Crystal grinding machine

A grinding machine and crystal technology, applied in the direction of grinding machine tools, grinding devices, working carriers, etc., can solve the problems of unsatisfactory work efficiency and stability, inconvenient operation, unreasonable design of grinding devices, etc., to improve the grinding effect , Improve the grinding effect and improve the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further explain the technical solution of the present invention, the following will be described in detail in conjunction with the examples. In the drawings of the present invention, for multiple components with the same structure, some drawings only show one of them.

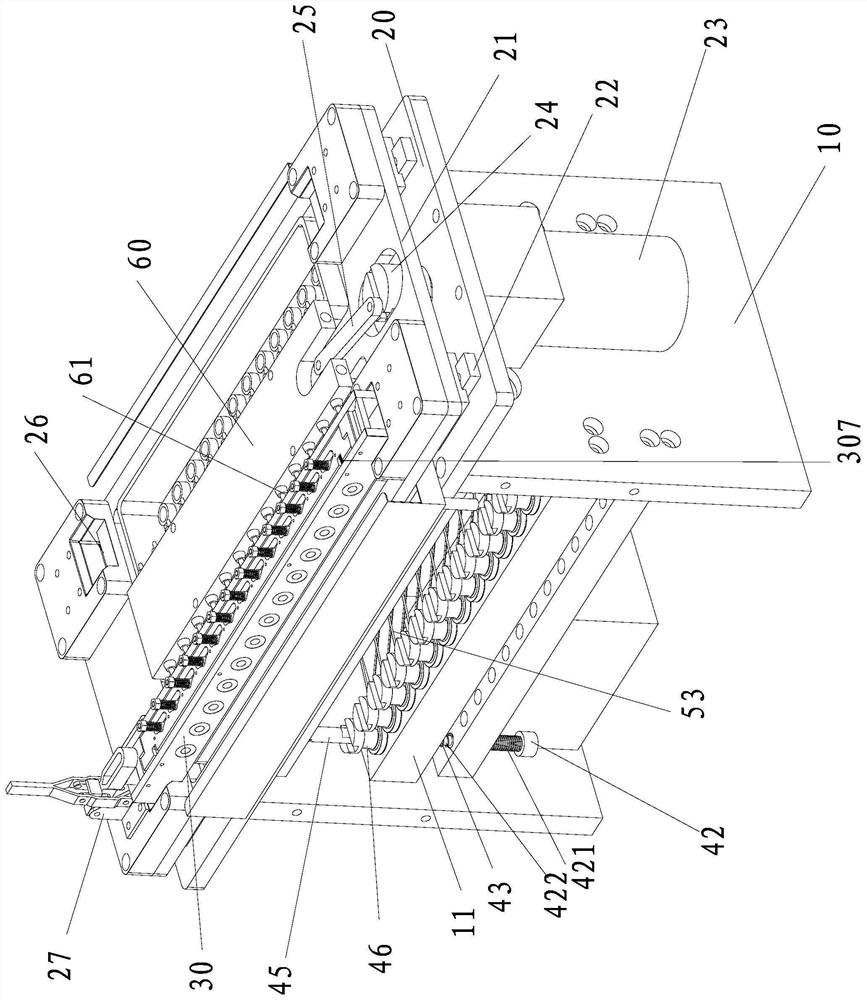

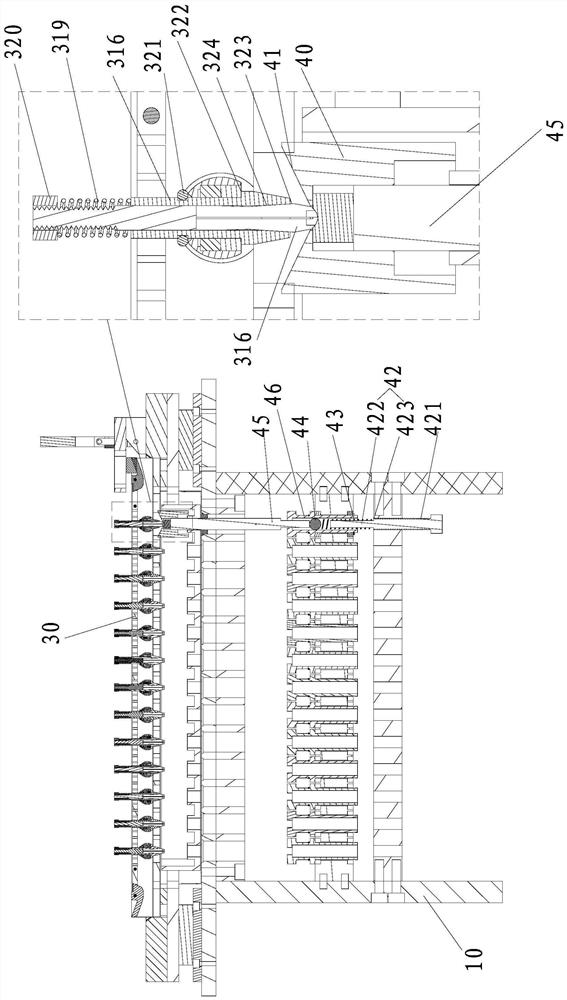

