General assembly chain type conveying device for diesel engine production

A transmission device and diesel engine technology, which is applied in the direction of cleaning devices, conveyors, conveyor objects, etc., can solve the problems of inability to loosen the transmission chain and tighten it, affect the efficiency of diesel engine production, and cannot transmit operations, etc., to achieve a good tension , improve efficiency, and improve the effect of transmission operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

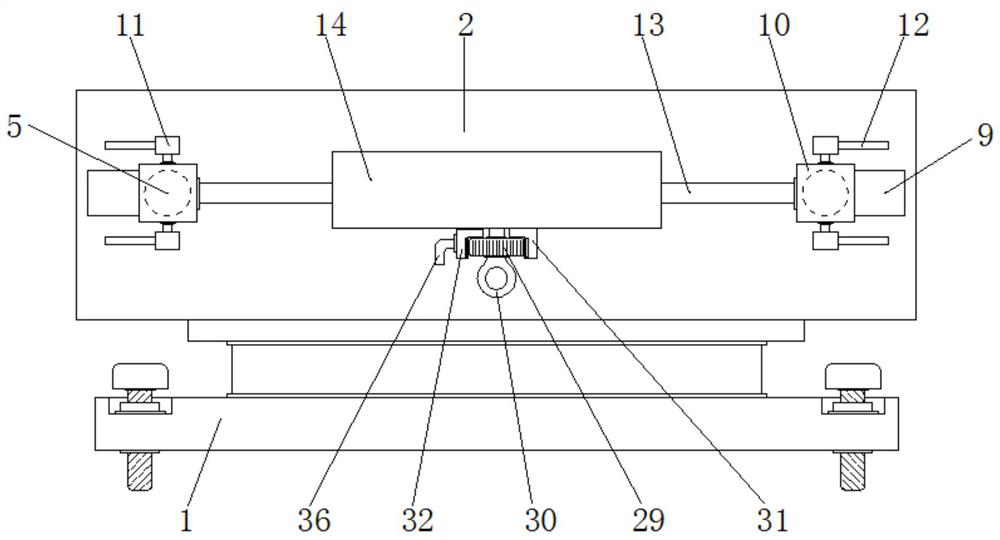

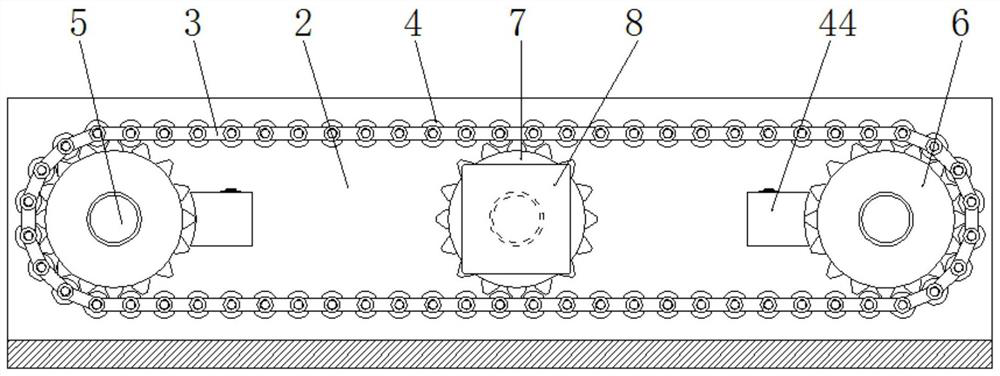

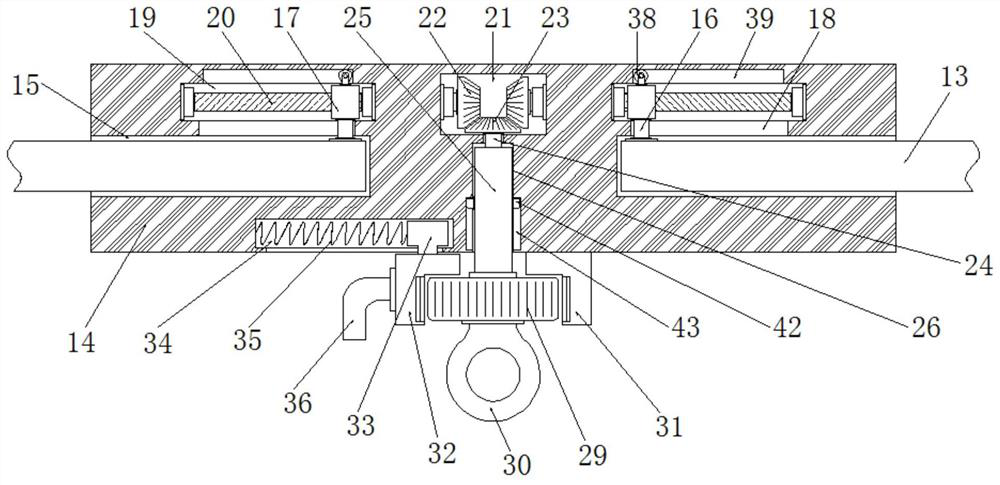

[0030] Embodiment one, such as Figure 1-5As shown, a diesel engine production assembly chain conveyor according to an embodiment of the present invention includes a support base 1, a frame 2 is installed on the top of the support base 1, and a transmission chain 3 is installed inside the frame 2. A transmission roller 4 is installed on the transmission chain 3, shafts 5 are installed at both ends of the transmission chain 3, and guide gears matching the transmission chain 3 are symmetrically installed on the shafts 5 6. A transmission gear 7 compatible with the transmission chain 3 is installed between the guide gears 6, a motor 8 is installed on the transmission gear 7, and the side of the motor 8 away from the transmission gear 7 The side is fixedly connected with the inner side of the frame 2, and the position corresponding to the shaft 5 on the outer side of the frame 2 is provided with a movable groove 9 that is compatible with the shaft 5. A movable block 10 is install...

Embodiment 2

[0031] Embodiment two, such as figure 2 , 5 As shown, the outer side of the conveying roller 4 is provided with a number of anti-skid grooves 37; through the anti-skid grooves 37, the conveying roller 4 can achieve a better anti-skid effect, thereby facilitating better conveying operations, This makes it easier to better meet people's needs.

Embodiment 3

[0032] Embodiment three, such as image 3 As shown, the top of the threaded sleeve 17 is equipped with a positioning pulley 38, and the top of the installation groove one 19 is provided with a pulley groove 39 that is compatible with the positioning pulley 38; through the positioning pulley 38 and The interaction of the pulley grooves 39 can make the threaded sleeve 17 achieve better stability, so that it can move better, and furthermore, it can better meet people's use needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com