Waveguide structure of annular resonant cavity with notch

A waveguide structure, resonant cavity technology, applied in the directions of light guide, optics, instruments, etc., can solve the problems of poor processing capability and integration, and achieve the effect of enhancing parallel processing capability and integration, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

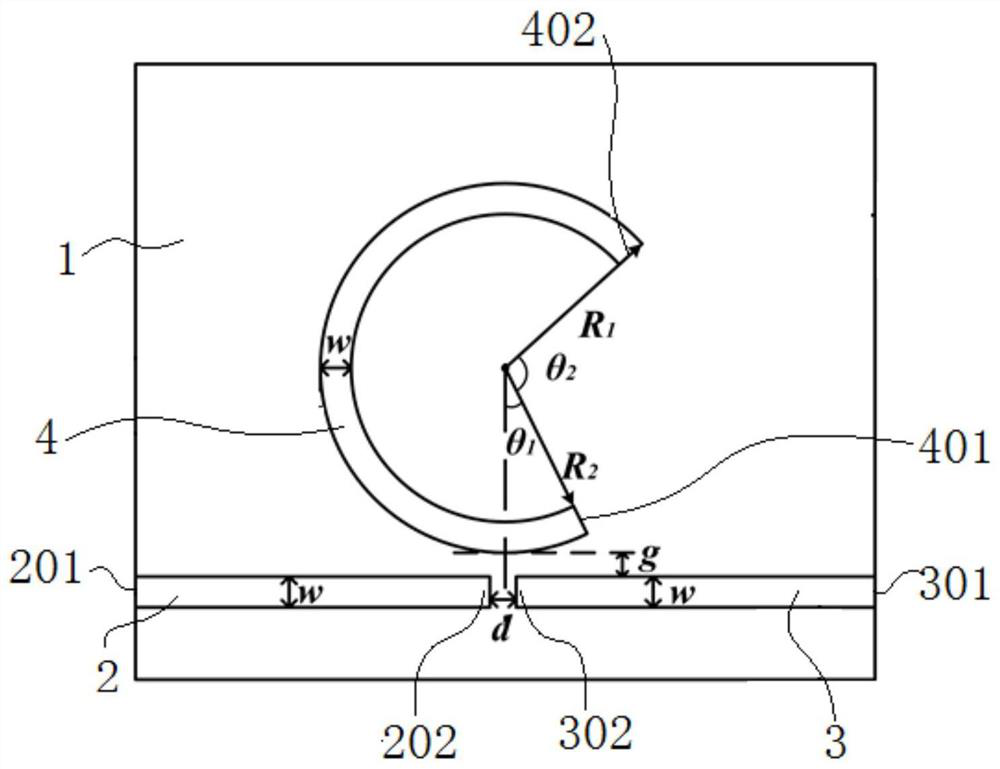

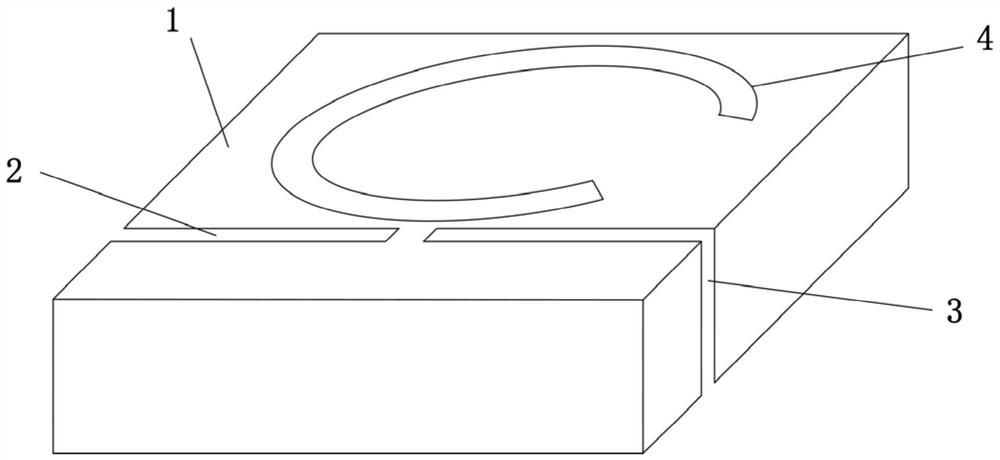

[0023] like Figure 1-2 Shown is an embodiment of a waveguide structure of a notched annular resonant cavity, including a substrate 1 and a first waveguide 2, a second waveguide 3 and a resonant cavity 4 disposed inside the substrate 1, the first waveguide 2 is from The first cavity extending from the side of the substrate 1 to the inside of the substrate 1; the second waveguide 3 extending from the side of the substrate 1 to the second cavity extending into the substrate 1, and the ends of the first cavity and the second cavity close to the side of the substrate 1 are both The openings are respectively the first openings 201 and 301, and the other ends are both closed ends, which are respectively the first closed end 202 and the second closed end 302; the resonant cavity 4 is a circular cavity with a gap, and the circular cavity The ends of are the third closed end 401 and the fourth closed end 402 respectively.

