A battery system connecting sealing mechanism, vehicle body and automobile

A sealing mechanism and battery system technology, which is applied to vehicle components, substructures, electric power devices, etc., can solve problems such as poor sealing performance, damage, and loose fixation, and achieve the effect of robust connection and improved sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

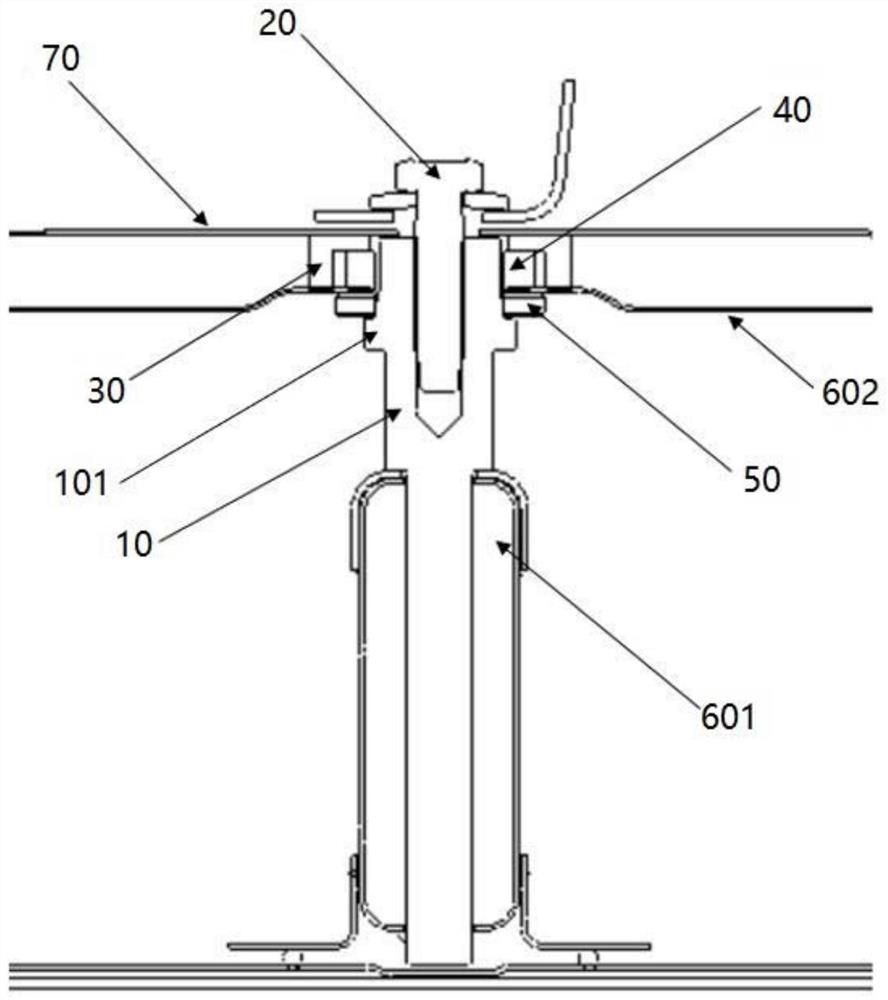

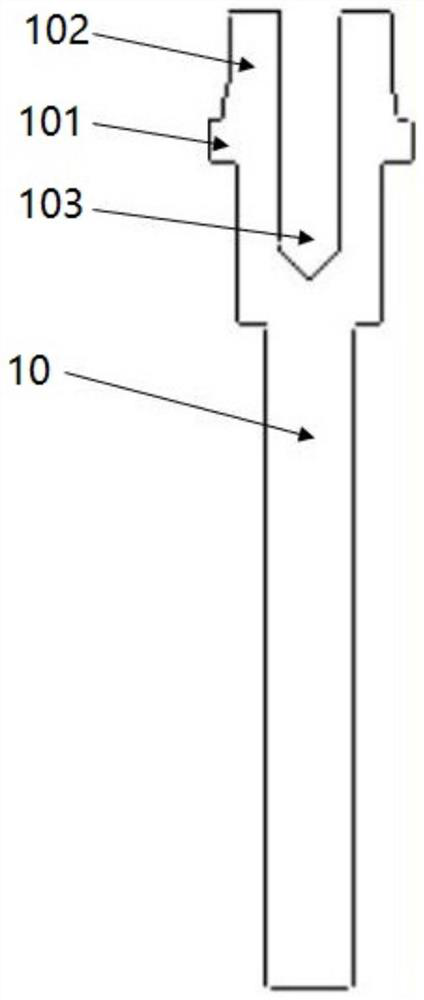

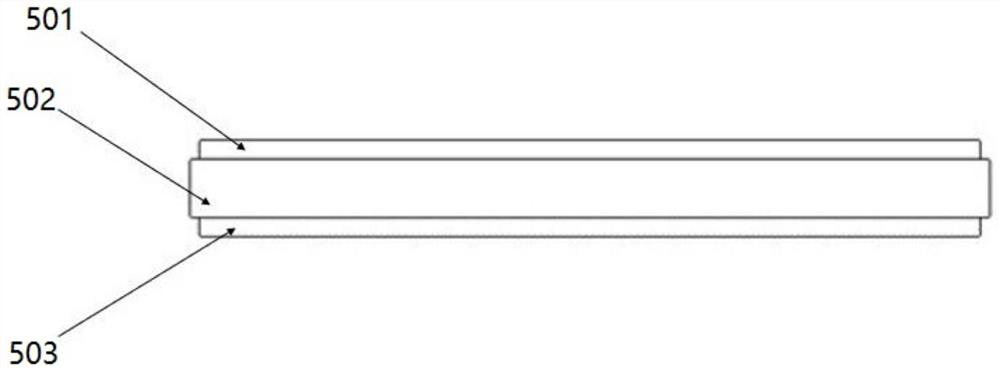

[0049] This example discloses a battery system connection sealing mechanism, such as figure 1 As shown, it includes a connecting strut 10, a first seal ring 30, a second seal ring 50, a first locking member 20, and a second locking member 40, wherein the connecting strut 10 is used to connect the body bottom plate 70 and a battery pack body. The battery pack is used to load the battery pack, and the battery pack consisting of several batteries is disposed in the battery pack body, wherein the battery pack body includes a lower tray 601 and a cap 602, wherein the connecting strut 10 and the lower tray 601 welding is fixed. Together, the connection strut 10 will not be separated from the lower tray 601. like figure 2 As shown, the upper portion of the connecting strut 10 is a connecting portion 102, and the finite portion 101 is provided at the outer circumference of the connecting portion 102, and the limit portion 101 is surrounded by a bump disposed outside the outer peripheral s...

Embodiment 2

[0056] This example discloses a vehicle body including the battery system connection sealing mechanism, body bottom plate 70 and battery pack body in Example 1, wherein the battery pack is used to place a battery pack, specifically, battery pack settings. On the lower tray 601. In the present embodiment, the body bottom plate 70 includes a vehicle body beam and a vehicle body stringer, and the lower tray 601 includes a tray beam and a tray stringer, wherein the upper end of the connecting strut 10 and the vehicle body beam or the body stringer are fixed together, the lower end and The tray beam or tray strip is welded together.

[0057] The connecting strut 10 enhances the connection strength between the connecting struts 10 and the body bottom plate 70 by connecting the body beam or the vehicle body stringer to avoid the force deformed by the body bottom plate 70. Further, the body bottom plate 70 is capable of carrying the battery pack weight on the main body support structure o...

Embodiment 3

[0059] This example discloses a car that includes a vehicle body in Example 2, wherein the body is applied to a power storage battery system, a pure electric vehicle disposed outside the vehicle, plug-in hybrid vehicle and a surrender vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com