A blast furnace ceramic mug with al 2 oc-aln solid solution bonded corundum refractory material and preparation method

A refractory material and solid solution technology, applied in the field of refractory materials, can solve the problems of difficulty in realizing uniform nitrided C-AlN solid solution synthesis, poor high temperature stability, limited industrial production, etc. effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

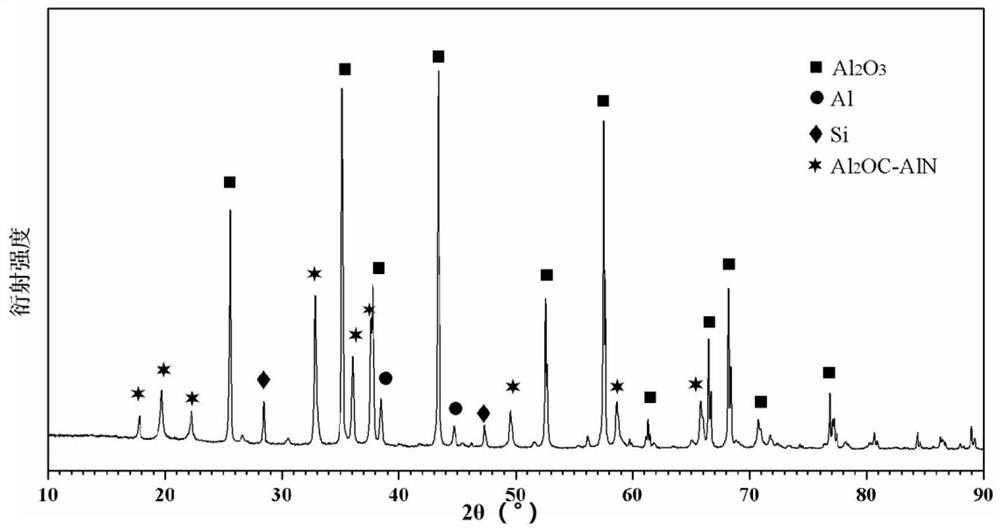

[0015] Example 1: Al for a blast furnace ceramic cup 2 OC-AlN solid solution bonded corundum refractory material and its preparation method, by weight percentage, the raw material composition is: 57% corundum particles with a particle size of 1-3mm, 13% corundum particles with a particle size of 550-600μm, and 14% with a particle size of 38-45μm Corundum fine powder, 12% metal aluminum powder with a particle size of 38-45 μm, 4% silicon nitride powder with a particle size of 38-45 μm, and 3.5% binder phenolic resin by the total weight of the above raw materials. Weigh various raw materials according to the formula, mix them evenly and knead to obtain mud, then press and shape, first dry at 200°C for more than 12 hours, then raise the temperature to 580°C for 8 hours under nitrogen atmosphere, and then sinter at 1600°C for 3 hours. Make the product of the present invention. The diffraction results of the obtained product are attached figure 1 shown. The performance index of ...

Embodiment 2

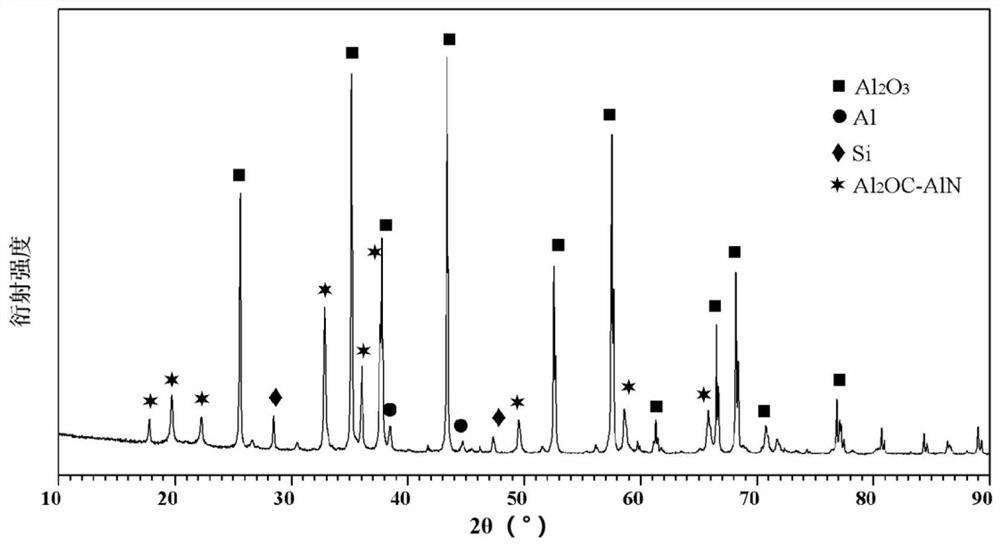

[0016] Example 2: The raw material composition is the same as that of Example 1, but the production process is different. The difference is that the temperature is first raised to 580° C. for 8 hours under a nitrogen atmosphere, and then sintered at 1500° C. for 3 hours to produce the product of the present invention. The diffraction results of the obtained product are attached figure 2 shown. The performance index of the obtained product is: apparent porosity 10.6%, bulk density 3.01g / cm 3 , The compressive strength at room temperature is 326MPa, and its thermal shock resistance, corrosion resistance, oxidation resistance and hydration resistance are all good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com