Reliability test system suitable for vehicle-specification-level power/electronic device

A test system and electronic device technology, applied in the field of power electronics, can solve the problems of difficulty in meeting the requirements of vehicle-level power/electronic device testing, poor configurability, and complicated devices, so as to reduce the investment of test equipment and personnel, The effect of improving efficiency and reducing test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

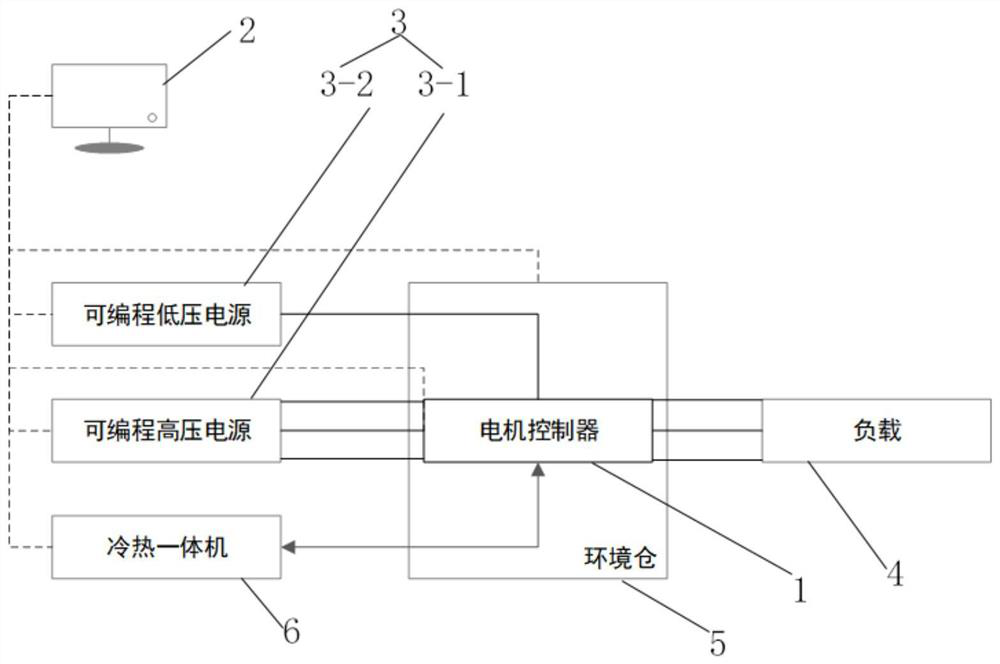

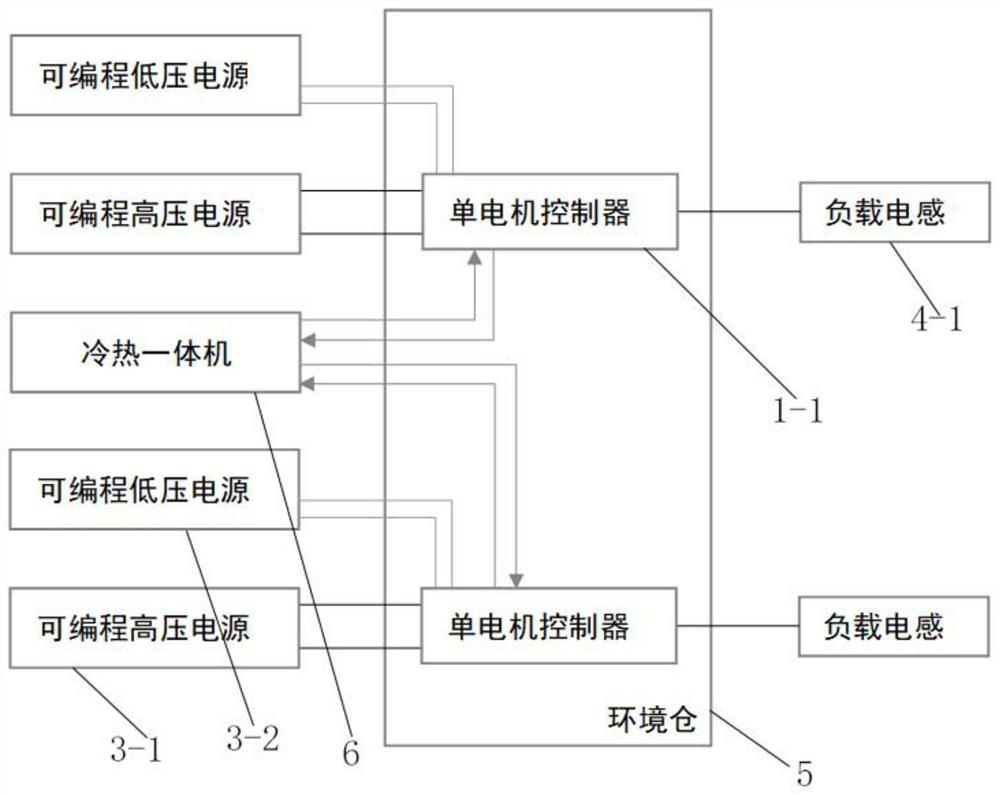

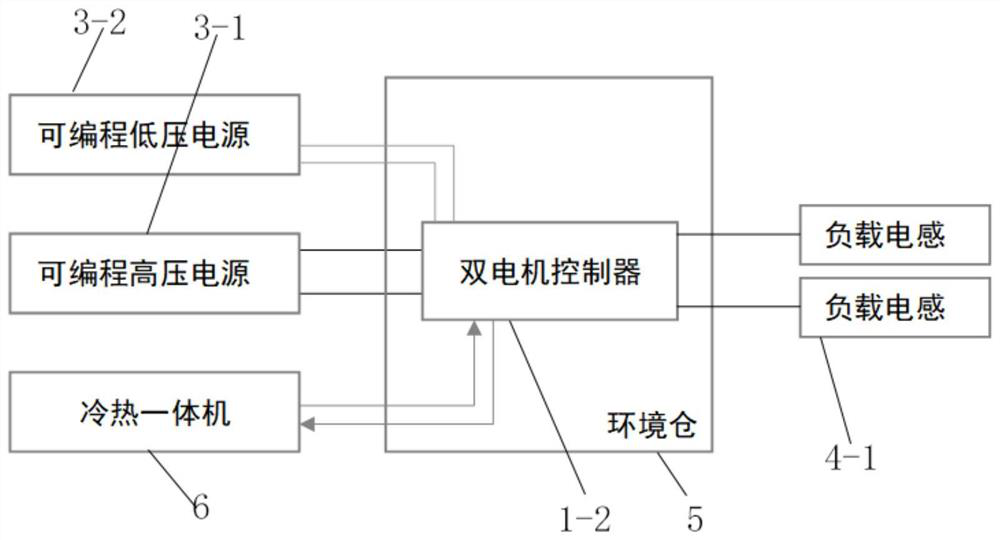

[0031] This embodiment provides a reliability test system suitable for vehicle-level power / electronic devices. In this embodiment, please refer to figure 1 As shown, the reliability test system includes several motor controllers 1 , central control system 2 , programmable power supply components 3 , and loads 4 .

[0032] Wherein, the input end of each motor controller 1 is respectively electrically connected to the programmable power supply assembly 3, and the output end of each motor controller 1 is respectively electrically connected to the load 4, the motor controller 1, the programmable power supply assembly 3, the load 4 The three are connected through cables and signal harnesses to form the electrical circuit of the vehicle-level power / electronic device to be tested.

[0033] In this embodiment, the programmable power supply component 3 includes a programmable high-voltage power supply 3-1, a programmable low-voltage power supply 3-2, and the programmable high-voltage p...

Embodiment 2

[0040] As an improvement to the reliability test system of the first embodiment, in order to avoid interference from the external environment, the stability of the working environment of the motor controller 1 is ensured. Such as figure 1 As shown, the reliability testing system also includes an environment chamber 5 . The environmental chamber 5 is connected to the central control system 2 by communication, and there are several motor controllers 1 in the environmental chamber 5. The environmental chamber 5 is used to provide the motor controller 1 with an ambient temperature of Provides thermal stress at different temperatures.

[0041] As an improvement to the reliability test system of this embodiment and Embodiment 1, when the external temperature environment changes or the motor controller 1 generates a lot of heat, the temperature of the working environment of the motor controller 1 will increase or decrease, affecting the motor control. normal operation of device 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com