Preparation method of micron polycrystalline cubic boron nitride grinding material

A cubic boron nitride and abrasive technology, which is applied in the field of preparation of micron polycrystalline cubic boron nitride abrasives, can solve the problems of decreased fracture toughness and no improvement in hardness, so as to achieve full utilization, reduce production costs, and reduce inventory.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

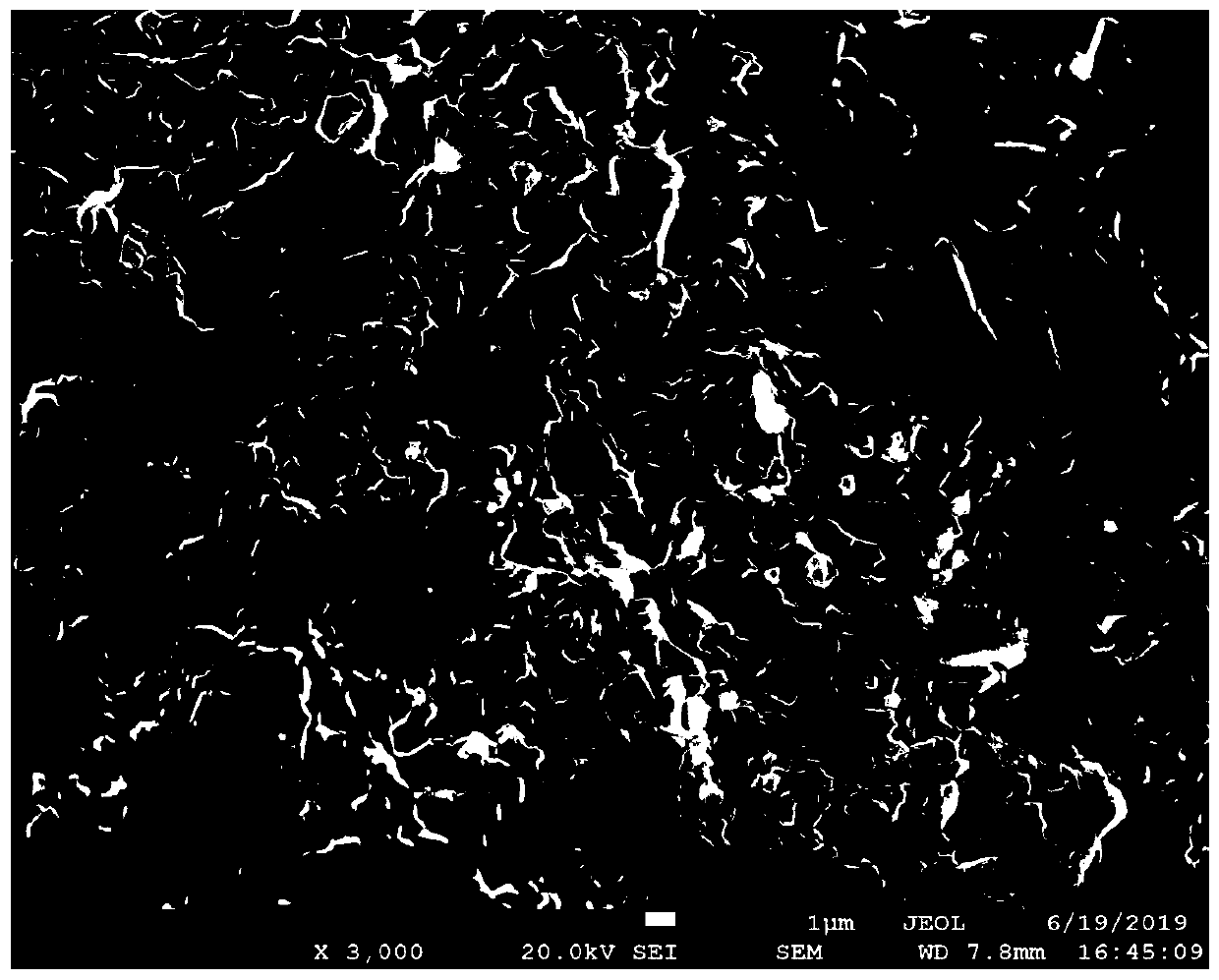

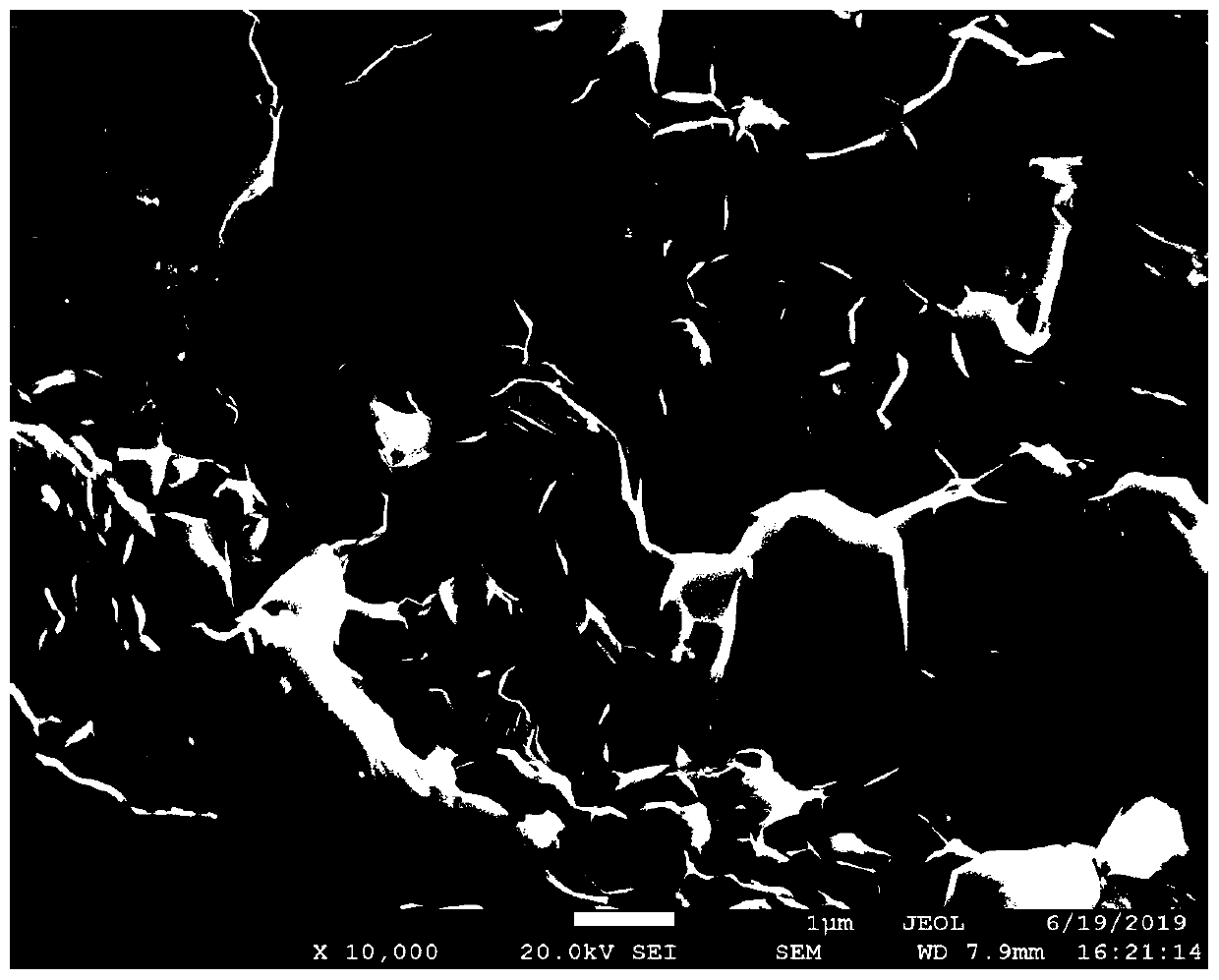

Image

Examples

Embodiment 1

[0026] In this embodiment, the cBN micropowder with a particle size of 0-1 μm is used as a raw material, and the mass 30% of the cBN micropowder is added with B n h n+6 , to obtain the sample to be processed; put the obtained sample to be processed into a three-dimensional mixer and mix for 30 hours; after the mixture is taken out, it is pressed and formed on a hydraulic press to obtain the column required for synthesis; the compressed column is placed in the Treat in a high-temperature vacuum furnace at 1600°C for 3 hours; after cooling down, pass nitrogen gas into the micropores in the column, take it out after 1 hour, and carry out vacuum packaging for standby; put the column under the condition of 6GPa and 1500°C The synthesis is carried out for 5 minutes to obtain a sintered body; the sintered body is crushed, ball milled and sieved to obtain a micron polycrystalline cBN abrasive.

Embodiment 2

