[0047] When grinding, first grind the pump bladder. At this time, the grinding tool 8 is the pump bladder forming and grinding tool. The pump bladder is fixed on the platform under the workbench 1 through a vice, and then the pump bladder forming grinding tool is installed on the pump. On the grinding surface of the bladder, after the pump bladder forming and grinding tool is pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Surface roughness value | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com