[0024] Wherein, the first waveguide 2 and the second waveguid...

Embodiment 2

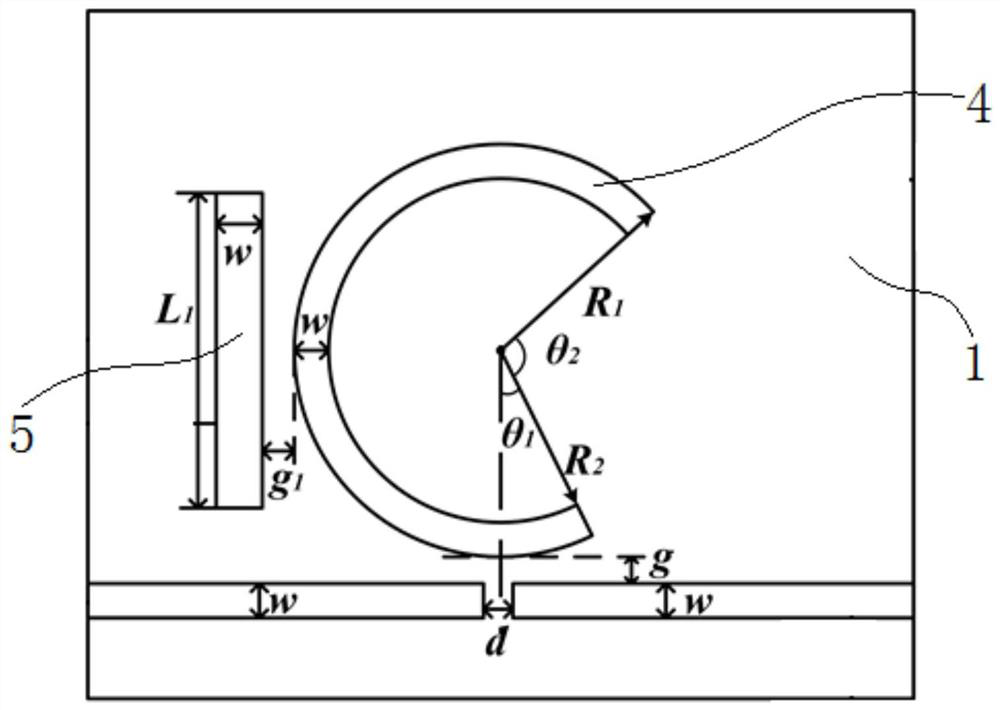

[0051] like image 3 Shown is another embodiment of the waveguide structure of a notched annular resonant cavity. The difference between this embodiment and the first embodiment is that a coupling resonant cavity 5 is provided on one side of the resonant cavity 4 . The dark mode provided by the coupled resonant cavity 5 interferes with the bright mode provided by the annular resonant cavity 4, so that more Fano resonance peaks can be formed.

[0052] The working principle or workflow of this embodiment: the parameters of the coupling resonant cavity 5 are set to:

[0053] L 1 =750nm, g 1 = 15nm. With such settings, new Fano resonance peaks with transmittances of 0.36, 0.36, and 0.23 can be formed at 109.8nm, 775nm, and 1183.4nm, respectively, and there are 12 Fano resonance channels in total. The wavelength and transmittance are shown in Table 6:

[0054]

[0055] Table 6 Wavelength and its corresponding transmittance

[0056] Of the Fano peaks that originally existed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com