Preparation method and application of MIL-100(Fe) nanometer catalyst

A nano-catalyst, stirring reaction technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve problems such as high price and easy emission of large organic pollutants , to achieve the effect of simple operation, ultra-high photodegradation performance, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of MIL-100 (Fe) nano-catalyst of the present invention, it comprises the following steps: (a) trimesic acid and inorganic base are dissolved in water to form the first solution; (b) iron source is dissolved in water to form Fe containing 2+ or / and Fe 3+ the second solution; (c) drop the first solution into the second solution, filter after stirring and reacting, rinse with ethanol, dry, and collect the filter cake; the trimesic acid, the The molar ratio of the inorganic base to the iron element is 1:2-3.5:1-1.5. The preparation method of MIL-100 (Fe) nano-catalyst of the present invention, by making trimesic acid and inorganic base react to form trimesic acid radical ion and can cooperate with iron ion or ferrous ion to form MIL- with high crystallinity 100(Fe), the reaction can quickly synthesize highly crystalline MIL-100(Fe) at room temperature, the reaction solvent is water, avoiding the use of a large amount of organic solvents, and no corro...

Embodiment 1

[0029] The present embodiment provides a kind of preparation method of MIL-100 (Fe) nano-catalyst, it comprises the following steps:

[0030] (a) Add NaOH (10.0g) into a round bottom flask, add 250mL of water to dissolve, and dissolve trimesic acid (H 3 btc, 16.7g) was added in portions, stirred to obtain a clear solution (i.e. the first solution);

[0031] (b) FeSO 4 ·7H 2 O (31.7g) was dissolved in 1000mL of water to obtain the second solution;

