Stone-like coating polisher for exterior wall beautifying construction

A technology of real stone paint and sander, applied in grinding machines, manufacturing tools, metal processing equipment, etc., can solve the problems of hand soreness and trouble for staff, reduce manual operation, ensure the quality of grinding, and avoid the effect of floating around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

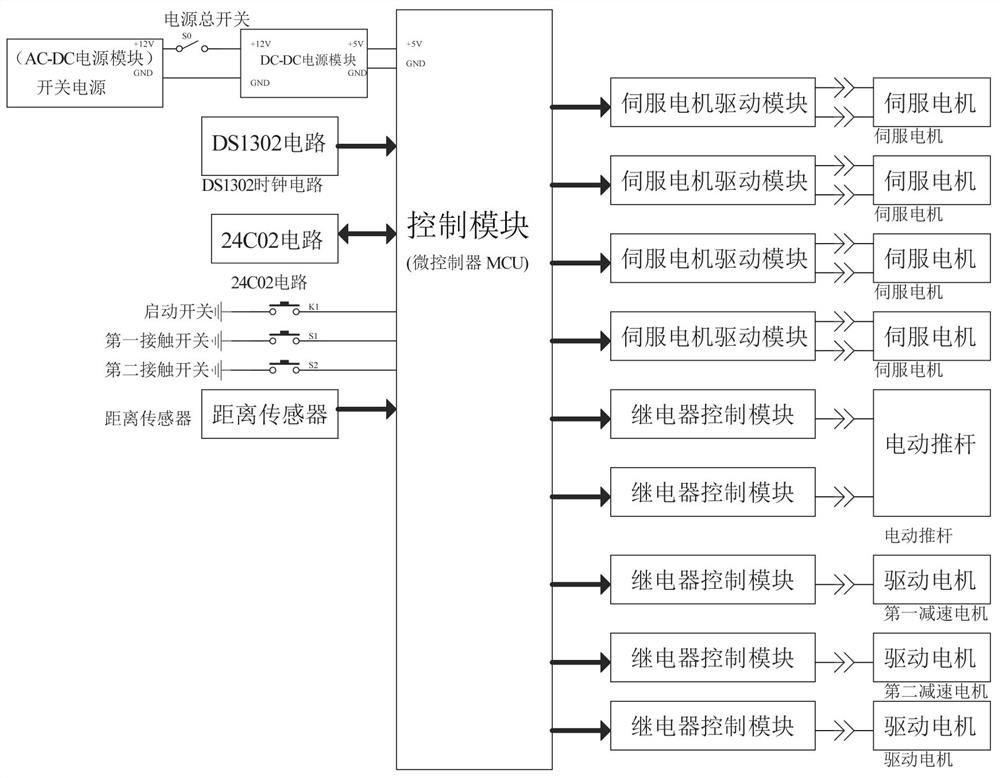

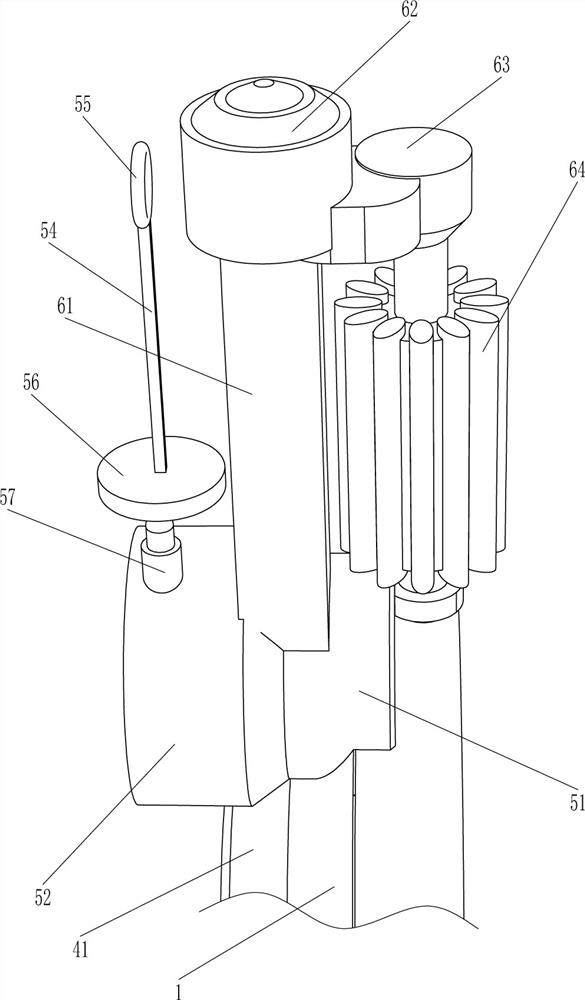

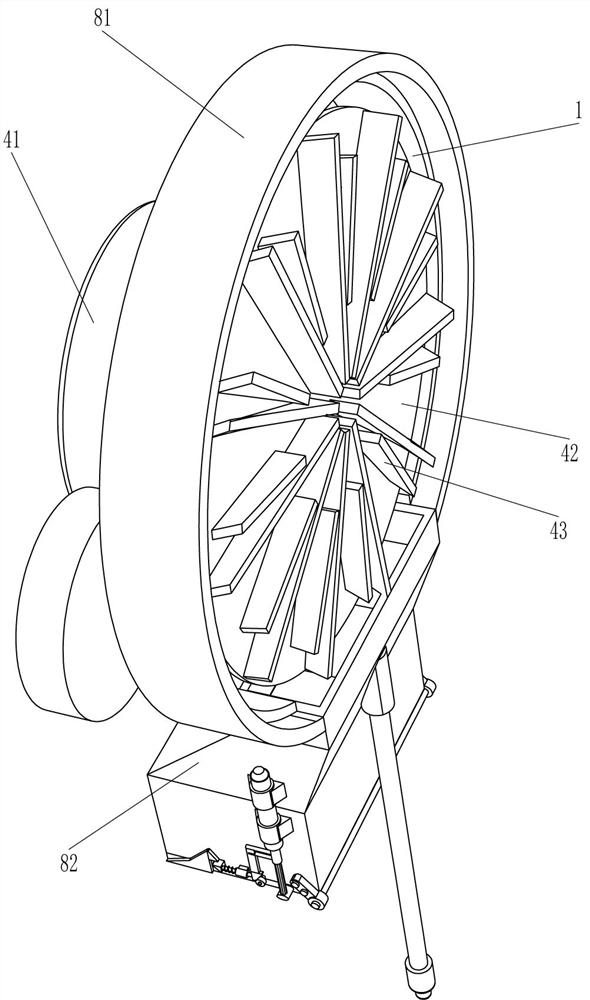

[0030] A real stone paint grinder for exterior wall beautification construction, see Figure 1-3 Shown, comprise installation disc 1, grinding mechanism 4, lifting mechanism 5 and moving mechanism 6, grinding mechanism 4 and lifting mechanism 5 are installed on the installation disk 1, and moving mechanism 6 is installed on the lifting mechanism 5.

[0031] The staff installs the device on the wall, then presses the main power switch to power on the device, then presses the start switch, the start switch sends out a signal, and the control module controls the grinding mechanism 4 to work after receiving the signal, and the grinding mechanism 4 pairs of real stones The paint is polished, and the control module controls the lifting mechanism 5 to drive the device to move upwards, and the real stone paint in other positions is polished. When the device moves upwards to the set position, the control module controls the lifting mechanism 5 to drive the device to move downward. When...

Embodiment 2

[0039] On the basis of Example 1, see figure 1 , figure 2 , Figure 4 , Figure 5 and Figure 6 As shown, a fitting mechanism 7 is also included. The fitting mechanism 7 includes a foot 71, a guide ring 72, a servo motor 73, a fan blade 74, an arc-shaped cavity shell 75, a ball 76 and a distance sensor 77. Before installing the disk 1 There are four supporting legs 71 evenly spaced around the circumferential direction, the outer ends of the supporting legs 71 are connected with guide rings 72, each guide ring 72 is equipped with a servo motor 73, and the output shaft of each servo motor 73 is installed There are fan blades 74, arc-shaped cavity shells 75 are connected to the outside of the guide ring 72, balls 76 are arranged in each arc-shaped cavity shell 75, and distance sensors 77 are installed on the outside of the arc-shaped cavity shells 75.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com