Connector and method for manufacturing the same

A manufacturing method and connector technology, applied in the direction of contact manufacturing, connection, two-part connection device, etc., can solve the problems of increased manufacturing cost, unfavorable transmission characteristics, and many processes, so as to reduce manufacturing cost and suppress signal leakage , The effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

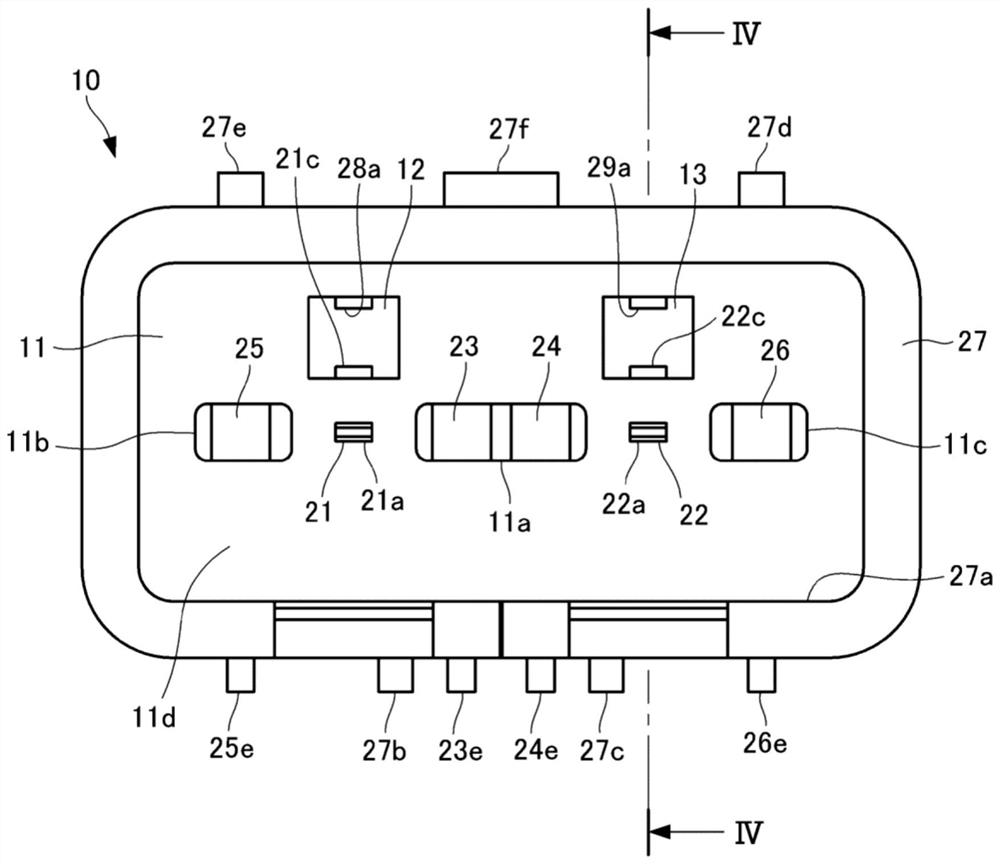

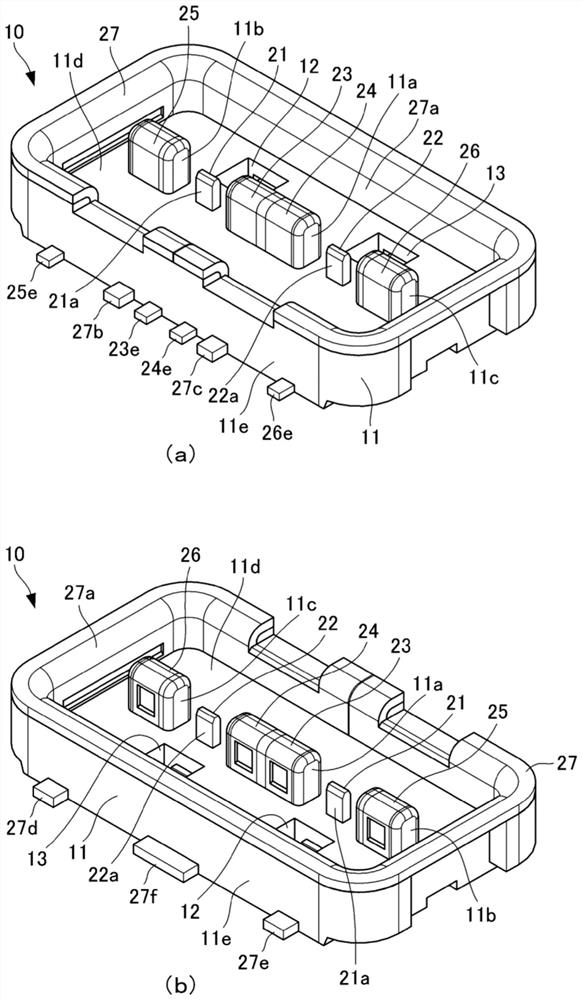

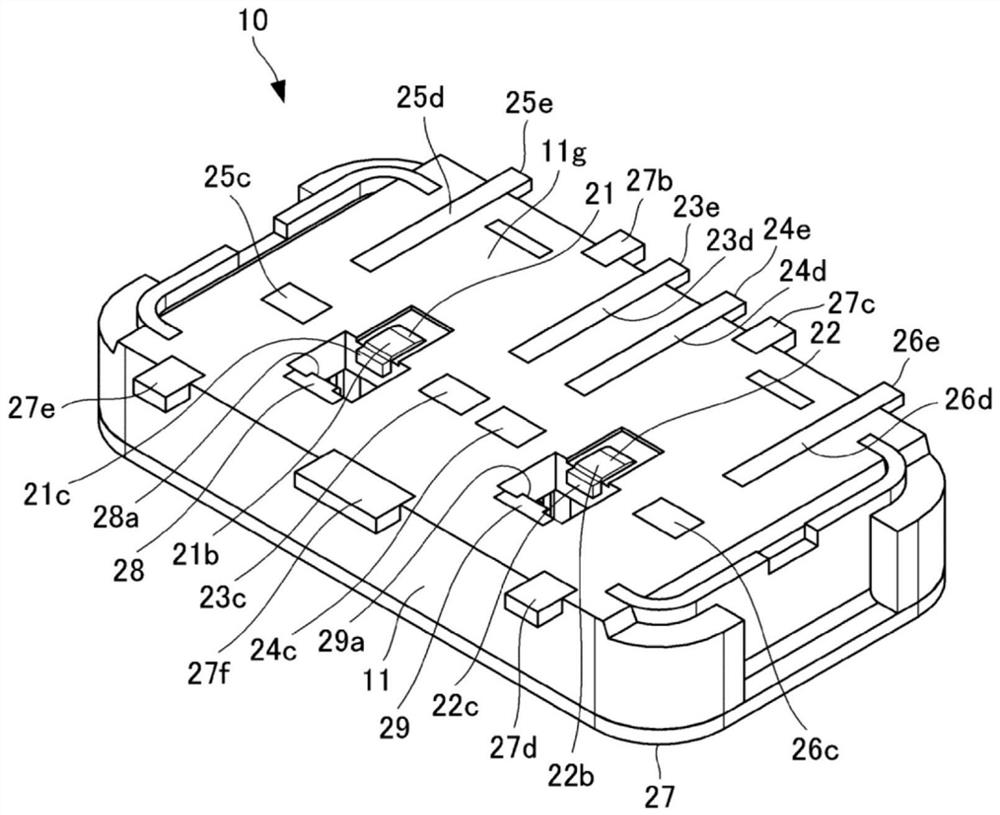

[0052] Figure 1 to Figure 4 Shows the plug 10 constituting the connector on the male side of this embodiment, Figure 6 ~ Figure 9 A receptacle 50 constituting a mating-side connector which is a female side to which the plug 10 is fitted is shown. The plug 10 and the receptacle 50 are arranged so as to be concave-convex-fitted with each other so that their corresponding terminals come into contact with each other and are electrically connected.

[0053] Hereinafter, the structures of the plug 10 and the receptacle 50 will be described, and then a method of manufacturing the plug 10 will be described.

[0054] (plug)

[0055] The plug 10 has a structure in which the center terminals 21, 22, the terminals 23, 24, 25, 26, and the ground conductor 27 are arranged and fixed on an insulating base formed in a rectangular plate shape in a substantially planar manner and at predetermined intervals. 11.

[0056] The center terminals 21 and 22 are terminals for high-frequency signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com