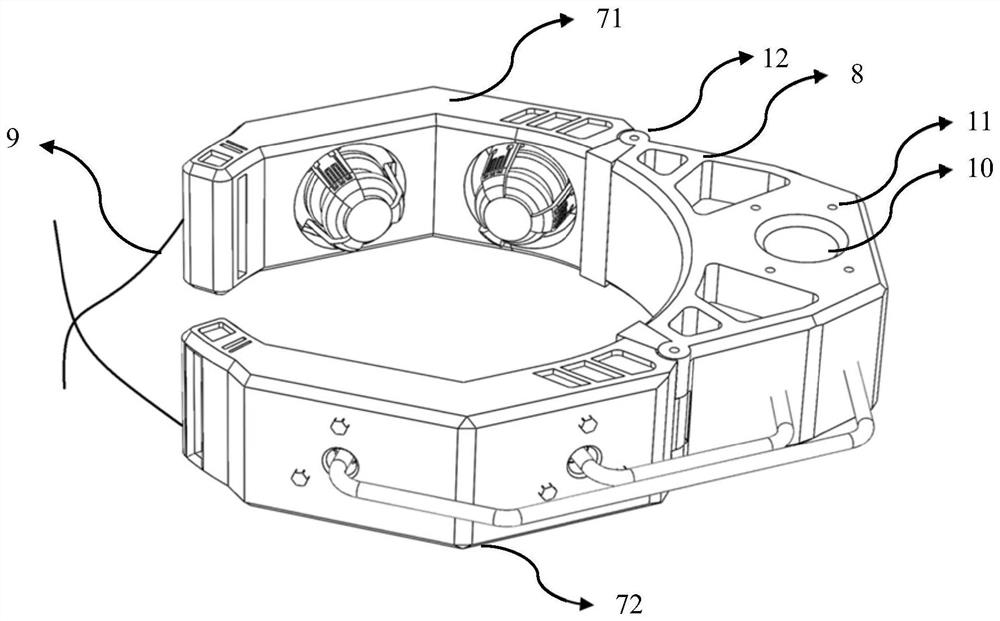

Multi-dimensional force sensor and novel self-adaptive flexible exoskeleton man-machine interface thereof

A multi-dimensional force sensor and human-machine interface technology, applied in the field of multi-dimensional force sensor and its new adaptive flexible exoskeleton human-machine interface, can solve the problems affecting wearing comfort, large pressure peaks, etc., and achieve good human-computer interaction, Low cost and comfortable to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

