Printing device for surfaces of lithium batteries

A printing device and lithium battery technology, applied in the field of printing devices, can solve problems such as being easily eliminated by the market, unfavorable for diversified production of enterprises, unfavorable for sustainable development of enterprises, etc., and achieve the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

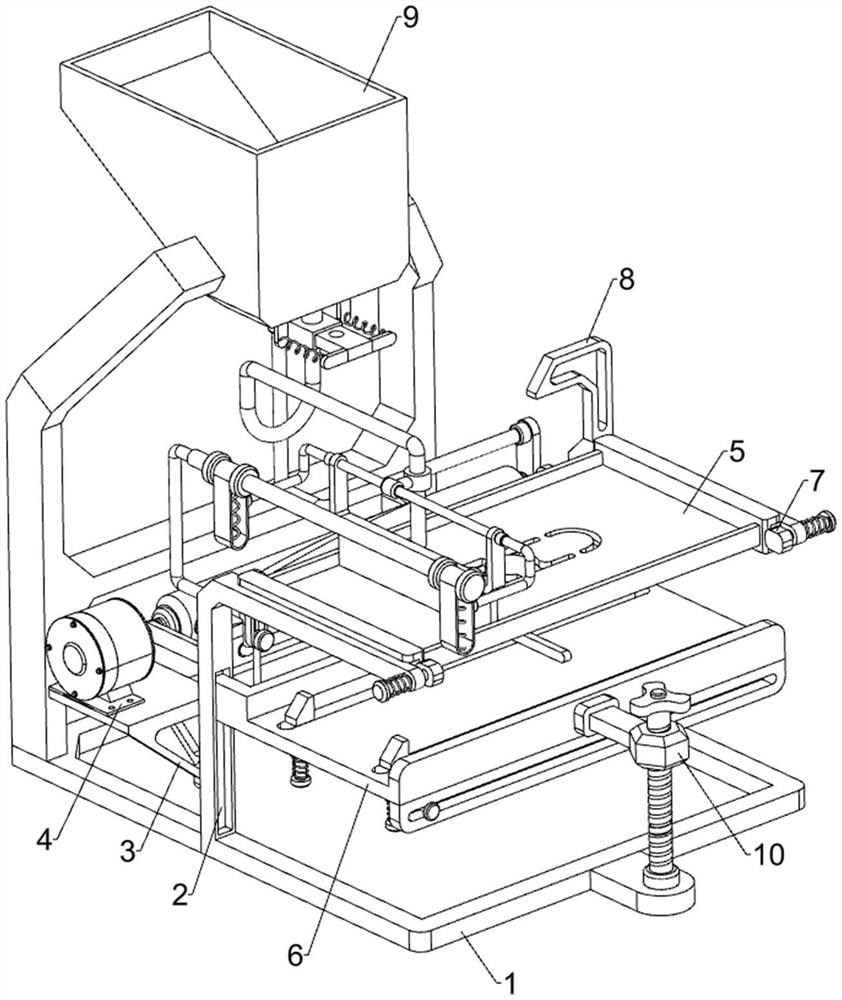

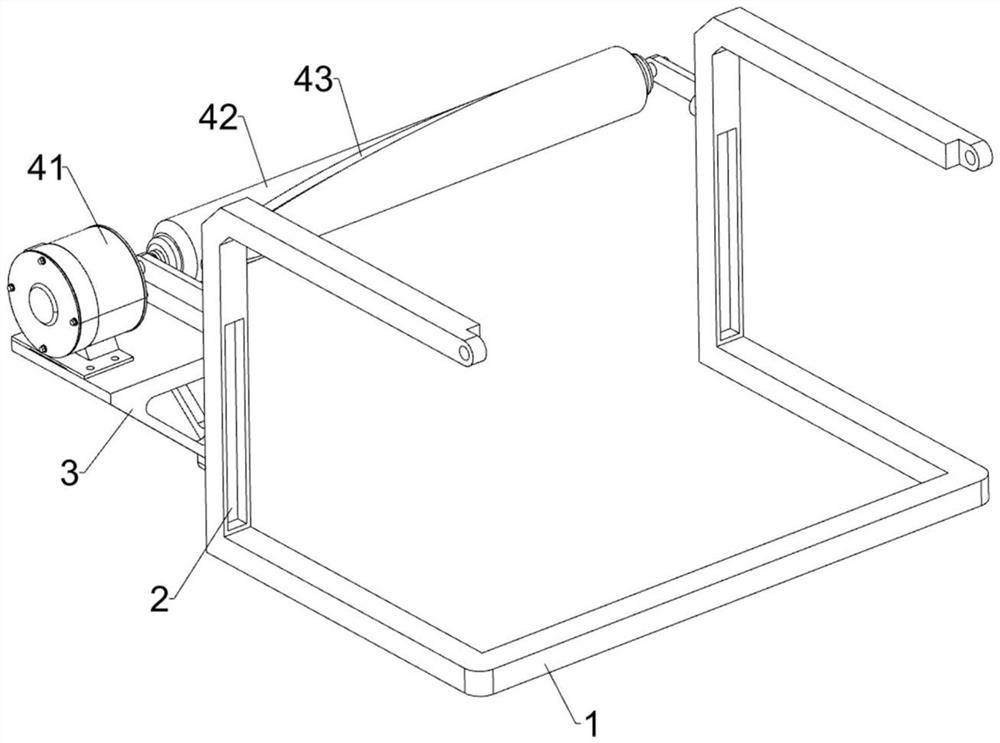

[0028] A printing device for the surface of lithium batteries, such as Figure 1-3 As shown, it includes a frame 1, a mounting plate 3, a drive assembly 4 and a printing assembly 5. The front and rear sides of the middle of the frame 1 are provided with chute 2, and the front side of the frame 1 is fixed with a mounting plate 3 by bolts. , the upper side of the mounting plate 3 is installed with a drive assembly 4, and the upper side of the right part of the frame 1 is installed with a printing assembly 5.

[0029] When printing a lithium battery, put the lithium battery under the printing assembly 5, then apply the paint on the printing assembly 5, start the driving assembly 4, and the driving assembly 4 will drive the printing assembly 5 to operate, and at the same time control the printing of the lithium battery. As the component 5 rotates, the printing component 5 will print the lithium battery, and then repeat the above operation to print another lithium battery. When all...

Embodiment 2

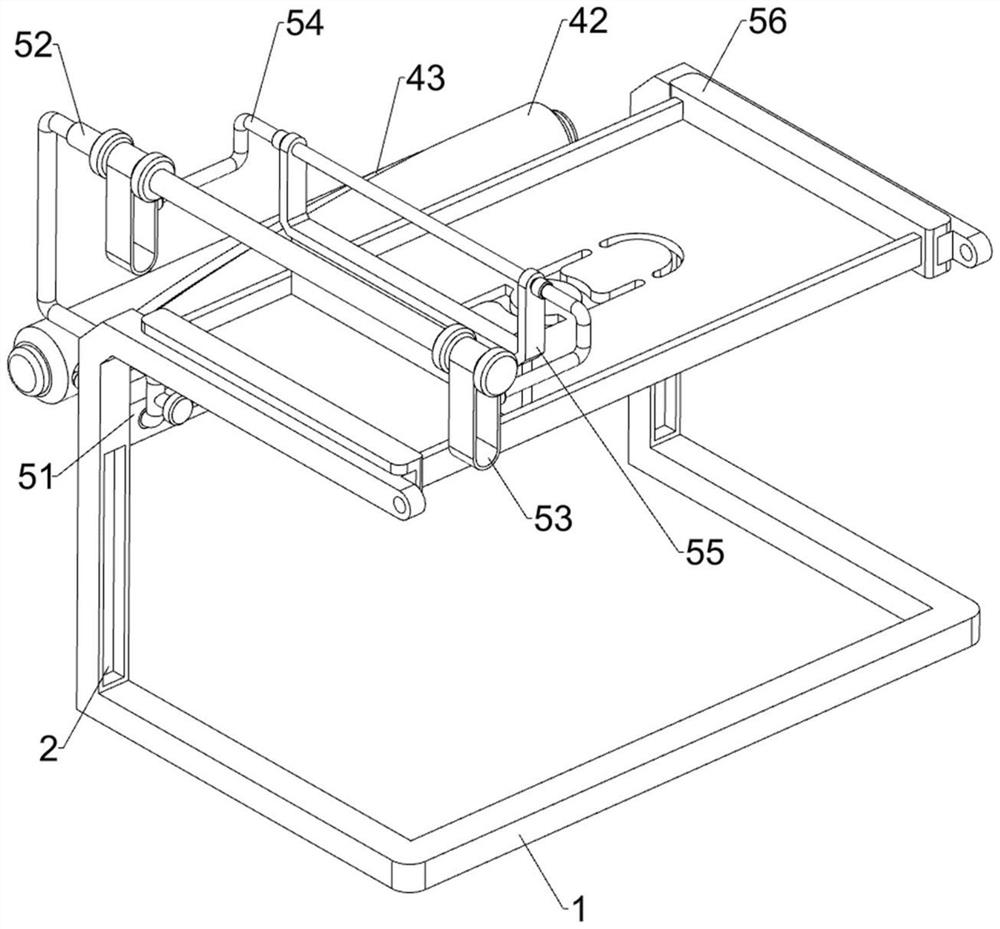

[0035] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, a placement assembly 6 is also included, and the placement assembly 6 includes a placement plate 61, a second guide rail 62, a blocking plate 63, a right-angle rod 64, a slide bar 65, a wedge block 66 and a first spring 67, between the chute 2 The sliding type is provided with a placement plate 61, the first special-shaped rod 52 is slidingly connected with a second guide rail 62, the rear side of the second guide rail 62 is connected with a blocking plate 63, and the lower side of the second guide rail 62 is connected with a right-angle rod 64, the right-angle The left and right sides of bar 64 are all slidably installed with slide bar 65, and the upper side of slide bar 65 is welded with wedge block 66, and wedge block 66 cooperates with placement plate 61, is connected with first spring between slide bar 65 and right-angle bar 64 67.

[0036] Cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com