Double-layer hull opening and pumping device using rov cooperative operation

A hull and drilling machine technology, applied in transportation and packaging, underwater operation equipment, ships, etc., can solve problems such as single function, lack of ROV collaborative operation ability, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

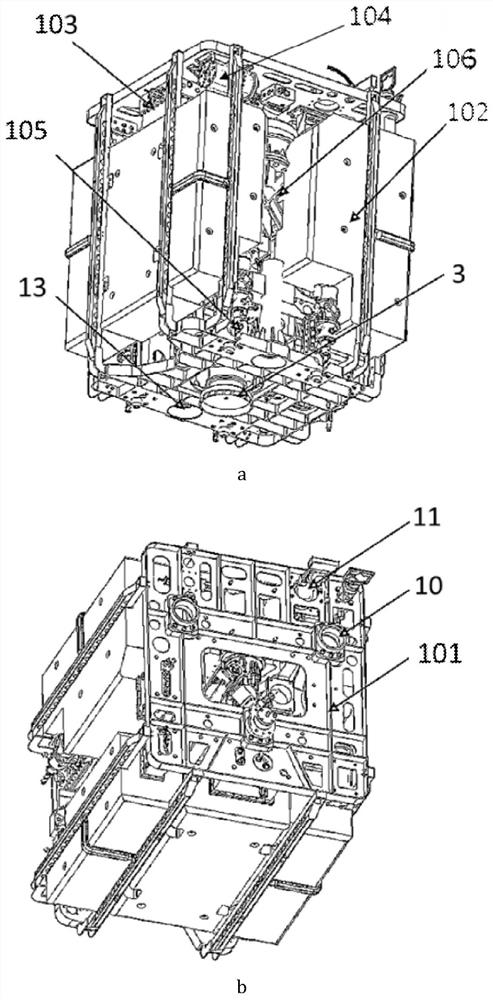

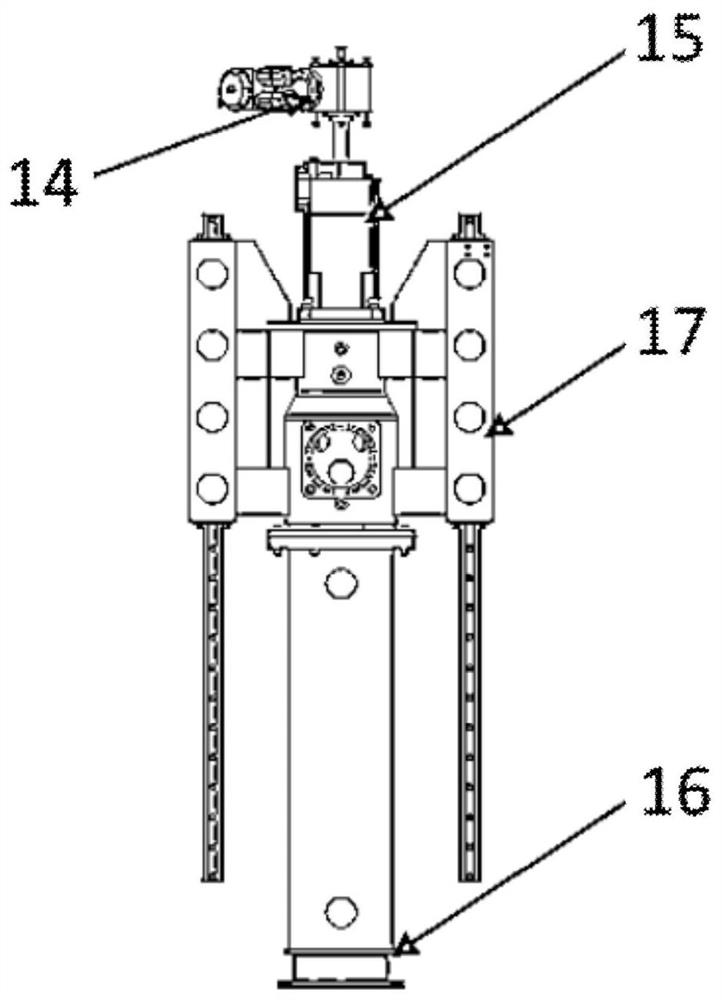

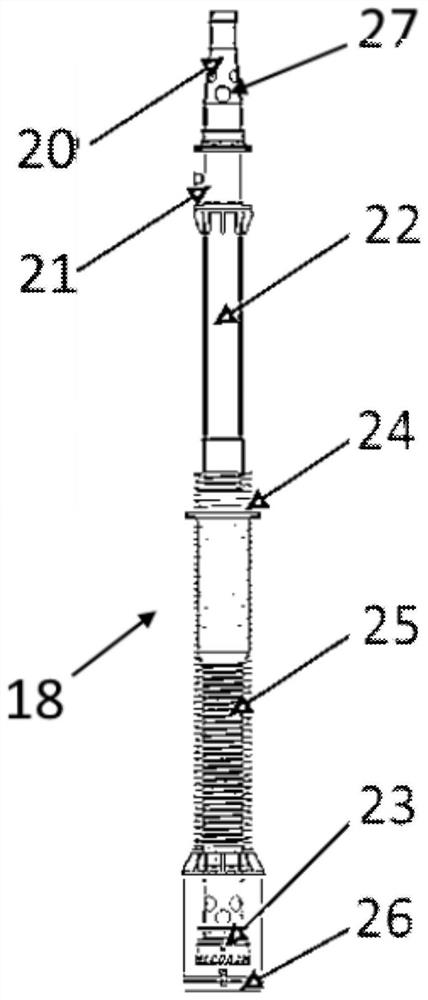

[0028] Such as Figure 6 to Figure 10 As shown, this embodiment includes: a hole tapping machine body 1, a base plate 2, an outer layer hole cutter 3 and an inner layer hole cutter assembly 4, and an ROV cooperating with the hole tapping machine body 1, wherein: the hole tapping machine body 1 is docked and locked with the base plate 2 through the base plate installation system 105 on it, and the outer layer tool 3 or the inner layer hole tool assembly 4 is connected with the main drilling machine 106 of the hole tapping machine body 1, and the hole tapping machine body 1 passes through the TDU The interface unit 10 is connected to the ROV and transmits control information, electrical energy or hydraulic energy through a wet plug electrical connector 11 .

[0029] Such as figure 1 As shown, the drilling machine body 1 includes: a main frame 101, a buoyancy block 102, a hydraulic valve control system 103, a compensation system 104, a monitoring system, a template installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com