A kind of LED display module packaging method

A packaging method and a display module technology, which are applied to spraying devices, devices for coating liquid on the surface, coatings, etc., can solve the problems of small LED display modules, increased dispensing and injection errors, and poor device stability. , to achieve the effect of improving accuracy, improving stability and preventing colloidal solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

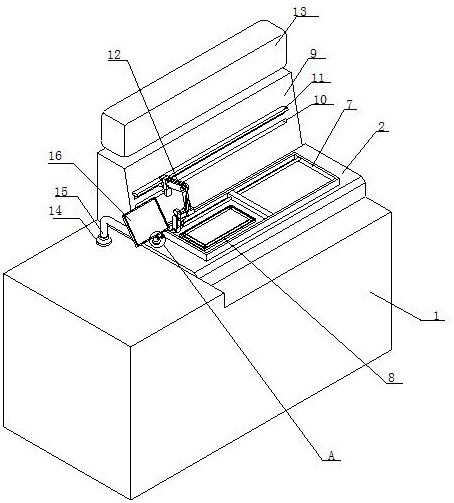

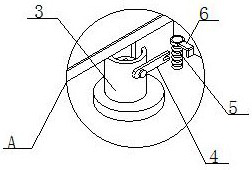

[0039] see Figure 1-5 , the present invention provides a technical solution: a LED display module packaging method, including a machine 1, the top of the machine 1 is provided with a boss 2, the bottom of the boss 2 is fixedly connected to the top of the machine 1, the boss The top of the insulation cylinder 3 is fixedly installed with the insulation cylinder 3, the inner wall of the insulation cylinder 3 is fixedly installed with a clamping platform, the outer wall of the insulation cylinder 3 is fixedly installed with an adjustment shaft, and the outer wall of the adjustment shaft is movably installed with a fixed rod 4. The top of the machine table 1 is set There is an air supply pipe 5, the outer wall of the air supply pipe 5 is flexibly connected with the inner wall of the machine 1, the end of the air supply pipe 5 far away from the machine 1 is provided with a limit flap 6, and the inner wall of the limit flap 6 is fixedly connected with the outer wall of the air supply...

Embodiment 2

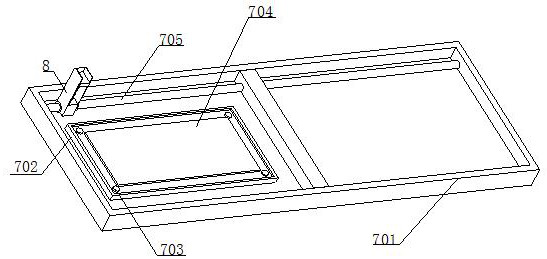

[0042] see Figure 1-Figure 4 , on the basis of Embodiment 1, the present invention provides a technical solution: the top of the boss 2 is fixedly installed with a packaging base 7, the inside of the packaging base 7 includes a supporting platform 701, and the inner wall of the supporting platform 701 is fixedly installed with a mounting The platform 702 and the interior of the installation platform 702 are provided with a positioning column 703 , the bottom of the positioning column 703 is fixedly connected with the inner wall of the installation platform 702 , and the inner wall of the installation platform 702 is clamped with a thermal insulation board 704 . The inner wall of the mounting table 702 is fixedly equipped with a lead screw 705, and the outer wall of the lead screw 705 is movably equipped with a support platform 8. The inside of the support platform 8 includes a connecting cylinder 801, and the outside of the connecting cylinder 801 is provided with a fixed plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com