Large-caliber pipeline local leaking stoppage device and method

A technology for large-diameter pipelines and plugging devices, which is applied in the direction of pipe elements, pipes/pipe joints/fittings, mechanical equipment, etc., and can solve the problems of unstable construction quality, high processing cost, and large material occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

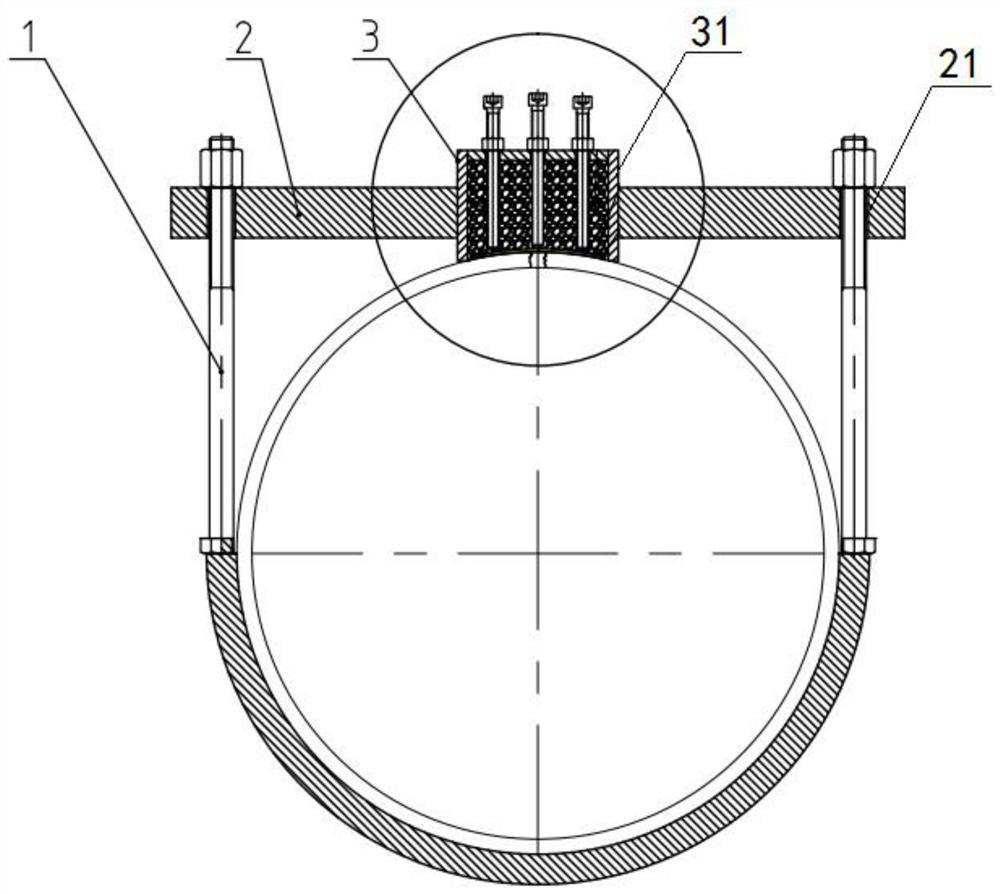

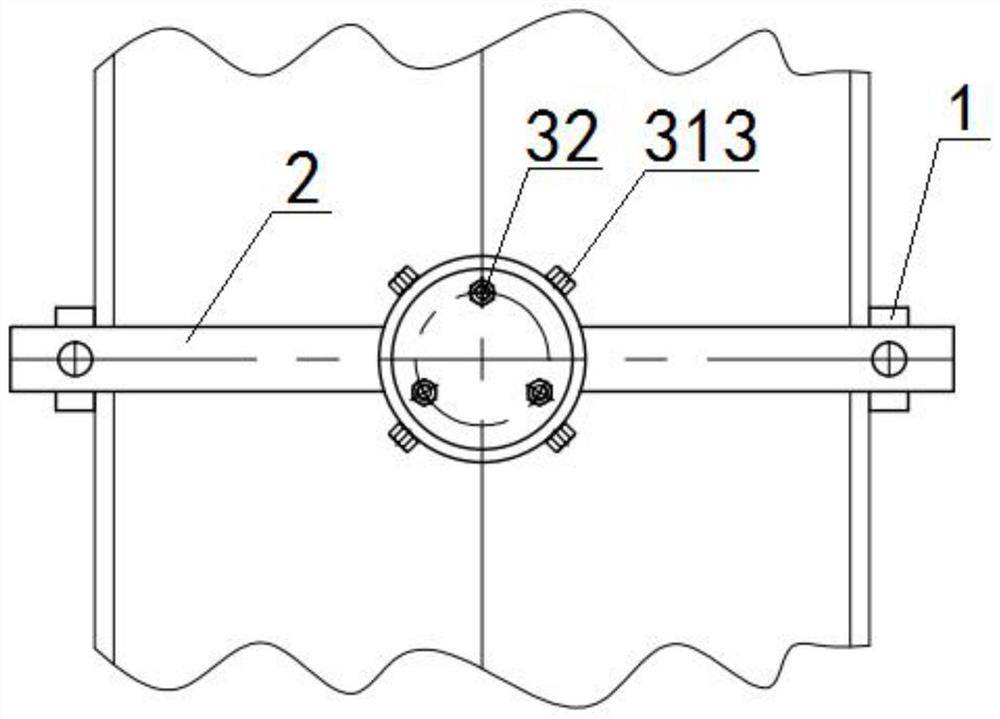

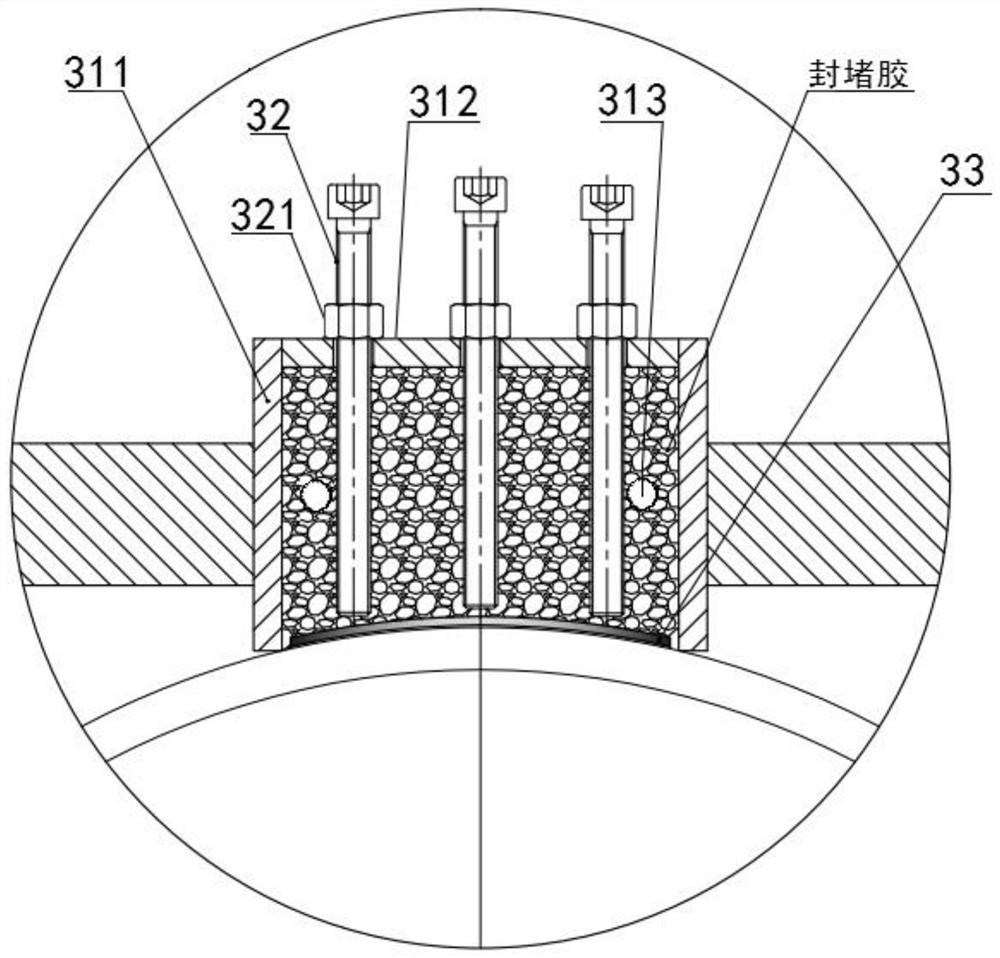

[0032] The invention relates to a local leakage plugging device for large-diameter pipelines, comprising: a U-shaped clamp 1, a crossbeam 2 and a plugging device 3. The two sides of the plugging device 3 are provided with crossbeams 2, and the beam 2 cooperates with the U-shaped clamp 1. It is set on the pipeline, and the sealing device 3 is set at the position where the leakage occurs on the pipeline. This setting solves the problems of large material occupation, high processing cost, and poor operability. The structure achieves the effect of saving material and processing costs and simple operation.

[0033] The crossbeam 2 and the plugging device 3 are welded and fixed, and the crossbeam 2 is provided with a bolt hole 21, and the crossbeam 2 is installed on the opening end of the U-shaped card 1 through the bolt hole 21, so that the problem of unstable construction quality is solved by setting the crossbeam. 2. The bolt hole is set on the opening end of the U-shaped card an...

Embodiment 2

[0039] A method for local leakage plugging of large-diameter pipelines, comprising the steps of:

[0040] S1: On-site measurement of the relevant dimensions of the leakage point, and the production of suitable sealing devices and fixtures by measuring the relevant dimensions of the leakage point in advance;

[0041] S2: According to the structure in the figure, the sealing device and fixture are processed and manufactured, and the waste of materials and sealing glue is avoided by processing and manufacturing the device and fixture with appropriate size, and the sealing effect is improved;

[0042] S3: Set the U-shaped clamp 1 at the leaking place of the pipeline. The curved part of the U-shaped clamp 1 completely fits the outer wall of the pipeline, and the open end of the U-shaped clamp 1 is two bolts. This setting achieves a stable clamping effect;

[0043] S4: Place the top pressure thin plate 33 at the leakage point of the pipeline. The top pressure top pressure thin plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com