An evaluation system and method for dynamic direct current corrosion risk of buried metal pipelines

A metal pipeline and risk technology, which is applied in the field of evaluation system for dynamic DC corrosion risk of buried metal pipelines, can solve problems such as no explanation, fluctuation of instantaneous power-off potential of inspection sheet, and division of pipeline corrosion risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

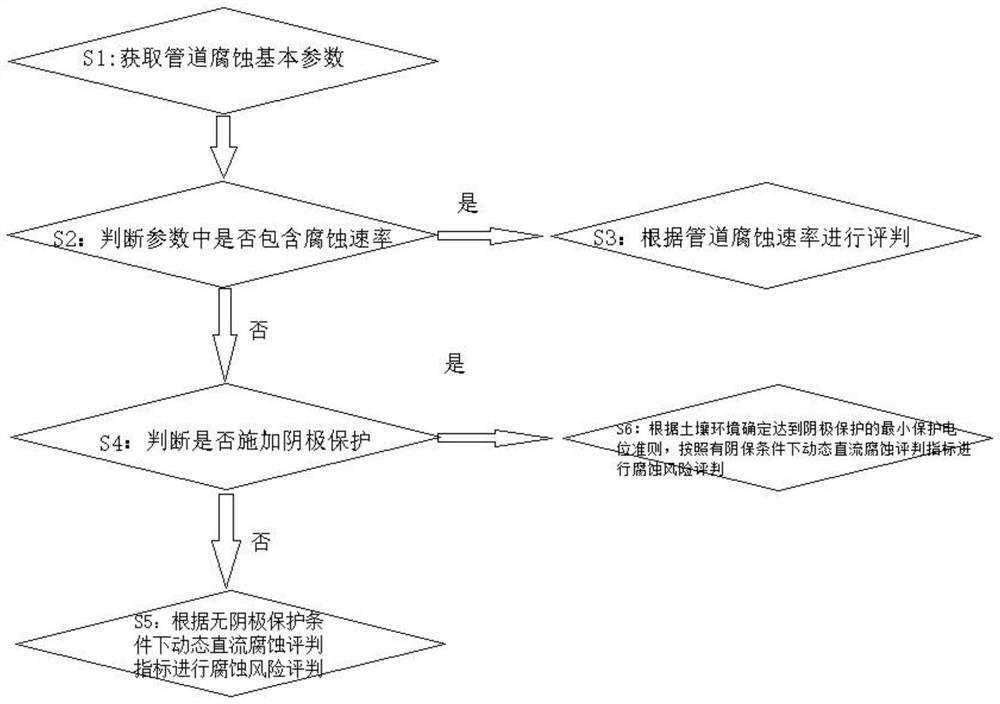

Method used

Image

Examples

Embodiment 1

[0078] In order to realize the purpose of the present invention, collected a large amount of on-the-spot corrosion inspection sheet embedding test and laboratory simulation experiment data, at first determined to corrode rate V corr The high, medium and low three-level evaluation indicators for evaluating the risk of pipeline corrosion are shown in Table 1.

[0079] Table 1 Three-level indicators of pipeline corrosion risk assessment based on corrosion rate

[0080]

[0081] In the process of rail transit dynamic DC stray current corrosion risk assessment, if the corrosion rate of the pipeline can be obtained by testing the corrosion weight loss inspection sheet, ER corrosion probe, on-line detection equipment or other proven effective detection methods, the corrosion rate can be determined according to the corrosion rate. The test results are used to judge the risk of pipeline corrosion.

[0082] When the corrosion rate data cannot be obtained directly, the corrosion rate...

Embodiment

[0095] (1) A pipeline is subjected to dynamic DC stray current interference, and the corrosion rate V of pipeline steel is obtained through the embedding test of the corrosion weight loss check corr Reaching 0.15mm / a, the risk of pipeline corrosion is high.

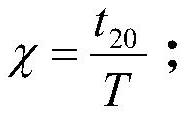

[0096] (2) The gas pipeline in a certain city suffers from dynamic DC stray current interference, without cathodic protection, the natural corrosion potential E corr -0.73V CSE , the pipe polarization potential E off Relative natural corrosion potential E corr The time for a positive shift of 20mV is 648s, the total test time is 5675s, the proportion of the time when the pipeline polarization potential is positively shifted by 20mV relative to the natural corrosion potential χ is 11%, the corrosion rate is 0.069mm / y, and the pipeline corrosion risk is medium level.

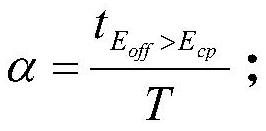

[0097] (3) A certain pipeline suffers from dynamic DC stray current interference, the cathodic protection system works well, the environment medium is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com