Anti-toppling device for chemical transportation machine

An anti-dumping and mechanical technology, applied in the direction of internal parts, external parts, etc., can solve the problems of easy dumping in chemical industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

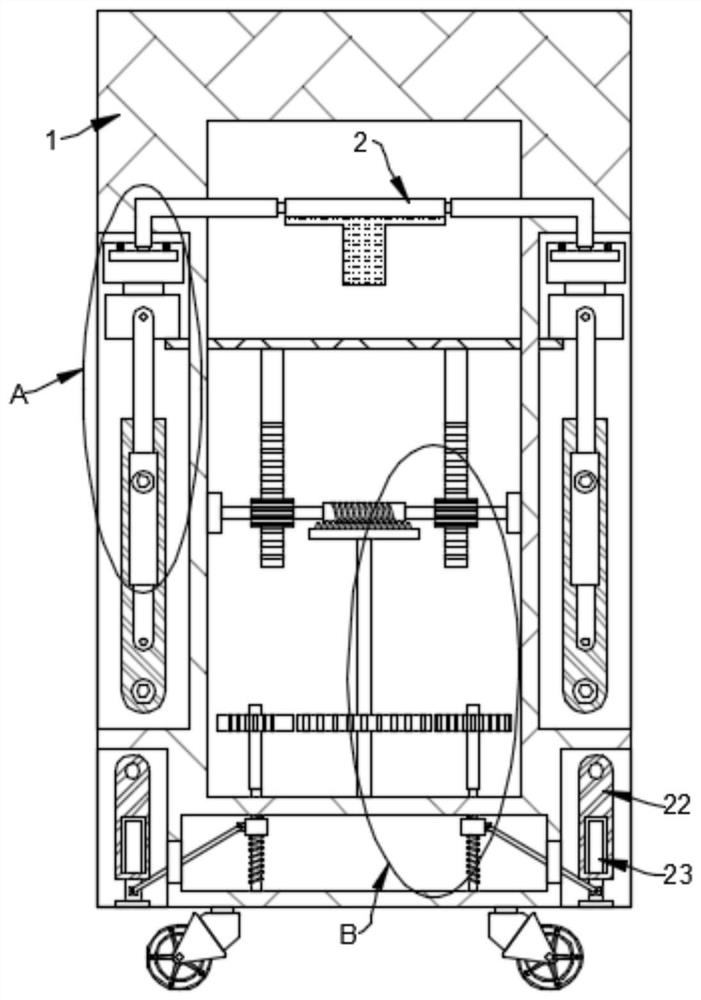

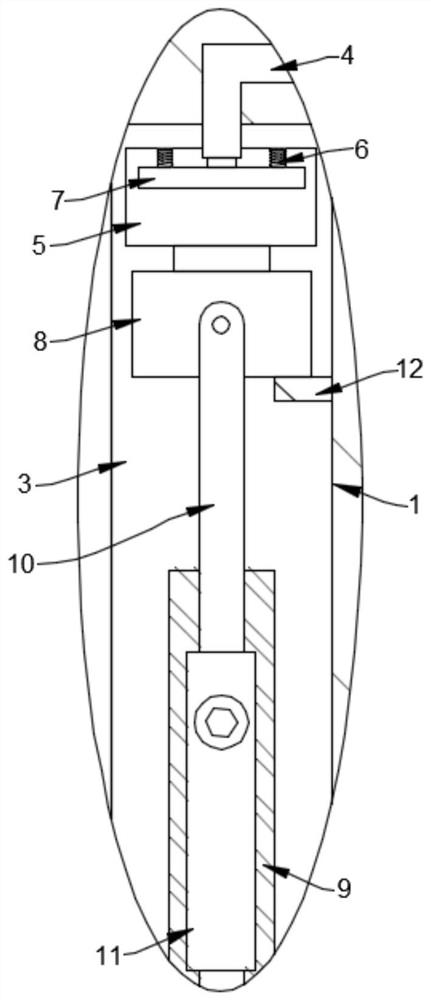

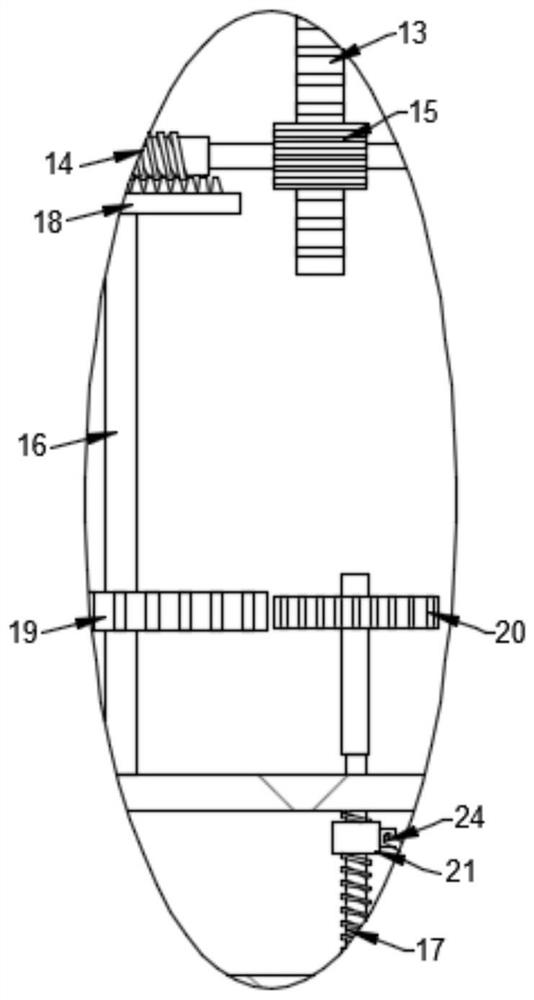

[0026] refer to Figure 1-5 , an anti-dumping device for a chemical transport machine, comprising a body 1 with locking wheels installed at the bottom, a leveler 2 for filling mercury liquid is fixed inside the upper end of the body 1, and side chambers 3 are provided on both sides of the body 1 , the side cavity 3 is provided with a side protection mechanism connected with the leveler 2, and the lower end of the body 1 is provided with a low support mechanism connected with the side protection mechanism;

[0027] For details, refer to the attached figure 1 It can be seen that it needs to be explained that: when the body 1 is horizontal, the mercury liquid is locate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap