Heavy object carrying device for logistics

A technology for handling devices and heavy objects, which is applied in the field of heavy object handling devices for logistics, which can solve the problems of manpower consumption, low handling efficiency, and high handling strength, and achieve the effect of avoiding manpower consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

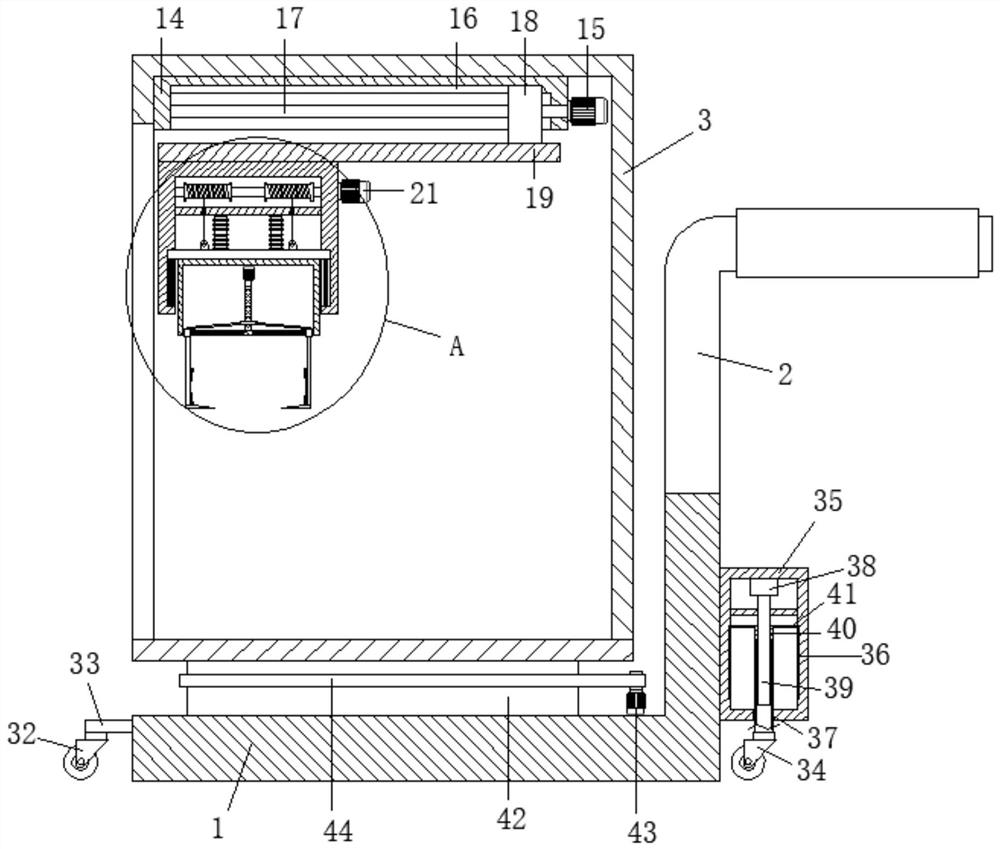

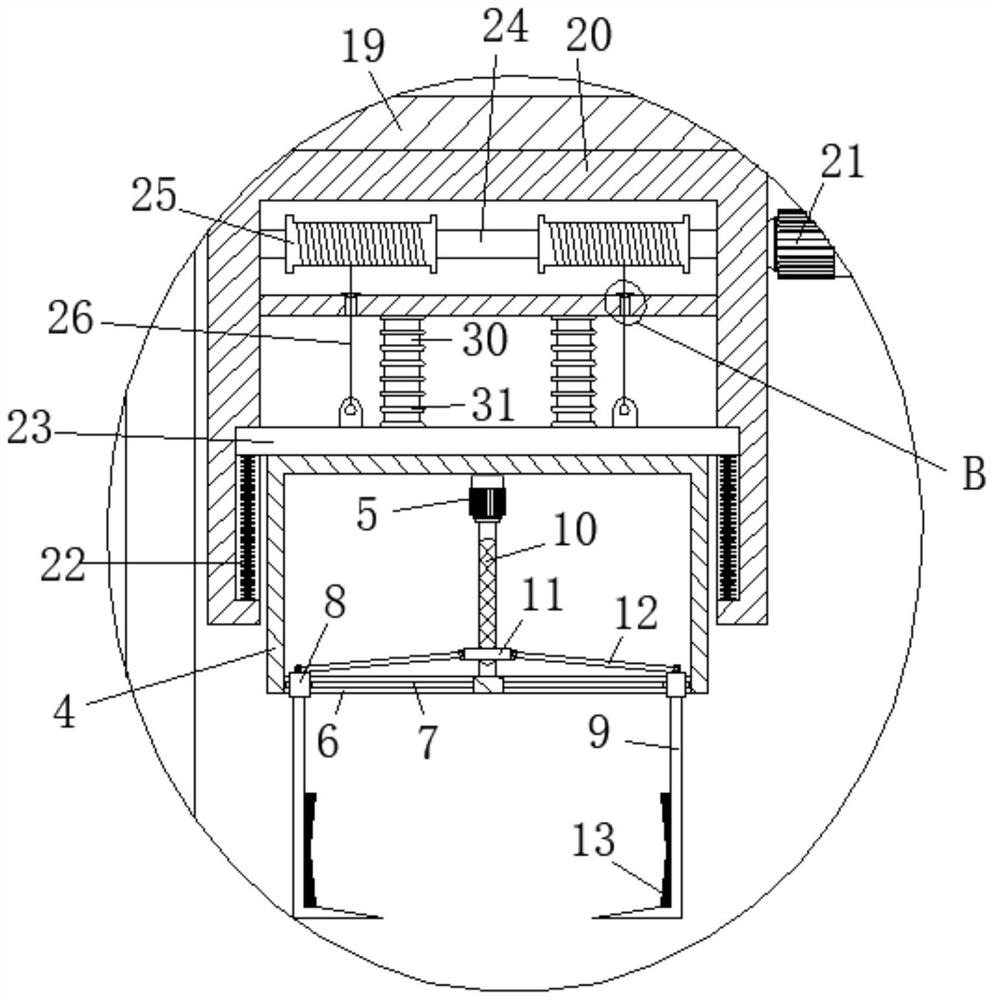

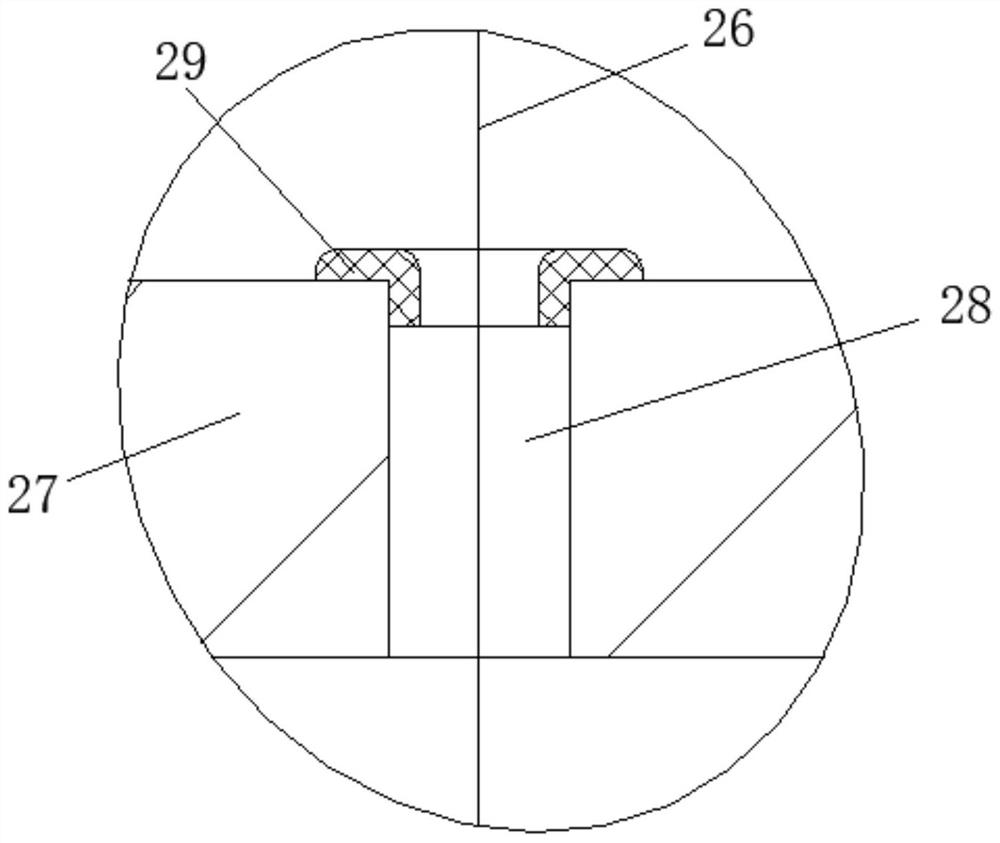

[0021] see Figure 1-3 , a heavy object handling device for logistics, including a handling base 1, a push handle 2 and a moving assembly, the moving assembly is arranged on both sides of the handling base 1, and the pushing handle 2 is fixedly installed on the side wall of the handling base 1 , the handling base 1 is provided with a mounting frame 3 with one side open, and the mounting frame 3 is provided with a heavy object clamping assembly and a horizontal adjustment assembly and a longitudinal adjustment assembly for driving the position of the heavy object clamping assembly to move. Assembly, the horizontal adjustment assembly is arranged on the top inner wall of the installation frame 3, the longitudinal adjustment assembly is arranged on the horizontal adjustment assembly, the weight clamping assembly is arranged on the longitudinal adjustment assembly, and the weight clamping assembly includes The positioning frame 4 arranged on the longitudinal adjustment assembly, t...

Embodiment 2

[0029] This embodiment is further improved on the basis of the embodiment, and the improvement is that: the transfer base 1 is provided with a rotating assembly that drives the installation frame 3 to rotate, and the rotating assembly includes a rotating column 42 that is rotatably installed on the transfer base 1 And the rotating motor 43 that is fixedly installed on the carrying base 1, the transmission between the rotating column 42 and the rotating motor 43 is connected by a belt pair 44, and the mounting frame 3 is fixedly installed on the rotating column 42; by setting the rotating column 42 and Rotating the motor 43 facilitates the adjustment of the direction of the L-shaped clamping plate 9, further realizes the multi-directionality of heavy object handling, and improves the applicability of the overall device.

[0030] The working principle of this embodiment is: by setting the rotating column 42 and the rotating motor 43, it is convenient to adjust the direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com