Bucket for excavator and using method

A technology for excavators and buckets, applied in the field of excavator accessories, can solve problems such as large gaps and poor bucket space utilization, and achieve the effects of reducing the difficulty of cleaning, improving utilization, and reducing gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

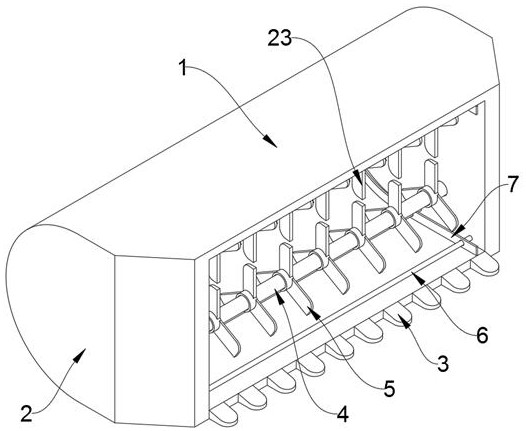

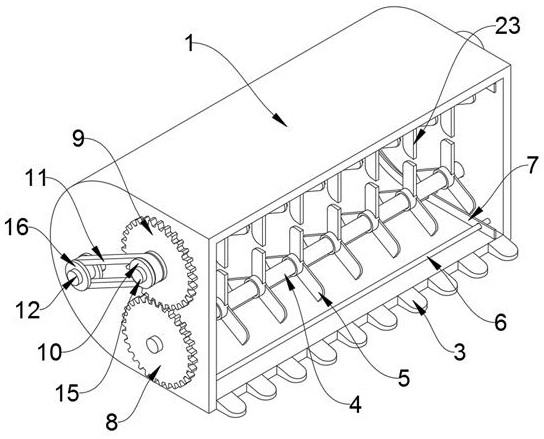

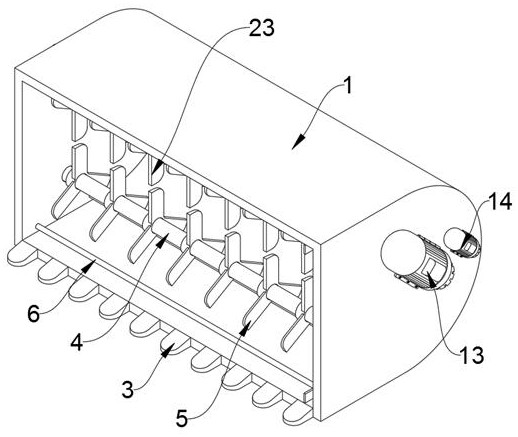

[0036] see Figure 1-7 As shown, the present invention is a bucket for an excavator, including a mechanical excavating bucket body 1, and a straight cavity and a semicircular cavity are opened inside the mechanical excavating bucket body 1, and the straight cavity is located in the mechanical excavating bucket body. The front end of the interior of 1 has a rectangular cross section. The semicircular cavity is located at the rear end of the mechanical excavation bucket body 1, and its cross section is semicircular. A plurality of third pulverizing knives 23 are clamped on the outside of the transmission shaft 15, a first rotating shaft 4 is rotatably connected to the lower end inside the flat cavity, and a plurality of first pulverizing knives 5 are clamped on the outside of the first rotating shaft 4, and The cutting direction of the first pulverizing tool 5 and the cutting direction of the third pulverizing tool 23 are in the opposite direction, the inside of the semicircular...

Embodiment 2

[0046] A method for using a bucket of an excavator is disclosed on the basis of Embodiment 1, the steps of which are as follows:

[0047] The first step: when in use, assemble the device on the arm of the excavator, and then use the excavator control device to excavate the soil, and the soil blocks will be dug into the interior of the mechanical excavator body 1 during excavation;

[0048] Second step: start the first motor 13 in the process of digging, and the first driven bevel gear 18 will be driven to rotate after the first motor 13 is started, because the first driven bevel gear 18 and the first driving bevel gear 19 pass through Mesh connection, when the first driven bevel gear 18 rotates, it will drive the first driving bevel gear 19 to rotate, and when the first driving bevel gear 19 rotates, it will drive the second rotating shaft 12 to rotate together, and when the second rotating shaft 12 rotates, it will Drive the second crushing tool 17 to crush the soil clods ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com