Grinding amount analysis method based on grinding wheel end face grinding steel rail

A technology of end face grinding and analysis method, which is applied in the direction of measuring device, special data processing application, instrument, etc., can solve the problem that the quality of rail grinding is difficult to be guaranteed, and achieve the effect of not being affected by foreign objects on the rail surface, high accuracy, and convenient measurement operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

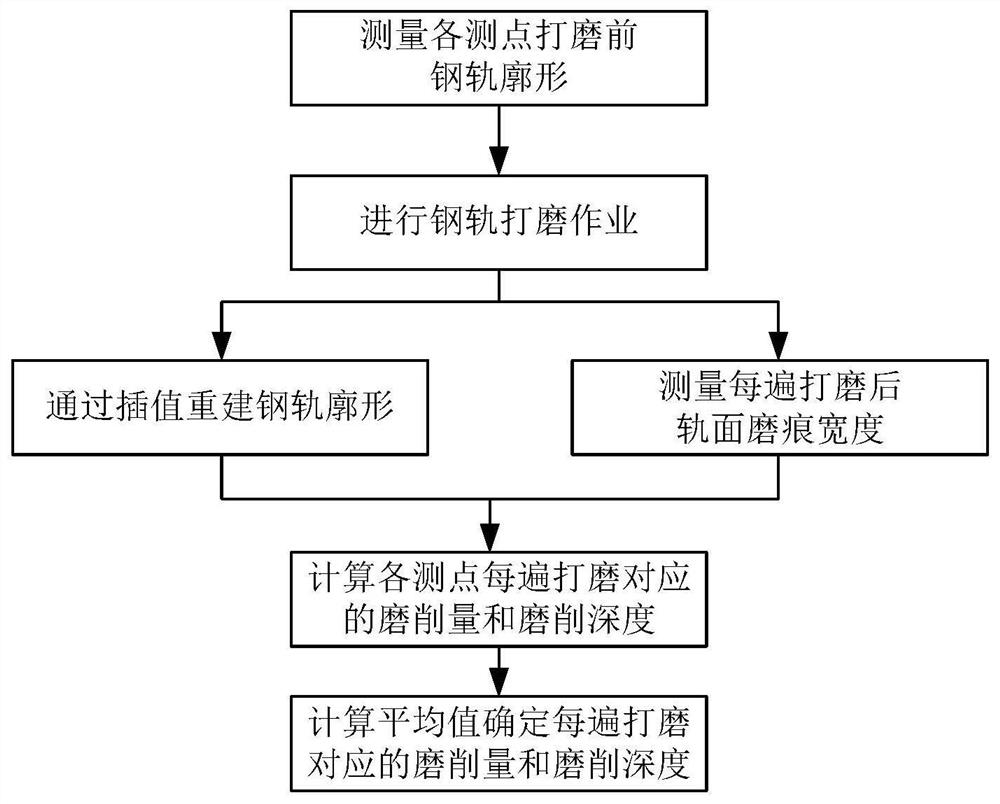

[0027] A grinding amount analysis method based on grinding wheel end grinding rail, such as figure 1 shown, including the following steps:

[0028] Step 1: Measure the rail profile before grinding.

[0029] Before grinding, select N measuring points at different positions along the longitudinal direction of the rail, and mark the positions of each measuring point. Use the rail profile measuring equipment to measure the profile of the rail before grinding. The profile discrete point data is denoted as RB i (i=1, 2, 3...N).

[0030] Step 2: Carry out rail grinding operations.