[0028] In this embodiment, cBN micropowder with a particle size of 1-2 μm is used as a raw material, and a boron source (a mixture of crystalline boron and amorphous boron) with a mass of 5% of the cBN micropowder is added to obtain a sample to be treated; the resulting sample to be treated is placed in Mix in a three-dimensional mixer for 20 hours; after taking out the mixture, press it on a hydraulic press to obtain the column required for synthesis; process the pressed column in a high-temperature vacuum furnace at 1200°C for 2 hours; after cooling , nitrogen gas is introduced to make the nitrogen gas enter the micropores in the column, take it out after 1 hour, and carry out vacuum packaging for standby; the column is synthesized under the conditions of 10GPa and 2000°C for 15 minutes to obtain a sintered body; the sintered body is crushed Finally, the micron polycrystalline cBN abrasive is obtained after ball milling and sieving.

Embodiment 3

[0030] In this embodiment, cBN micropowder with a particle size of 0-1 μm is taken as a raw material, and amorphous boron with a mass of 20% of the cBN micropowder is added to obtain a sample to be treated; the obtained sample to be treated is put into a three-dimensional mixer and mixed for 10 hours; After the mixture is taken out, it is pressed and formed on a hydraulic press to obtain the column required for synthesis; the pressed column is treated in a high-temperature vacuum furnace at 1200°C for 1 hour; after cooling down, nitrogen gas is introduced to allow nitrogen to enter the column In the micropores in the body, take it out after 2 hours, and carry out vacuum packaging for standby; synthesize the cylinder at 7.7GPa and 1800°C for 15 minutes to obtain a sintered body; crush the sintered body, then ball mill and sieve it A micron polycrystalline cBN abrasive is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com