Thermonuclear fusion reactor superconducting coil heat shielding component and preparation method thereof

A technology of thermonuclear fusion reactors and superconducting coils, applied in the field of thermonuclear fusion reactors, can solve problems such as low vacuum sealing performance, low connection quality, and degradation of mechanical properties, so as to improve production efficiency, improve heat conduction efficiency, and benefit The effect of quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with accompanying drawing and embodiment the present invention is further introduced:

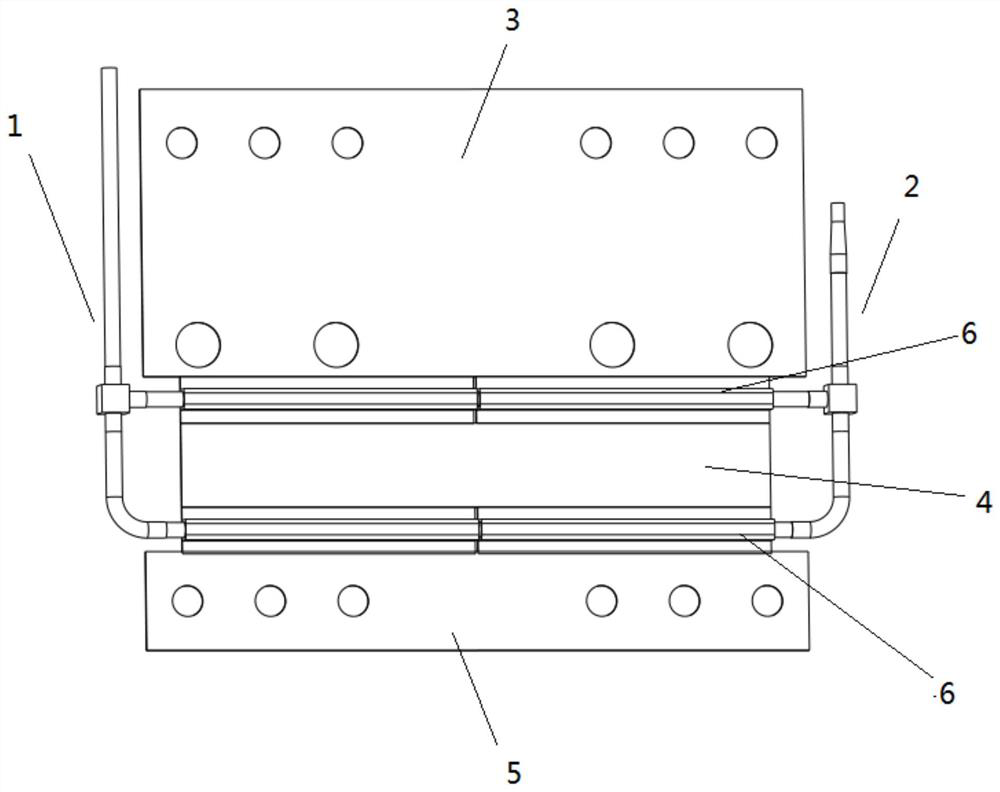

[0042] A thermonuclear fusion reactor superconducting coil heat shielding component, comprising: F-type tube A1, F-type tube B2, copper plate A3, copper plate B4, copper plate C5, copper chromium zirconium steel pipe brazing assembly 6; the copper plate A3 and copper plate B4 The copper chromium zirconium steel pipe brazing assembly 6 is connected between them, and the copper chromium zirconium steel pipe brazing assembly 6 is arranged between the copper plate B4 and the copper plate C5; the two ends of the copper chromium zirconium steel pipe brazing assembly A6 are respectively provided with F Type Tube A1 and Type F Tube B2.

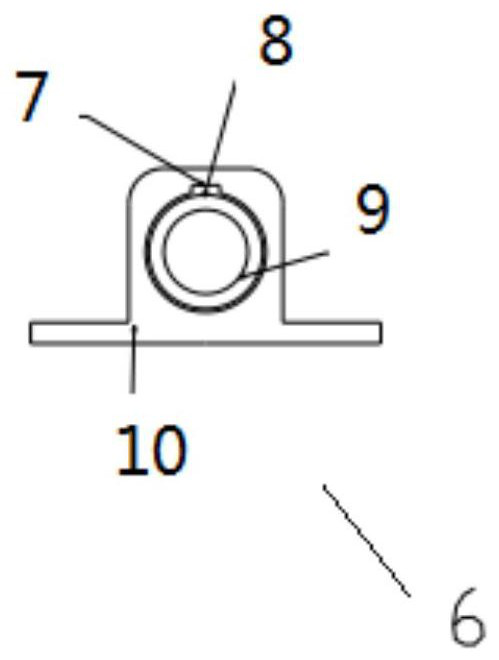

[0043] The copper chromium zirconium steel pipe brazing assembly 6 includes: copper chromium zirconium block 10, brazing material 7, filler tank 8 and steel pipe 9;

[0044] The copper-chromium-zirconium block 10 has a strip-shaped "con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roundness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com