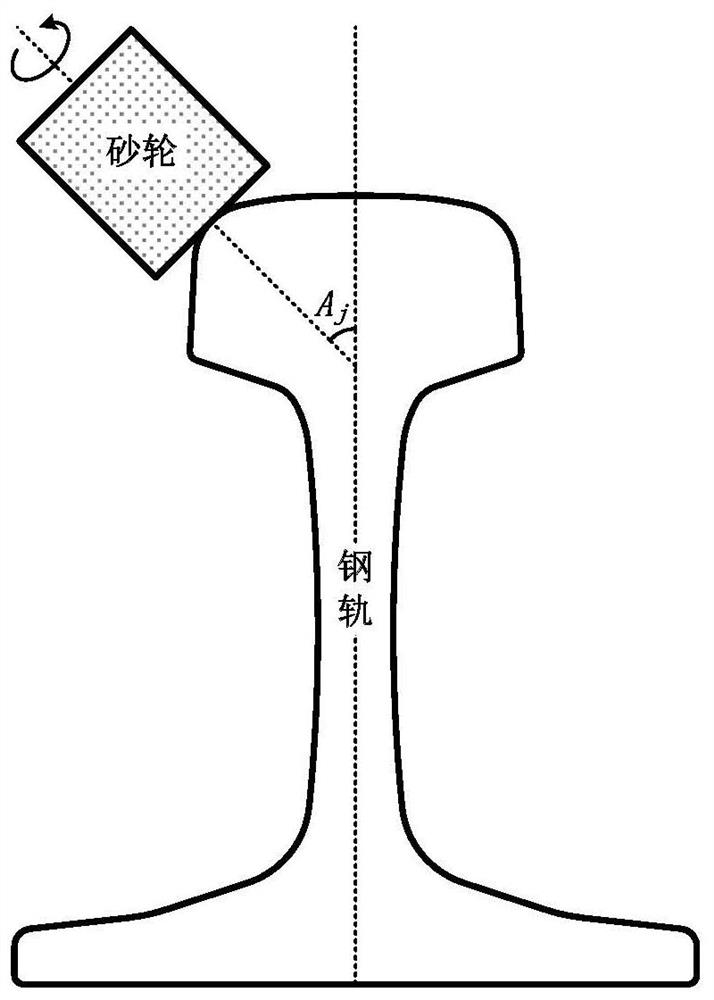

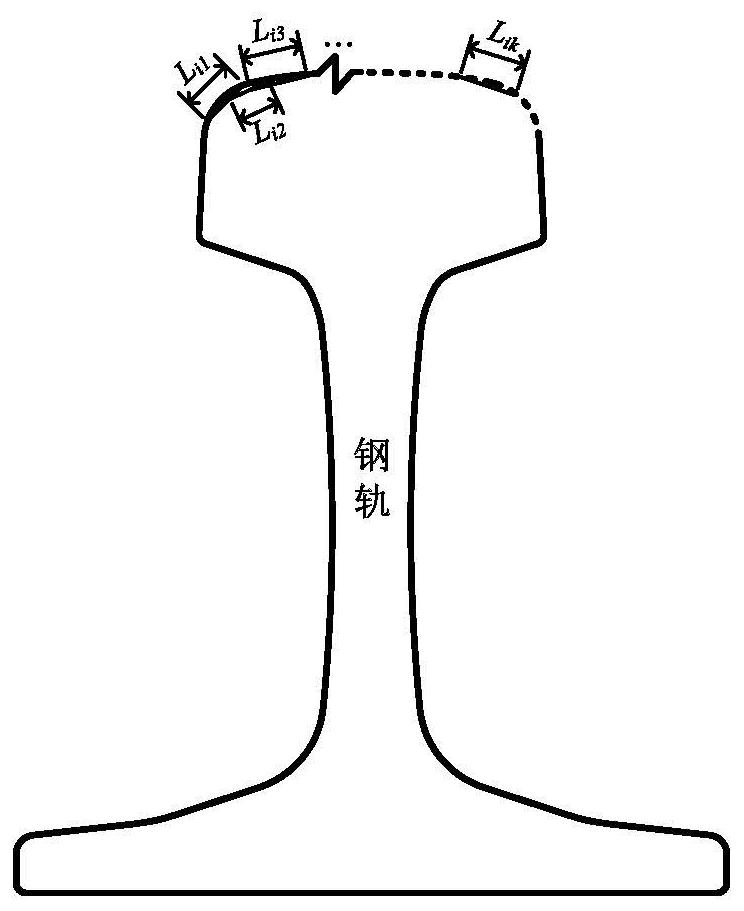

[0031] Set the working conditions of the grinding equipment (inclination angle of the grinding wheel, grinding pressure, rotating speed of the grinding wheel, travel speed, etc.), and use a single grinding wheel in the grinding equipment to grind the rail for M times. The situation is the same. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com