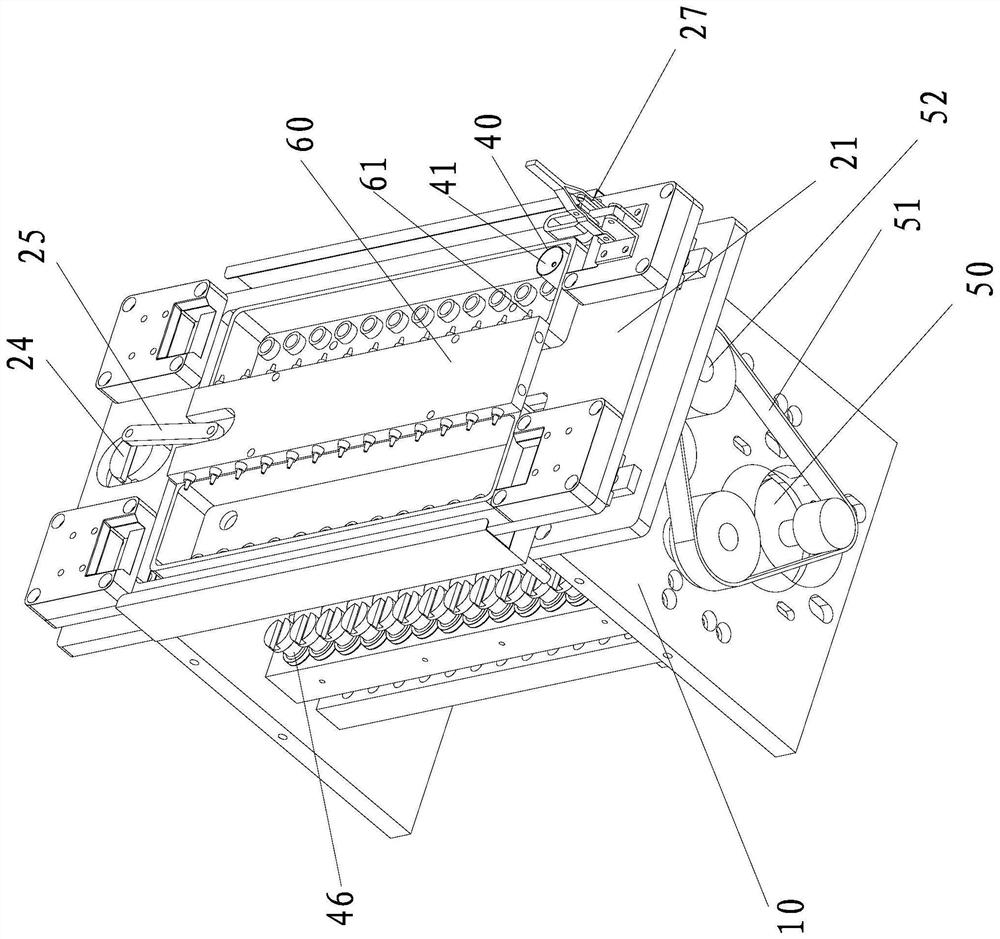

[0051] refer to Figure 1 to Figure 5 , a crystal grinding machine, comprising a frame 10, a workbench 20 arranged on the frame 10, a slide plate 21 arranged on the workbench 20, a first drive mechanism for driving the slide plate 21 to slide on the workbench 20, for The fixture 30 for clamping the workpiece to be processed, the plurality of grinding discs 40 set corresponding to the clamping fixture 30 and the second drive mechanism for driving the grinding disc 40 to rotate, the workbench 20 and the slide plate 21 are all arranged along the horizontal direction, and the grinding machine of the present invention can be used For processing columnar optical crystals, a hemispherical surface i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com