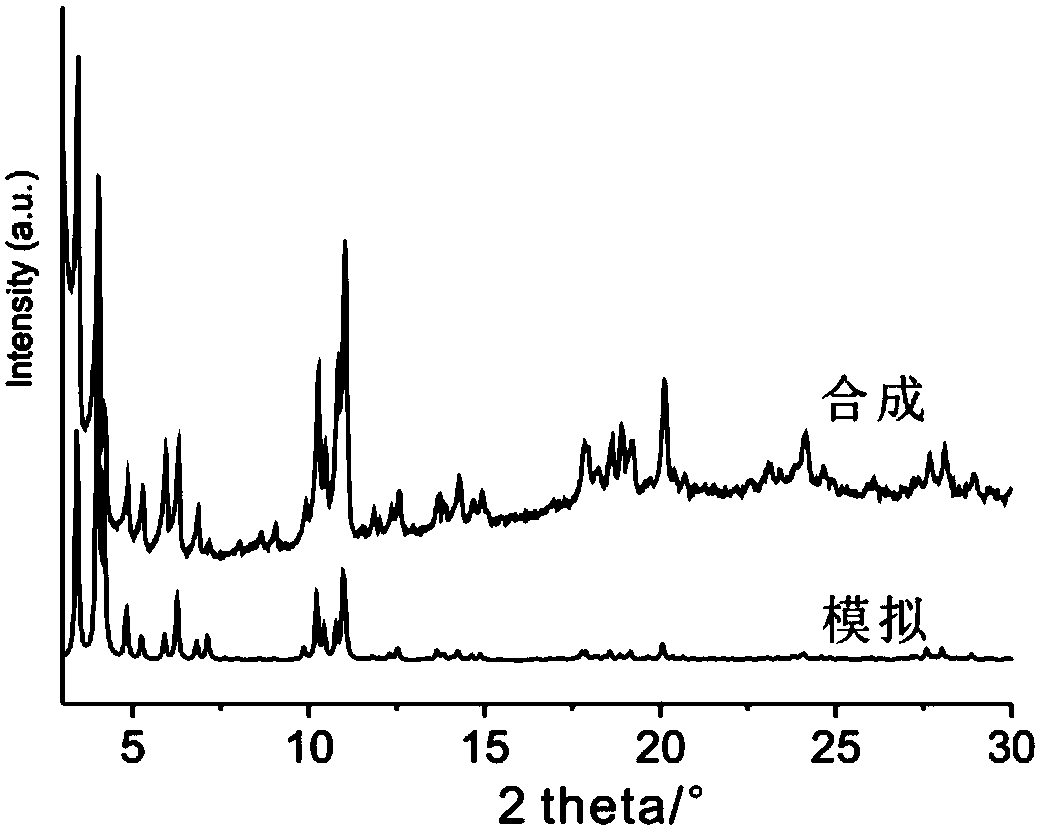

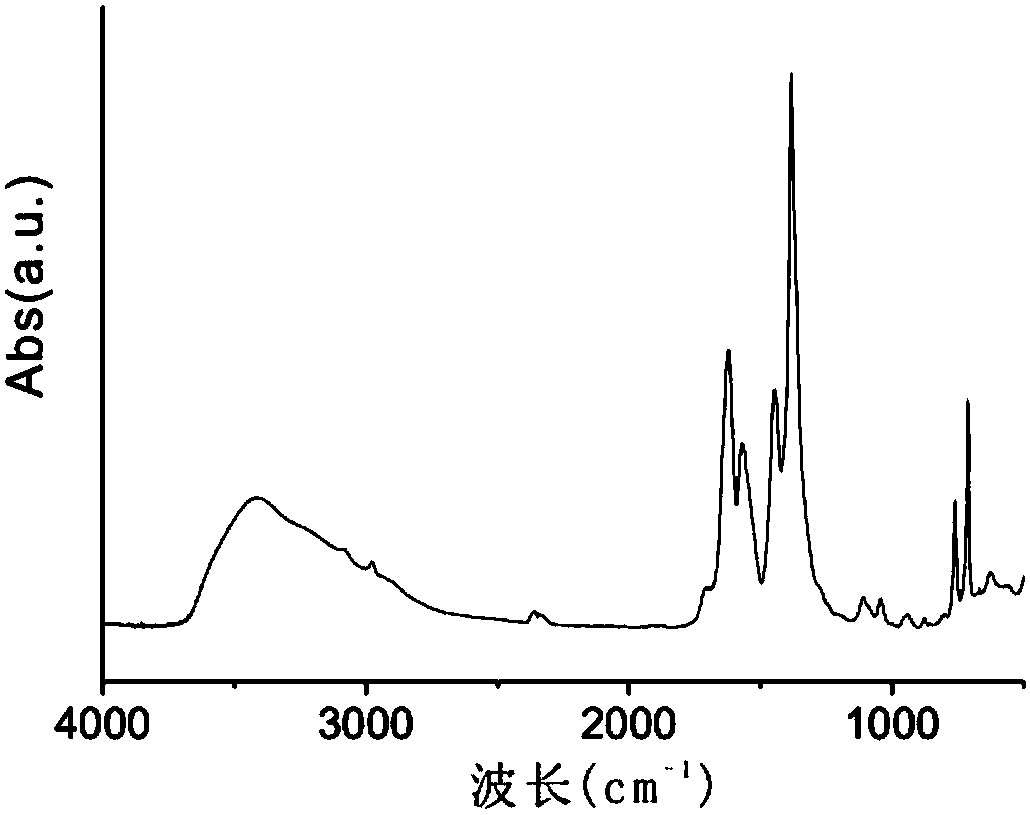

[0032] (c) Add the first solution dropwise to the second solution (dropping with a conventional dropper, about 1-5 drops / second, the same below) under stirring at room temperature (25°C), and stir for 12 hours; Filter, rinse the filter cake with water and ethanol, dry, and collect the filter cake. Carry out SEM, XRD and infrared test to the obtained product, the results are as follows Figure 1 to Figure 3 Shown; It can be seen that the obtained MIL-100 (Fe) particles have a particle size of 500-1000nm and a high degree of crysta...

Embodiment 2

[0034] The present embodiment provides a kind of preparation method of MIL-100 (Fe) nano-catalyst, it comprises the following steps:

[0035] (a) Add NaOH (10.0g) into a round bottom flask, add 250mL of water to dissolve, and dissolve trimesic acid (H 3 btc, 16.7g) was added in portions, stirred to obtain a clear solution (i.e. the first solution);

[0036] (b) FeCl 2 4H 2 O (22.6g) was dissolved in 1000mL of water to obtain the second solution;

[0037] (c) Add the first solution dropwise to the second solution (using a conventional dropper, about 1-5 drops / second, the same below) under stirring at room temperature (25°C), and stir for 10 hours; the above filtrate Filter, rinse the filter cake with water and ethanol, dry, and collect the filter cake.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com