Fascia gun

A fascia and columnar technology, applied in the field of massage equipment, can solve the problems of unstable flexible transmission device, increased production cost, complex transmission structure, etc., achieve stable and reliable transmission structure, ensure product performance, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

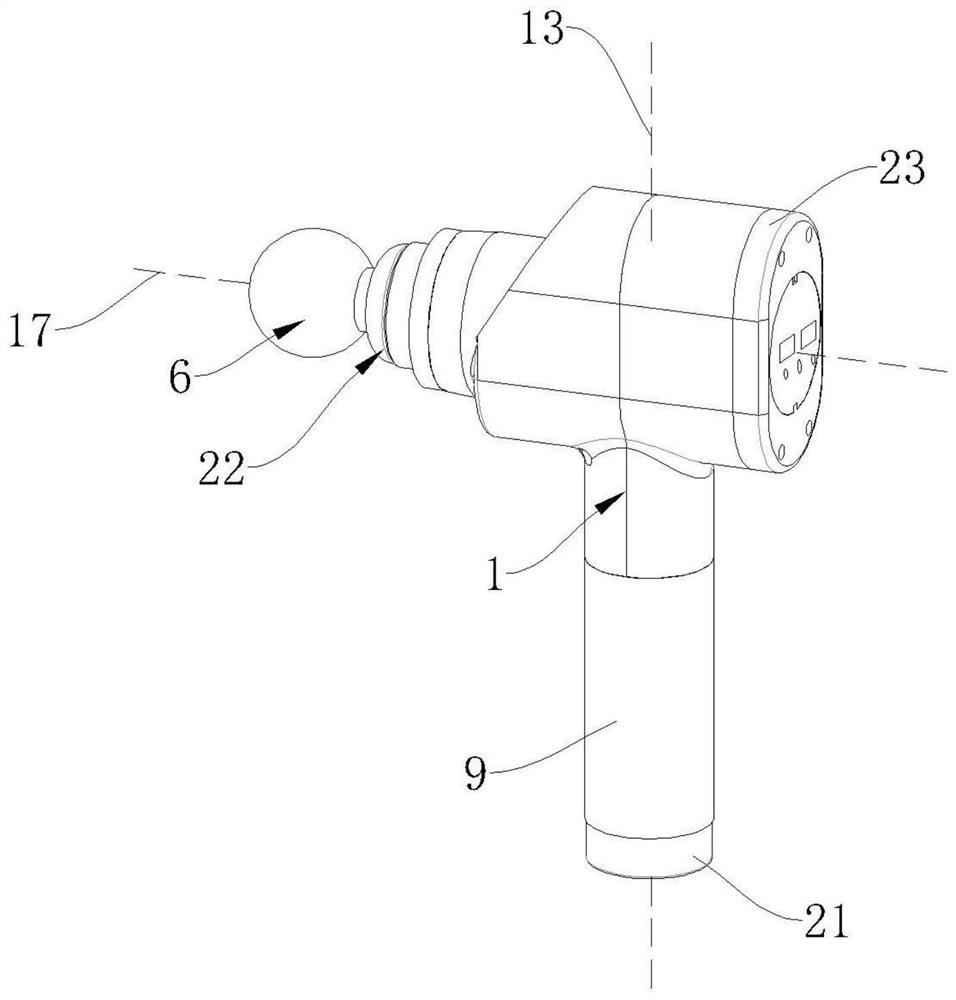

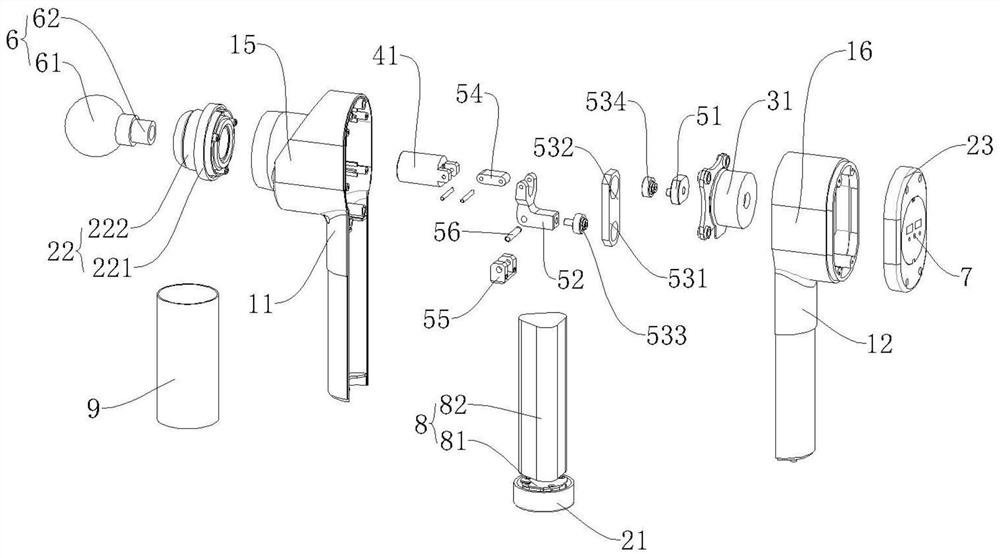

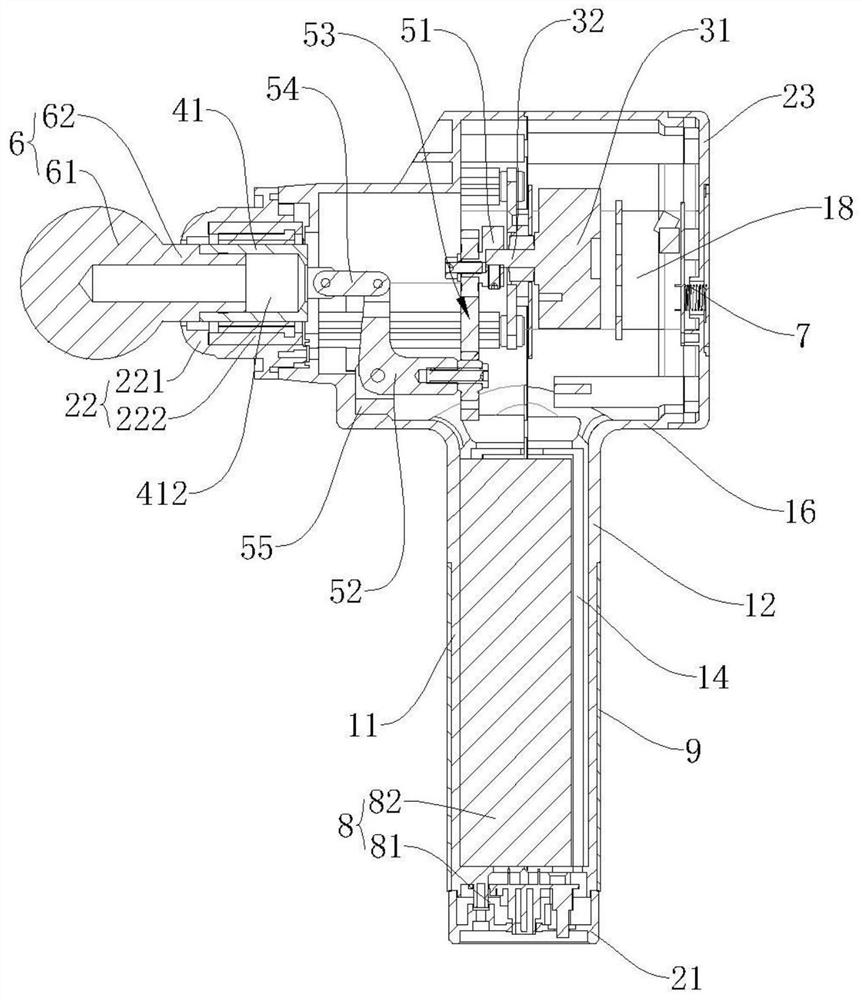

[0033] Such as Figure 1 to Figure 4 As shown, the fascia gun corresponding to a preferred embodiment of the present invention includes a housing 1, and the housing 1 includes a first housing part 11 and a second housing part 12, the first housing part 11 and the second housing part 12. The second housing parts 12 are joined to form an enclosure for a second cylindrical bore 14 extending around the longitudinal axis 13 . The first housing part 11 extends outwards with a third housing part 15, the second housing part 12 extends outwards with a fourth housing part 16, and the central axis of the third housing part 15 is aligned with the fourth housing part 16. The central axes of the cylinders are arranged in parallel to form an enclosure of a first cylindrical hole 18 extending around a transverse axis 17, the first cylindrical hole 18 and the second cylindrical hole 14 communicating with each other. One end surface of the second cylindrical hole 14 is spliced and covered by...

Embodiment 2

[0046] In this example, if Figure 5 As shown, the first part 531 is rotationally connected with the second part 532 , and the second part 532 is fixedly connected with the eccentric wheel 51 . Specifically, the first part 531 is partly embedded in the second part 532 and fixed through the first rotating shaft 535 , and the first part 531 can rotate around the first rotating shaft 535 . One end of the swing rod 52 is arranged approximately perpendicular to the first part 531, the first part 531 is installed with a first ball joint bearing 533, one end of the swing rod 52 is installed in the first ball joint bearing 533, and the eccentric wheel 51 is arranged approximately perpendicular to the second part 532, The second part 532 is equipped with a bearing 536, and the eccentric shaft of the eccentric wheel 51 is installed in the bearing 536. After the eccentric wheel 51, the double rotation degree of freedom connecting rod 53 and one end of the swing rod 52 are connected, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com