Battery system connecting and sealing mechanism, automobile body and automobile

A technology of sealing mechanism and battery system, which is applied to the substructure, vehicle components, electric power devices, etc., can solve the problems of poor sealing performance, damage, and unstable fixing, and achieve the effect of stable connection and improved sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

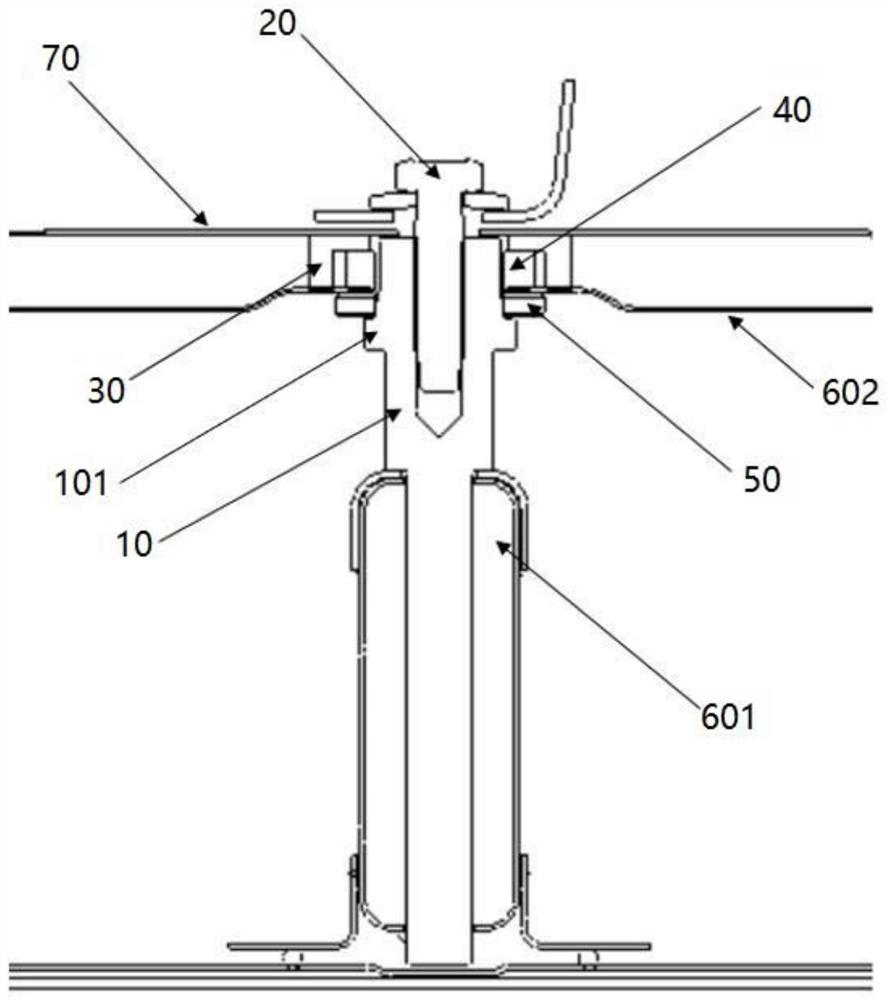

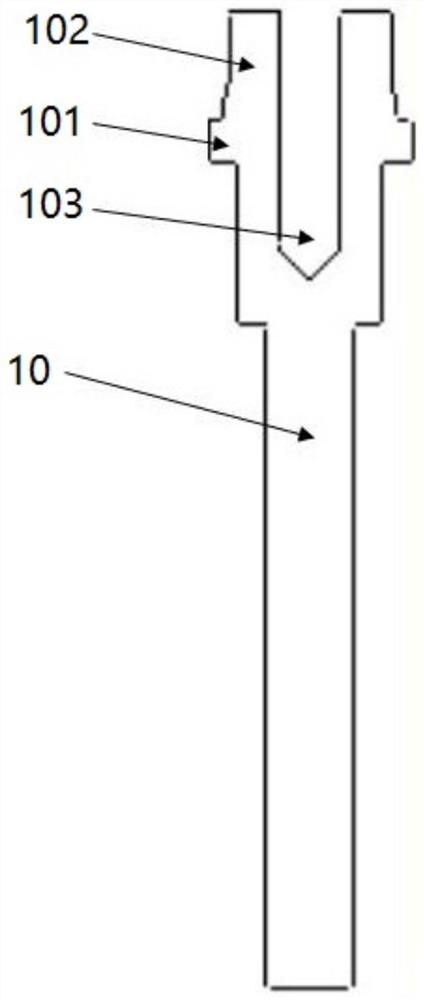

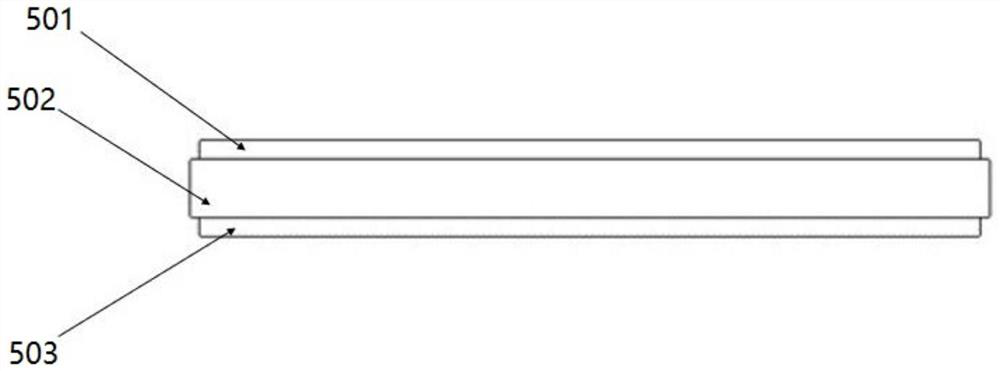

Embodiment 1

[0049]This embodiment discloses a battery system connection sealing mechanism, such asfigure 1 As shown, it includes a connecting pillar 10, a first sealing ring 30, a second sealing ring 50, a first locking member 20 and a second locking member 40, wherein the connecting pillar 10 is used to connect the underbody 70 and the battery pack box. The battery pack case is used to load battery packs. A battery pack composed of several batteries is arranged in the battery pack case. The battery pack case includes a lower tray 601 and an upper cover 602. The connecting pillar 10 and the lower tray 601 are welded and fixed Together, the connecting pillar 10 will not be separated from the lower tray 601. Such asfigure 2 As shown, the upper part of the connecting pillar 10 is a connecting portion 102, and a limiting portion 101 is provided on the outer periphery of the connecting portion 102. In this embodiment, the limiting portion 101 is a bump disposed around the outer peripheral wall of th...

Embodiment 2

[0056]This embodiment discloses a vehicle body. The vehicle body includes the battery system connection and sealing mechanism in Embodiment 1, a vehicle body floor 70 and a battery pack box. The battery pack box is used to place a battery pack, specifically, the battery pack is arranged On the lower tray 601. In this embodiment, the vehicle body floor 70 includes a vehicle body cross member and a vehicle body longitudinal member, and the lower tray 601 includes a pallet cross member and a pallet longitudinal member. The pallet beams or the pallet stringers are welded and fixed together.

[0057]The connecting pillar 10 is connected to the vehicle body cross beam or the vehicle body longitudinal beam to improve the connection strength between the connecting pillar 10 and the vehicle body floor 70 and avoid the vehicle body floor 70 from being deformed by force. In addition, on the main bearing structure of the connecting pillar 10 connecting the vehicle body floor 70, the vehicle body f...

Embodiment 3

[0059]This embodiment discloses a car, which includes the car body in the second embodiment, wherein the car body is applied to a pure electric car, a plug-in hybrid electric car, and a range-extended car with a power battery system arranged outside the vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com