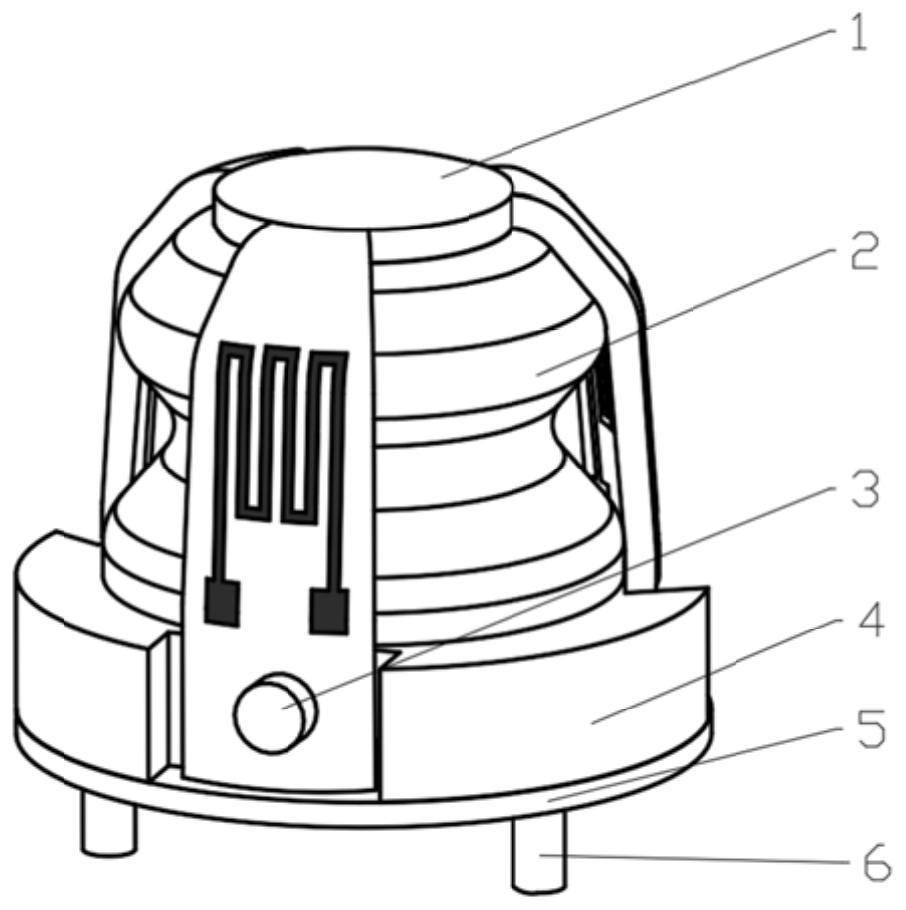

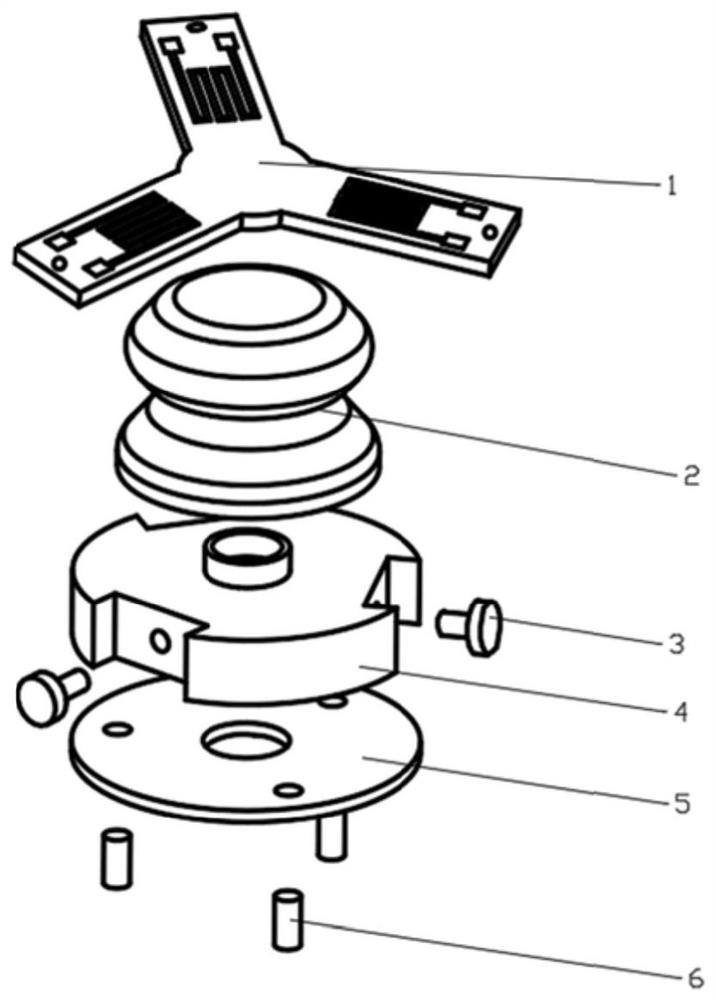

[0034] Such as figure 2 and 3 Shown is a multi-dimensional force sensor of the present invention, which includes a sensor 1, an airbag 2, a base 4 and a circuit board 5. The structure and connection of each component will be described in detail below.

[0035] The airbag 2 is fixedly connected to the top of the base 4 , and the circuit board 5 is fixedly connected to the bottom of the base 4 . In this embodiment, the base 4 is made of resin. The airbag 2 is airtight as a whole, and at least three sensors 1 are evenly arranged along the outer circumferential direction of the airbag 2, and the sensors 1 are resistance strain sensors. One end of each sensor 1 is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com