Vibration sensing system with cooling shell

A vibration sensing system and vibration sensor technology, applied in cooling/ventilation/heating renovation, measuring devices, instruments, etc., can solve the problems of vibration sensor overtemperature failure, etc., to reduce thermal radiation, improve cooling effect, and reduce heat conduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

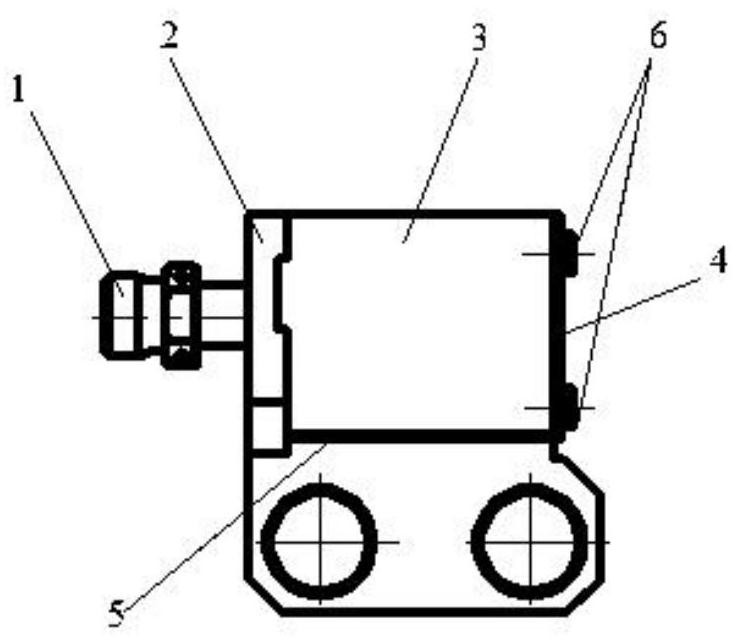

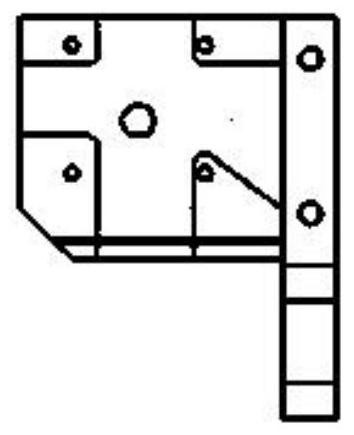

[0026] Such as Figure 1(a)-Figure 1(d) Shown is a cooling shell of a vibration sensing system with a cooling shell of the present invention, including a connecting plate 3 and an ear seat 2; the connecting plate 3 is provided with a casing mounting hole; the ear seat is installed On one side of the connection plate, a heat radiation blocking plate 5 is arranged under the ear seat, a heat radiation blocking plate 4 is arranged behind the ear seat, a pipe joint 1 is arranged outside the ear seat, and a sensor installation hole is opened in the center of the ear seat , there is a cooling airway slot around the sensor installation hole, and a process gas nozzle 8 is arranged on the side of the sensor installation hole.

[0027] The ear seat that is in direct contact with the sensor probe is specially designed, adopts a channel air-cooled structure, the ear seat is opened for ventilation and cooling, and the side that contacts the sensor is slotted to enhance the heat exchange bet...

Embodiment 2

[0029] The present invention adopts air-cooled grooved lugs and process gas nozzles for diffusing the flow field of cooling air to cool the sensor in all directions, and a thin support plate is arranged around the sensor to greatly reduce heat radiation while reducing heat conduction. Compared with the traditional sensor base, the present invention adopts multiple cooling methods in parallel to improve the cooling effect. After practical application verification, the present invention can greatly reduce the surface temperature of the sensor, effectively avoiding the problem that the measurement accuracy of the sensor is affected by excessive temperature.

[0030] The structure of the process gas nozzle arranged on the left side of the sensor and its diffusion of the convection field are shown in Fig. 4(a), Fig. 4(b) and Fig. 4(c). A total of 8 slots with a width of 1 mm are opened on the side and the side, the length of the end slot is 2 mm, and the length of the side slot is 3...

Embodiment 3

[0032] Figure 3(a), Figure 3(b) and Figure 5 Shown is a vibration sensing system with a cooling shell of the present invention, including a cooling shell and a vibration sensor 7; the cooling shell includes a connecting plate and an ear seat; the connecting plate is provided with a casing mounting hole; The ear seat is installed on one side of the connecting plate, a heat radiation blocking plate is arranged under and behind the ear seat, a sensor mounting hole is opened in the center of the ear seat, and cooling air passage slots are arranged around the sensor mounting hole. A process gas nozzle is arranged on one side of the sensor installation hole; the vibration sensor is fixed on the ear seat through the sensor installation hole, and the probe of the vibration sensor is arranged on the side of the process gas nozzle; the ear seat is provided with a pipe joint , the cooling air flow passes through the pipe joint and impacts the bottom of the vibration sensor, and then dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com